Device for collection abandoned films

A film and base technology, applied in the field of devices that can collect waste films, can solve the problems of easy heating of driving equipment, achieve the effects of convenient transportation and transfer, ensure stability, and facilitate replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

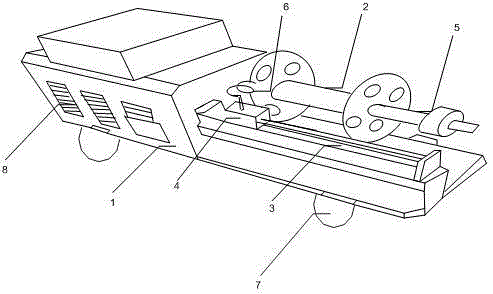

[0018] Such as figure 1 As shown, in the process of film processing, the trimmed waste corners are connected to the reel 2 through the guide ring 6 on the guide mechanism 4. Driven by the servo motor, the reel 2 rotates with the rotating shaft 5 to start collecting the corners ; When a certain amount of waste material is collected at one end of the reel 2, the waste material is wound on the other end of the reel 2 by adjusting the guide mechanism 4 to move on the guide rail 3, so that the waste material is evenly distributed on the reel 2, which is convenient for rolling Replacement of the barrel 2 and disposal of waste materials; multiple universal wheels 7 arranged at the bottom of the base 1 can make the mechanism move around quickly, which is convenient for the transportation and transfer of the mechanism, and also reduces the labor intensity of the workers. The brake installed on it can fix the universal wheel 7 when the device is running, so as to avoid the displacement ...

Embodiment 2

[0020] Such as figure 1 As shown, the reel 2 and the rotating shaft 5 are detachably connected. When the collected film waste is full, the reel 2 is replaced by rotating the locking bolt on the rotating shaft 5 to process the collected waste.

Embodiment 3

[0022] Such as figure 1 As shown, because the time required for cutting the film into different shapes is different, it is necessary to accurately grasp the time for winding the waste film, otherwise it is easy to cause the film to be broken. The servo motor can adjust the speed of the rotating shaft according to the needs of film cutting. Adjustment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com