Method for refining chlorogenic acid from honeysuckle crude extract

A technology for crude honeysuckle extract and honeysuckle extract, which is applied in the field of extracting chlorogenic acid and achieves the effects of large processing capacity, continuous and simple operation, and shortening of preparation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) D3520 type macroporous resin column impurity removal process

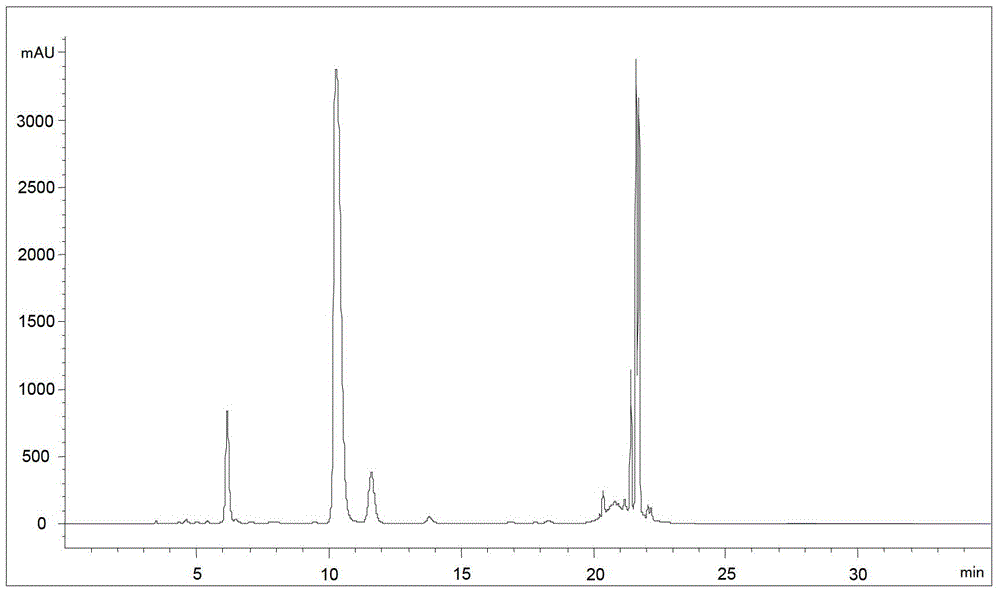

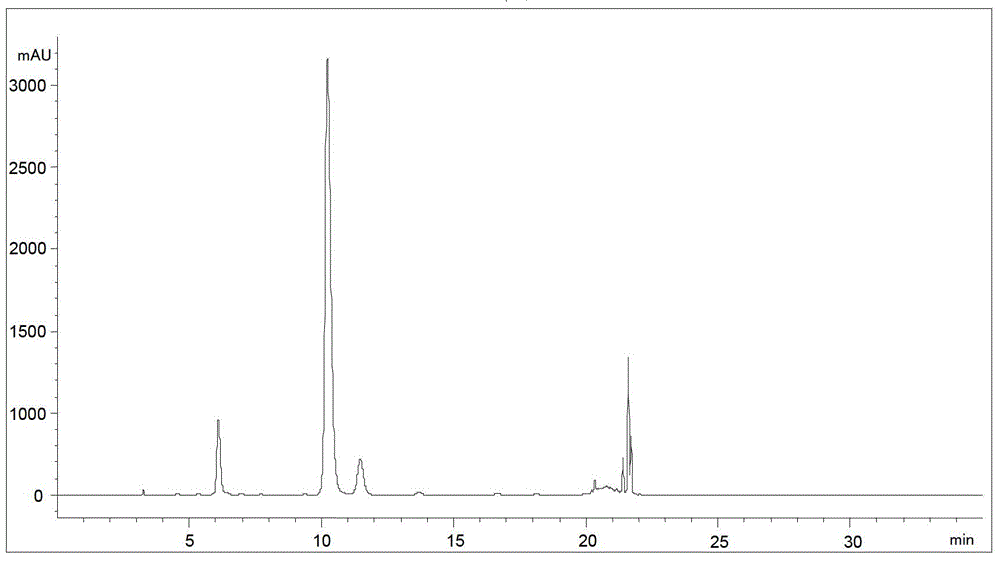

[0035] 100g of honeysuckle extract was dissolved in 1000mL deionized water, and after fully stirring, it was prepared into an aqueous solution of honeysuckle extract (the HPLC figure of chlorogenic acid in the aqueous solution is shown in figure 1 As shown), the above aqueous solution is passed through a D3520 macroporous resin column at a flow rate of 5BV / h to remove impurities such as flavonoids and sugars, and the effluent is collected. The HPLC diagram of chlorogenic acid in the effluent is shown in figure 2 shown.

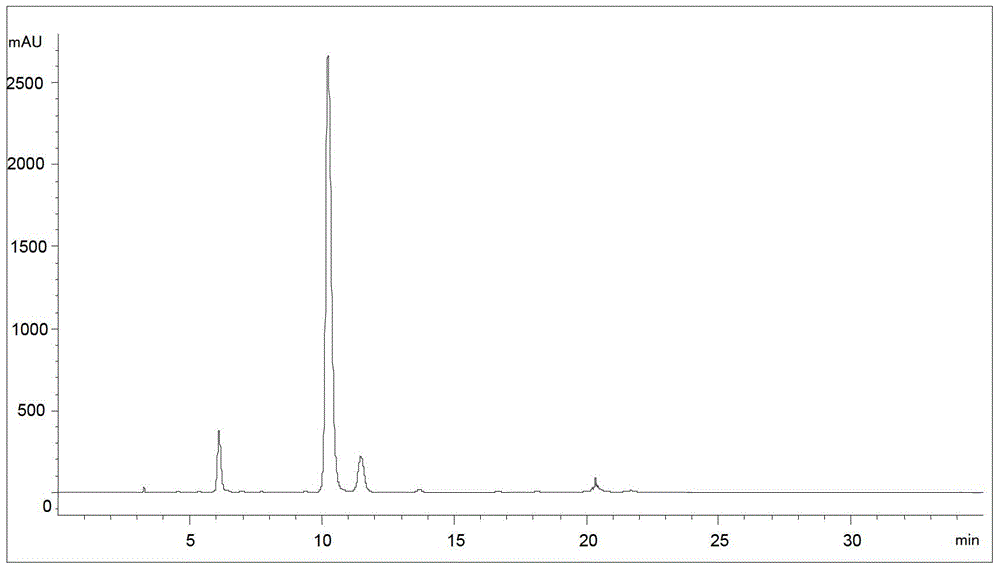

[0036] (2) ADS-F8 macroporous resin column enrichment and purification process

[0037] Pass the effluent collected in step (1) directly through the ADS-F8 macroporous resin column at a flow rate of 5BV / h. After the dynamic adsorption is saturated, rinse the above macroporous resin column with deionized water at a flow rate of 2BV / h until the The liquid is colorless, and then eluted w...

Embodiment 2

[0043] (1) D4006 type macroporous resin column impurity removal process

[0044] Dissolve 500g of honeysuckle extract with 5000mL of deionized water, and after fully stirring, prepare an aqueous solution of honeysuckle extract, pass the above aqueous solution through a D4006 macroporous resin column at a flow rate of 3BV / h to remove impurities such as flavonoids and sugars, and collect the effluent liquid.

[0045] (2) Enrichment and purification process of NKA macroporous resin column

[0046] Pass the effluent collected in step (1) directly through the NKA macroporous resin column at a flow rate of 3BV / h. After the dynamic adsorption is saturated, rinse the above macroporous resin column with deionized water at a flow rate of 4BV / h until the effluent color, and then eluted with 50% ethanol aqueous solution at a flow rate of 8BV / h, collected the eluate until no chlorogenic acid was detected by HPLC, and finally concentrated the collected eluate under reduced pressure to obta...

Embodiment 3

[0052] (1) H103 macroporous resin column impurity removal process

[0053]Dissolve 1000g of honeysuckle extract with 10000mL of deionized water, and after fully stirring, prepare an aqueous solution of honeysuckle extract, pass the above aqueous solution through a H103 macroporous resin column at a flow rate of 4BV / h to remove impurities such as flavonoids and sugars, and collect the effluent liquid.

[0054] (2) S-8 macroporous resin column enrichment and purification process

[0055] Pass the effluent collected in step (1) directly through the S-8 macroporous resin column at a flow rate of 4BV / h. After the dynamic adsorption is saturated, rinse the above macroporous resin column with deionized water at a flow rate of 6BV / h until the The liquid is colorless, and then eluted with 60% ethanol aqueous solution at a flow rate of 7BV / h, collects the eluate until no chlorogenic acid is detected by HPLC, and finally concentrates the collected eluate under reduced pressure to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com