A washing machine with the function of flocculating circulating water

A technology of washing machine and circulating water, which is applied in the field of washing machines, can solve the problems that washing water cannot be recycled and cannot be used, and achieve the effects of improving simple structure, reducing pollution, and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

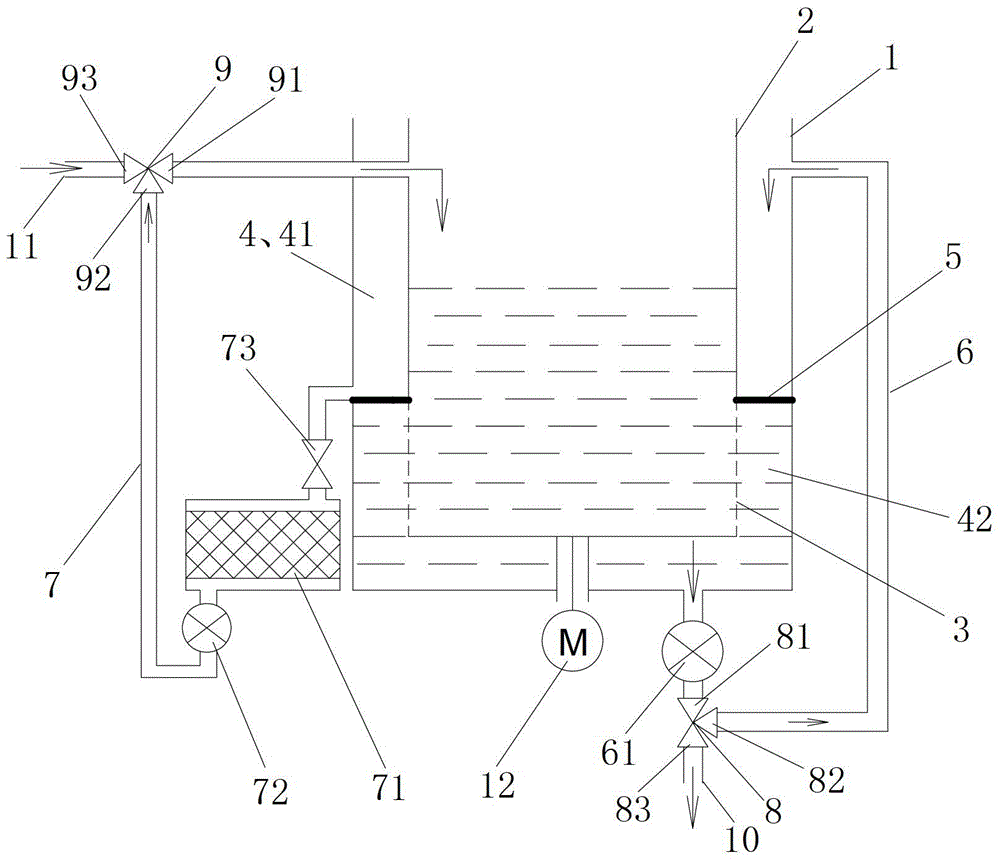

[0045] like figure 1 As shown, in this implementation, the chamber between the outer barrel 1 and the inner barrel 2 is isolated into a first sub-chamber 41 and a second sub-chamber 42 through the isolation layer 5, the isolation layer 5 is annular, Radial retractable sealing structure, dynamic seal between the isolation layer 5 and the inner barrel 2, divides the chamber between the outer barrel 1 and the inner barrel 2 into upper and lower parts, the upper part is the first sub-chamber 41, and the lower part is the first sub-chamber 41. Part of it is the second sub-chamber 42, the dehydration hole 3 is set on the inner barrel wall corresponding to the second sub-chamber 42, and the inner barrel wall corresponding to the first sub-chamber 41 is a sealed structure.

[0046] The horizontal position of the isolation layer 5 close to the flocculation outlet waterway 7 connected to it is lower than other positions, which is beneficial to the discharge of flocculation water. Part ...

Embodiment 2

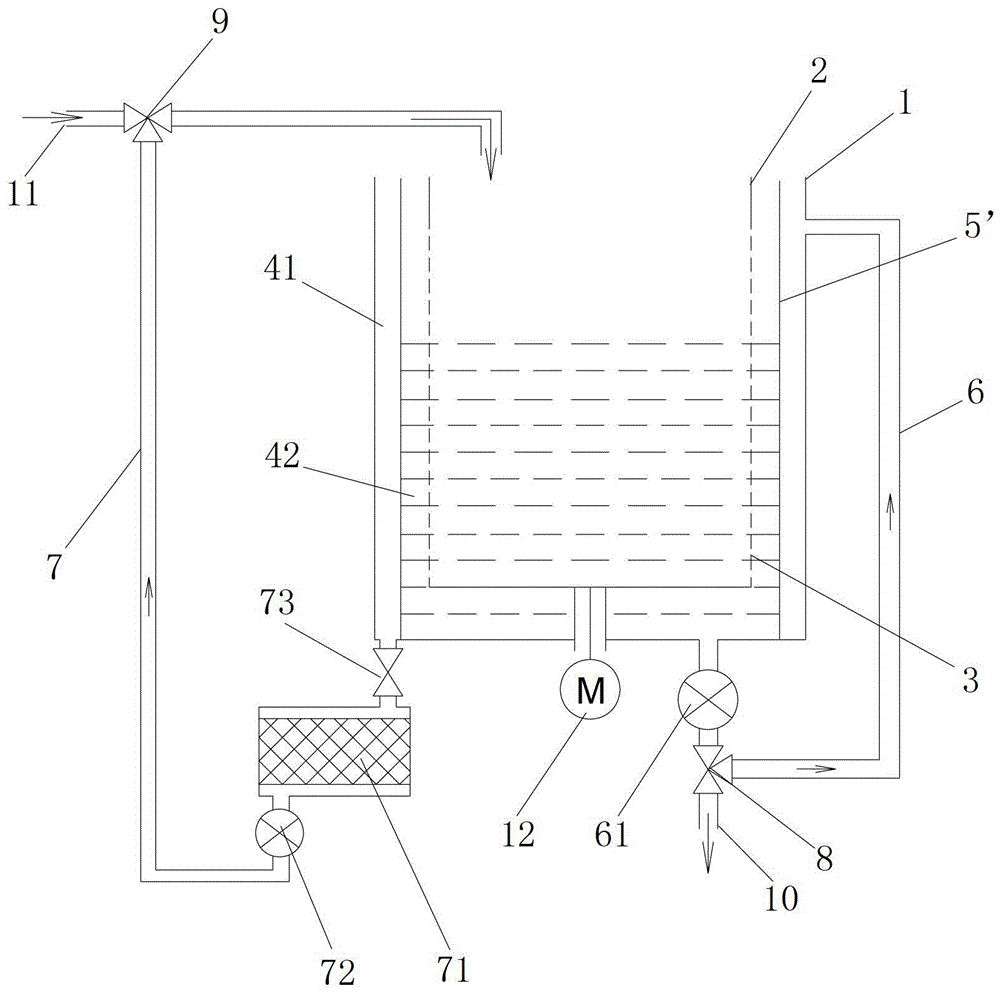

[0055] like figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the isolation layer 5' is a sleeve structure, the bottom end is sealed with the bottom of the outer barrel, the isolation layer 5' surrounds the outer periphery of the inner barrel 2, and the isolation layer 5' is connected to the outer barrel. The chamber between 1 is completely isolated from the inner barrel 2, and the chamber between the outer barrel 1 and the inner barrel 2 is divided into two parts, the inner ring and the outer ring. The outer ring part is the first sub-chamber 41, and the inner ring part is the second sub-chamber. subchamber 42 . This structure is equivalent to adding an intermediate barrel fixed in the outer barrel between the inner and outer barrels. The first sub-chamber is formed between the inner peripheral wall of the outer barrel and the outer peripheral wall of the middle barrel, and the second sub-chamber is formed between the inner peripheral wall of...

Embodiment 3

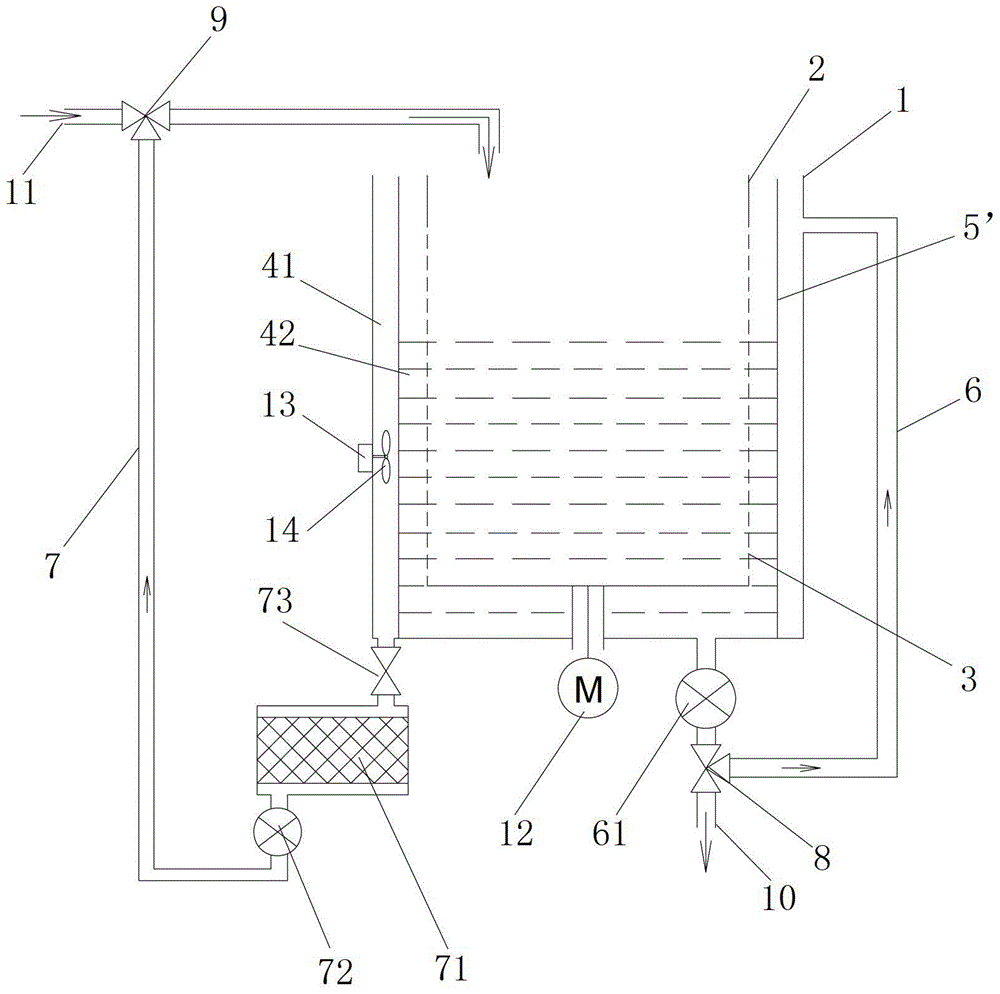

[0057] In this embodiment, on the basis of the above embodiments, a flocculation and stirring device is installed in the first sub-chamber. The device can be additionally provided with an independent drive, or utilize the vibration of the chamber between the inner and outer barrels when the inner barrel itself rotates during drainage and dehydration, or install the outer wall of the inner barrel to extend into the first sub-chamber and use the inner barrel to rotate and drive. In the first embodiment, the internal drum rotates to vibrate the chamber between the inner and outer drums during dehydration to realize agitation and dissolution of the flocculant; in the second embodiment, a drive motor 13 is installed outside the outer drum 1, and the drive shaft extends to the first sub-cavity Indoor driving stirring blade 14 rotates (referring to image 3 ), or, a stirring bar 15 extending into the first sub-chamber is installed on the outer wall of the inner barrel 2, and the stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com