T-shaped double-seal leakage stopping clamp for pipeline and processing method

A double-sealing, pipeline technology, applied in the direction of pipe components, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of high installation procedures and requirements, difficult installation requirements, limited applicability, etc., to achieve high reliability requirements, The effect of fast plugging speed and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

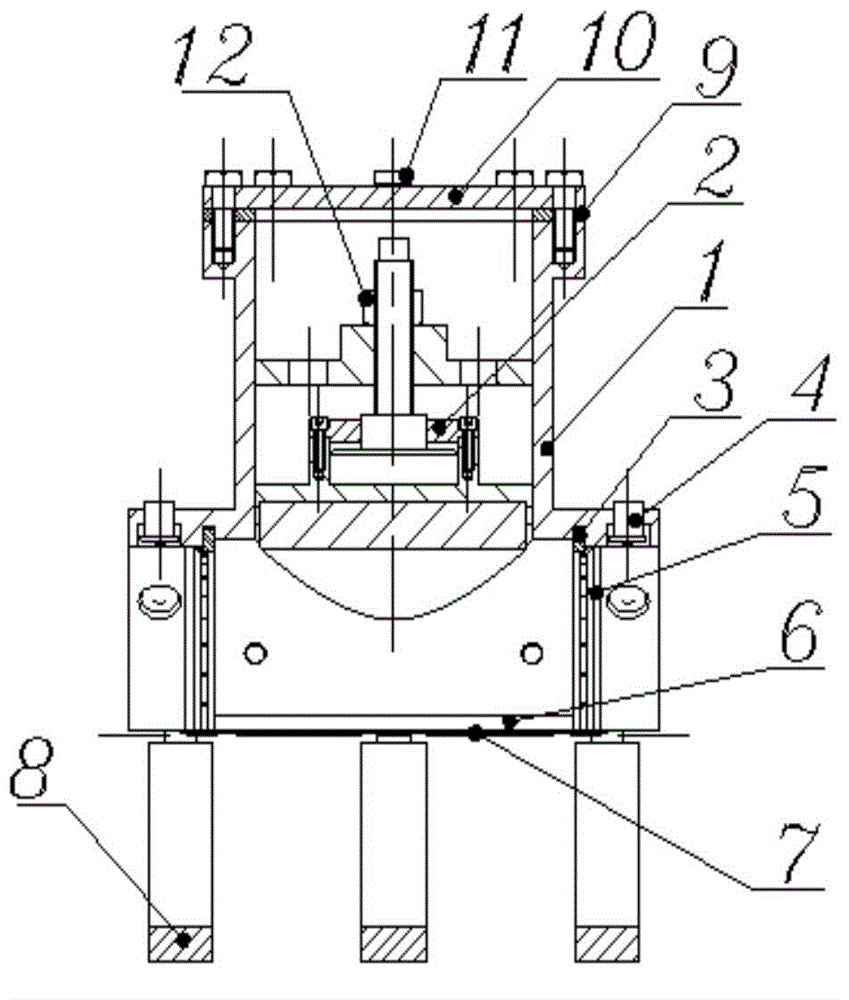

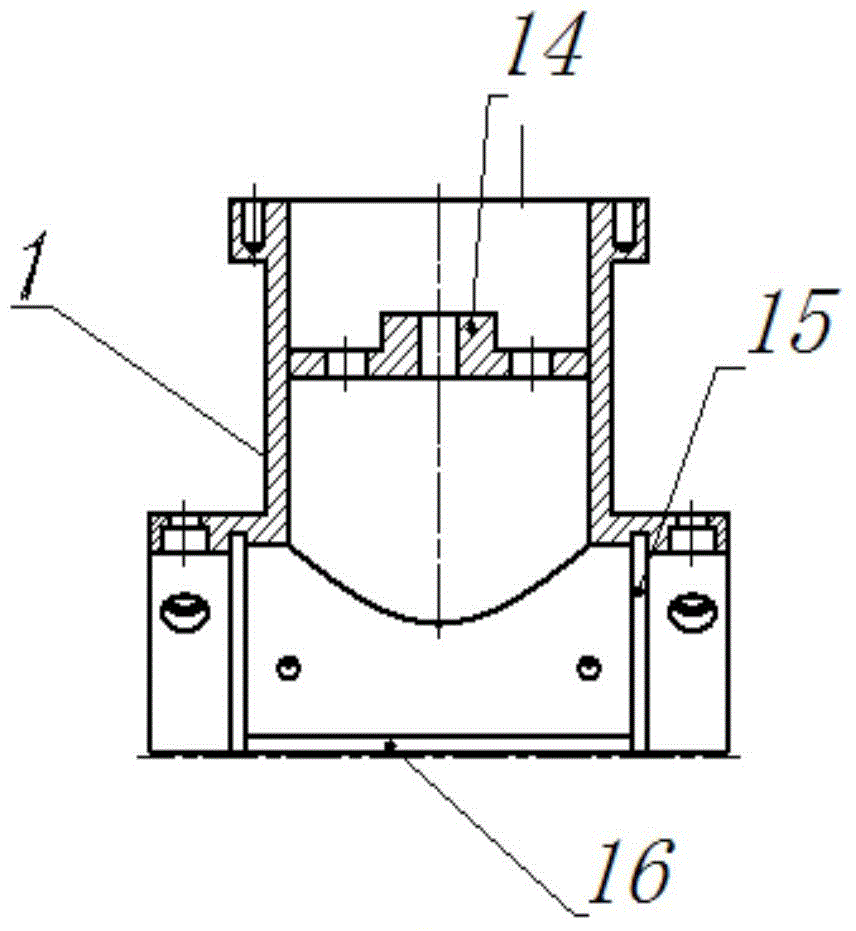

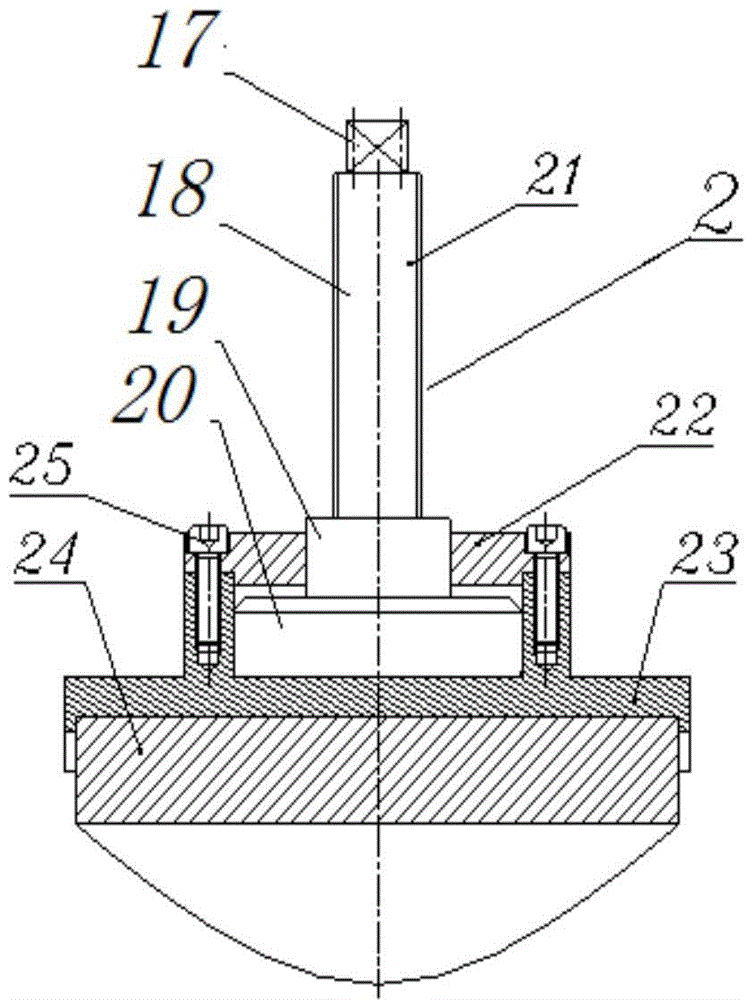

[0021] Example 1: as figure 1 , figure 2 , image 3 , Figure 4 As shown in the figure, a T-shaped double-sealing pipeline leakage plugging fixture is composed of a T-shaped clamping body 1, a top pressure sealing assembly 2, a circumferential sealing strip 3, a spring-loaded universal ball 4, a circumferential sealing pressure plate 5, an axial seal Strip 6, axial sealing pressure plate 7, clamp 8, top cover gasket 9, top cover 10, top cover fastening bolt 11, locking nut 12, and half-clamp fastening bolt assembly 13.

[0022] The structure and characteristics of the T-shaped clamp body 1 are: the T-shaped clamp body 1 is an intersecting body that is vertically intersected by a semicircular tube shell with lugs and a riser with a flange on the top; There are 3 countersunk holes for installing the spring universal ball 4, and there are 2 circumferential sealing strip installation grooves 15 and 2 axial sealing strip installation grooves 16 on the inner wall of the semi-cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com