Liquefied natural gas twin-pump gas station

A technology of liquefied natural gas and gas filling stations, which is applied in the direction of gas/liquid distribution and storage, equipment loaded into pressure vessels, and methods of container discharge. Simultaneous flow of liquid, LNG stratification and tumbling danger, etc., to eliminate the phenomenon of stratification and tumbling, facilitate automatic control, and have good cold preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0076] Example 1: There is no LNG liquid in the storage tank 41, but there is LNG liquid in the storage tank 42.

[0077] A pump 45 starts the unloading process to fill a storage tank 41 with liquid, and a pump 46 starts the liquid filling process to use the LNG in the other storage tank 42 to add liquid to the outside through the gas dispenser, and they are carried out simultaneously;

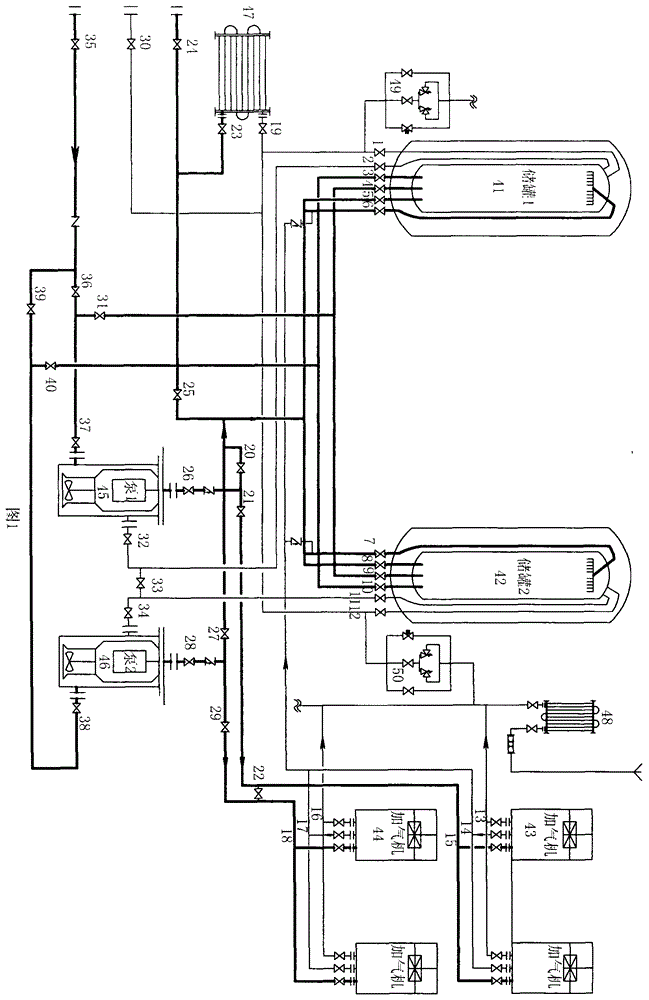

[0078] figure 1 Indicates the LNG double-pump filling station:

[0079] exist figure 1 middle,

[0080] There is no LNG liquid in the storage tank 41, and there is LNG liquid in the storage tank 42. Add liquid to the storage tank 41. Obviously, there is no LNG layering and rolling phenomenon in the storage tank 41. The two tanks are used separately, and recycling is a technical feature of this case. , which cannot be achieved by existing technologies. This is a very large technological advance that is not obvious from the existing technology.

[0081] Use the pump 45 to unload the liquid ...

example 2

[0085] Example 2: Two pumps correspond to one storage tank 42 at the same time, and the LNG in the storage tank is used up as soon as possible.

[0086] figure 1 Indicates the LNG double-pump filling station:

[0087] exist figure 1 middle,

[0088] Above-mentioned example one, storage tank 41 is filled with LNG, and this liquid is cold liquid, and pressure is low, can store several days, now concentrates two pumps to use up LNG in the storage tank 42 for external addition.

[0089] Close valves 1, 2, 3, 4, 5, and 6 under the storage tank 41;

[0090] Open two pumps 45,46 air return port valves and the gas phase valve of storage tank 42 i.e. 32,33,34,11;

[0091] Open the liquid outlet valve 9 of the storage tank 42 and enter the pump 45 through the opening of the valves 31 and 37, the pump 45 is started, the valve 20 is closed, the valves 26 and 21 are opened, and the liquid enters the gas dispenser through the valve 15 to add liquid;

[0092] Open the liquid outlet valv...

example 3

[0095] Example three, when the LNG liquid in the storage tank 42 is used up, repeat the action of example one, that is, one pump 46 starts the unloading process to fill a storage tank 42 with liquid, and one pump 45 starts the liquid addition process to use the LNG in another storage tank 41 The liquid is added to the outside through the gas dispenser, and they are carried out at the same time;

[0096] Similar to the action in Example 1, adjust the opening and closing of the pump and storage tank valve accordingly, which is omitted here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com