Drawing and inserting type heat-resistant and wear-resistant ceramic preheater inner tube

A technology of wear-resistant ceramics and preheaters, which can be used in preheating costs, lighting and heating equipment, furnaces, etc. It can solve the problems of poor high temperature thermal shock resistance and easy fracture, poor high temperature strength and falling off of ordinary refractory materials, and achieve high temperature Impact resistance is not easy to break, reduces equipment maintenance costs, and has good impact resistance at high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further illustrate the present invention, further describe below in conjunction with accompanying drawing:

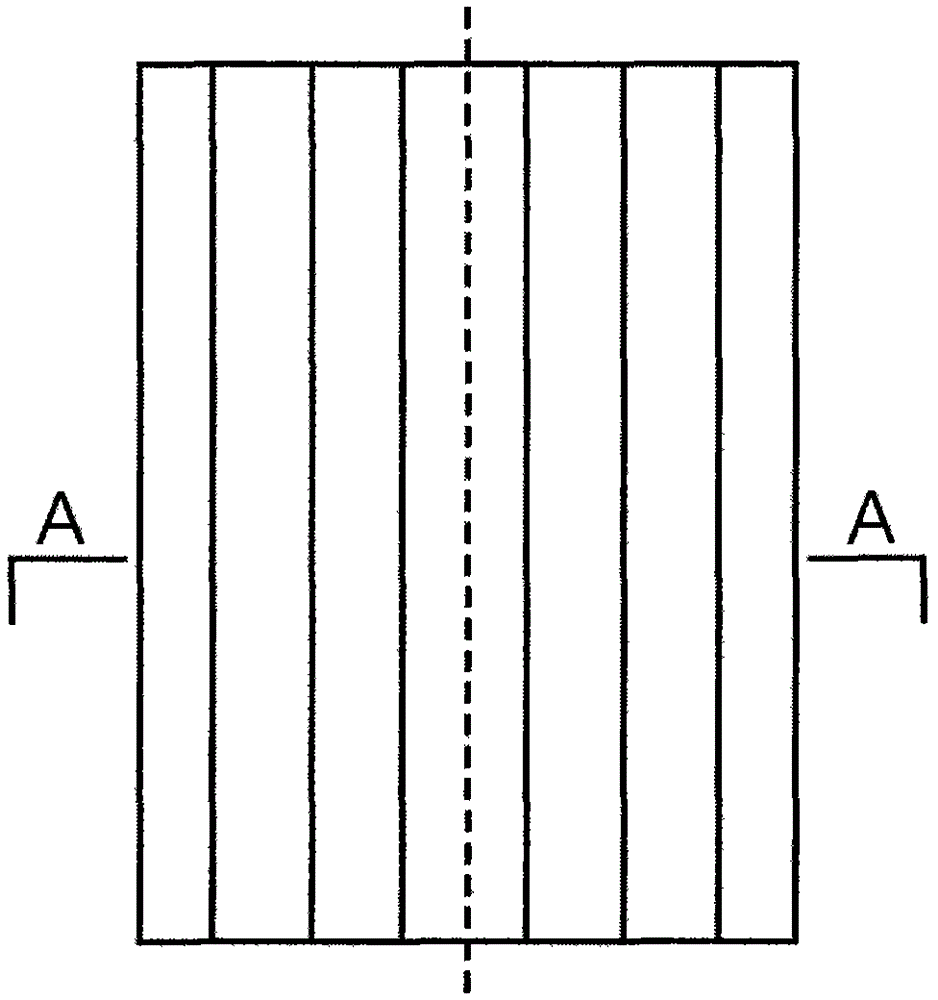

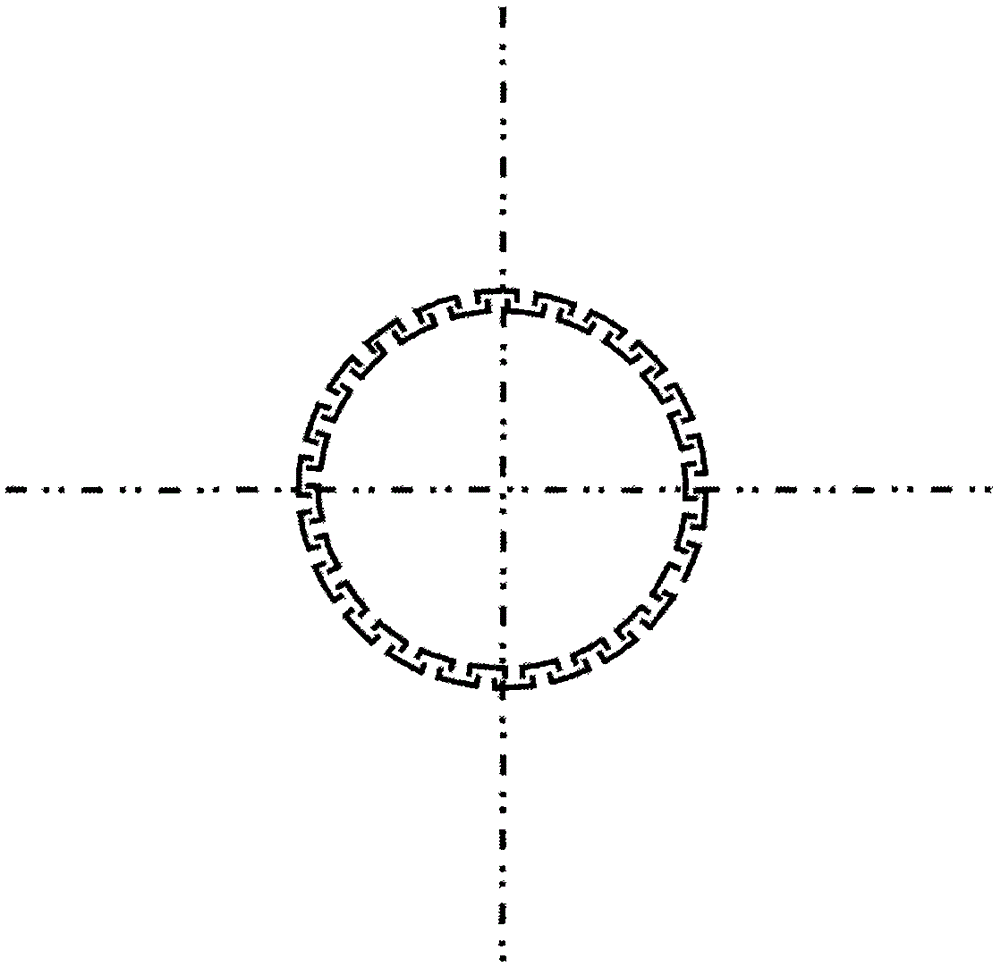

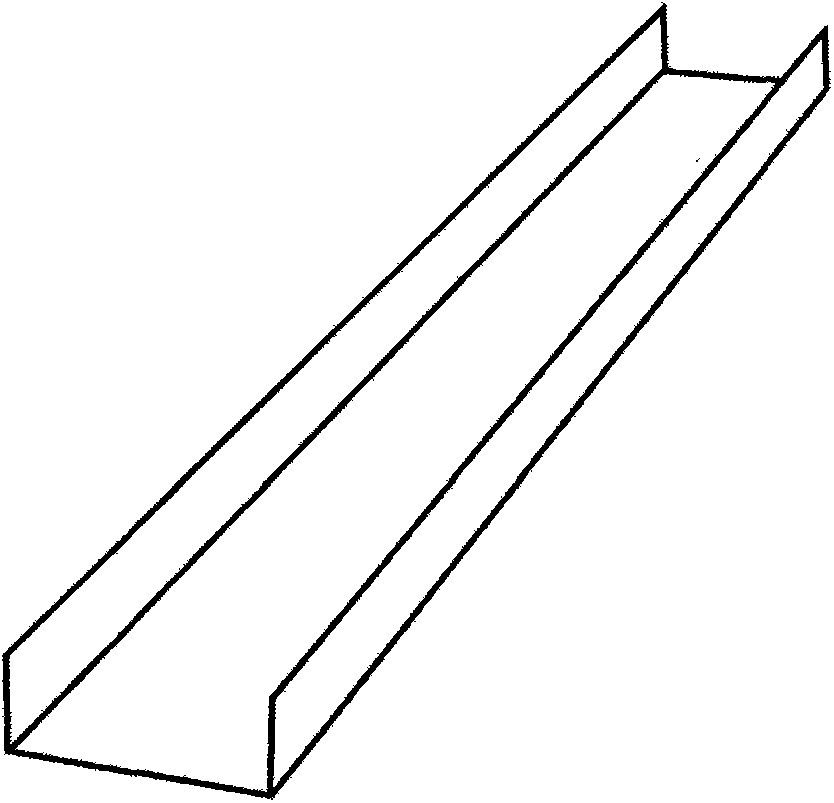

[0018] Such as figure 1 , figure 2 and image 3 As shown, a plug-in heat-resistant and wear-resistant ceramic preheater inner cylinder of the present invention selects a low-cost wear-resistant structural ceramic material, processes the structural ceramic material into a U-shaped groove plate, and then the U-shaped groove One end of the plate is placed outside the working room as the installation end, and the other end is inserted into the preheater through the preset jack, and each U-shaped groove plate is reversely connected to form a cylinder. During the production process, when a U-shaped groove plate is accidentally damaged, it can be easily pulled out without stopping the kiln, and then inserted and replaced with a new part of the same material. The invention has a simple structure and does not affect the continuity and stability of producti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com