Methane storing type glass microsphere sensitized emulsion explosive and preparation method

A technology of glass microspheres and emulsion explosives, which is applied in explosives, non-explosive/non-thermal agent components, offensive equipment, etc., can solve the problems of explosive power to be improved, insufficient energy output of emulsion explosives, etc., and achieve explosive energy and explosive gas products The effects of superior content, improved power and working ability, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further illustrated below by way of examples. The embodiments of the present invention are only used to illustrate the present invention, but not to limit the present invention.

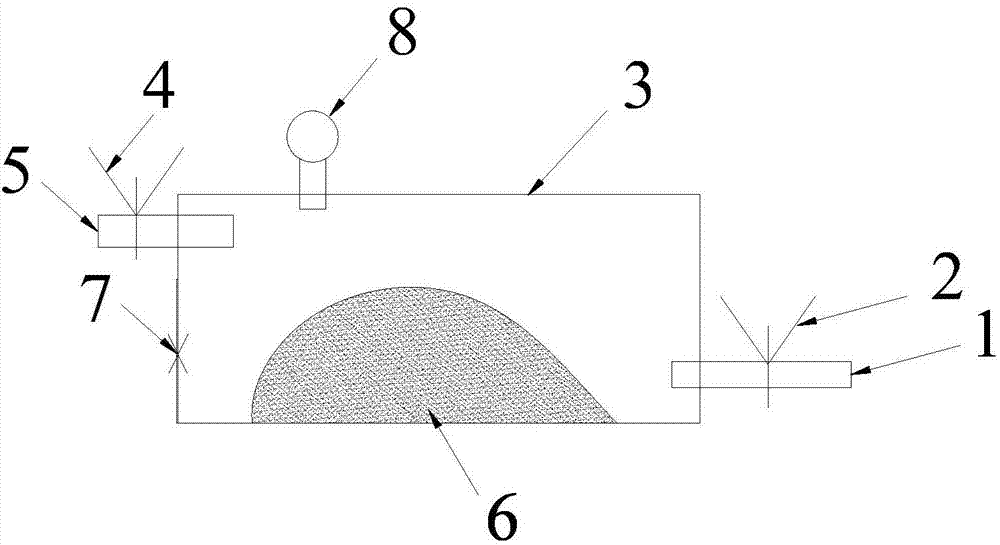

[0018] When preparing methane-storing glass microsphere sensitized emulsion explosives, first, according to figure 1 The continuous ventilation device shown in the figure produces methane-storage glass microspheres. The specific steps are: 1. Open the inlet and outlet 7, put the glass microspheres into the continuous ventilation main body 3, close the inlet and outlet 7, and turn off the exhaust switch 2. Open the intake switch 4, fill the continuous ventilation body 3 with methane gas through the intake pipe 5, until the pressure is 3MPa, close the intake switch 4, open the exhaust switch 2, and discharge the methane air mixture through the exhaust pipe 1 Gas, the pressure at the exhaust pipe 1 is normal pressure, the exhaust pipe 1 can be connected to the exhaust ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com