Hybrid heating method adopting skirt membrane type spray pipe

A heating method and nozzle technology, applied in lighting and heating equipment, direct contact heat exchangers, heat exchanger types, etc., can solve the problems of long heating process, uneven heating, large heat loss, etc. Quick exchange, uniform heat exchange, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

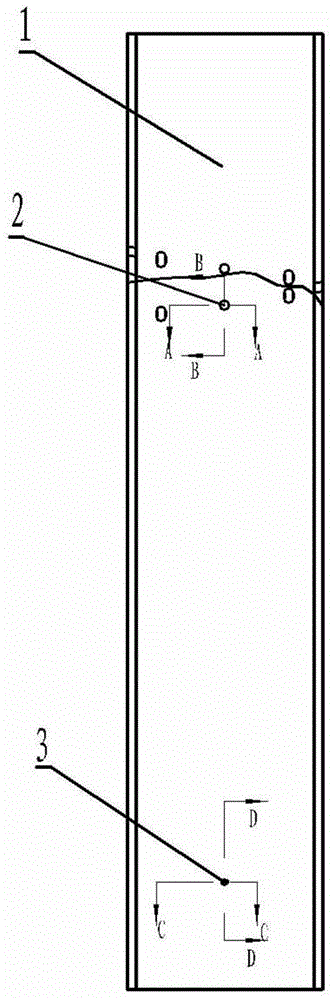

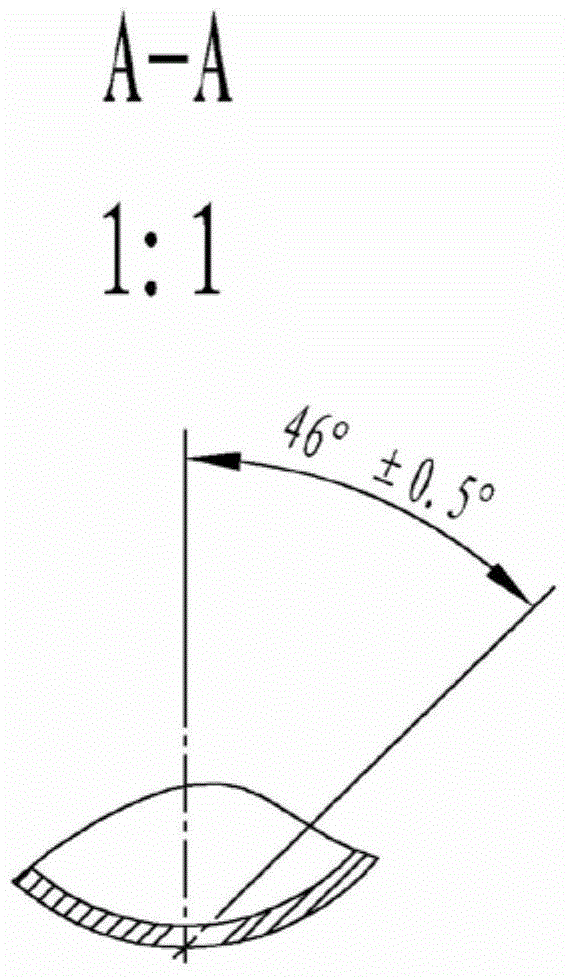

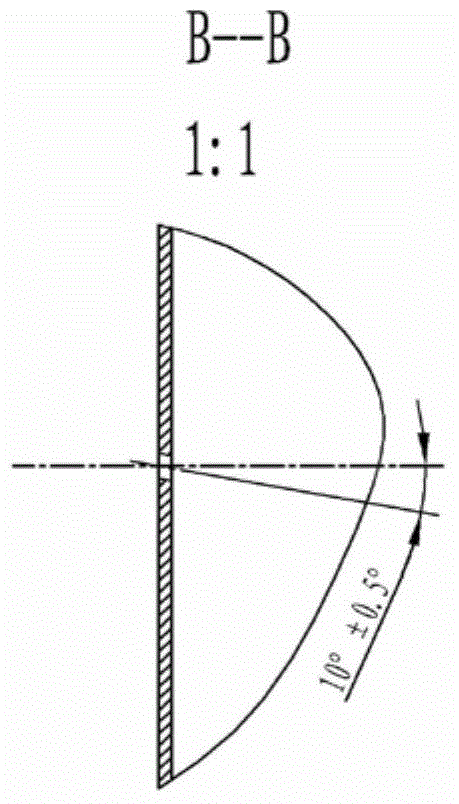

[0012] Such as figure 1 and figure 2 , image 3 , Figure 4 , Figure 5 As shown, a skirt film type nozzle mixed heating method, in order to realize this method, the components include a hole tube body 1, a main space hole 2, and an auxiliary space hole 3, and the upper part of the tube body of the hole tube body 1 is arranged according to the helical direction The main space hole 2 forms the main space hole group, and the auxiliary space hole 3 at the lower symmetrical position of the pipe body of the orifice body 1 forms the auxiliary space hole group, and the opening orientation of each main space hole 2 forming the main space hole group is the spatial orientation, The orifice tube body 1 starts from the upper part downwards at 25% of the overall length, and there are eight main space holes 2 that are evenly distributed according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com