Heat conductor with ultra-thin flat plate type capillary structure

A technology of capillary structure and flat plate shape, which is applied in the field of heat conductors with ultra-thin flat capillary structure, which can solve the problems of large resistance of metal powder, inability to maintain steam channels, and inability of heat pipes to form air flow channels, etc., to achieve small contact thermal resistance , the effect of large capillary surface area and truncated transmission surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

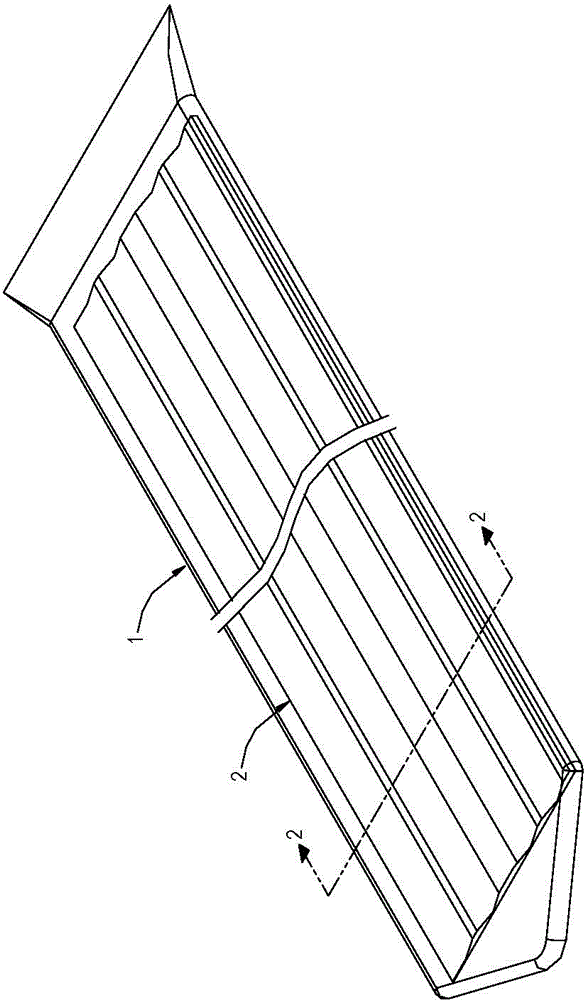

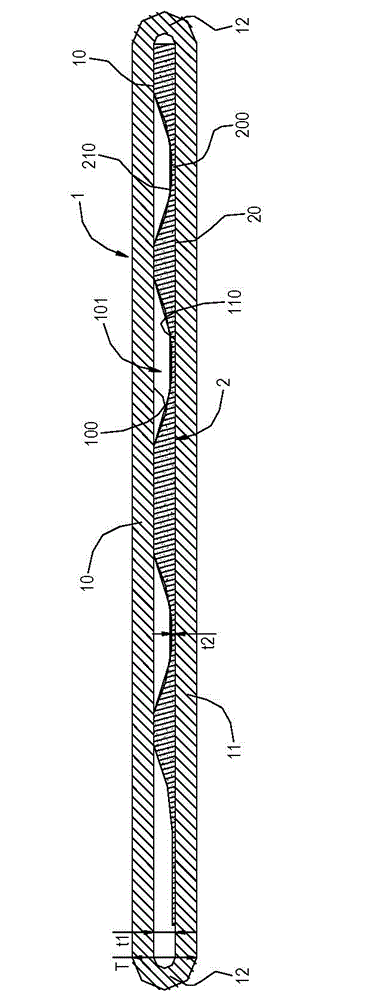

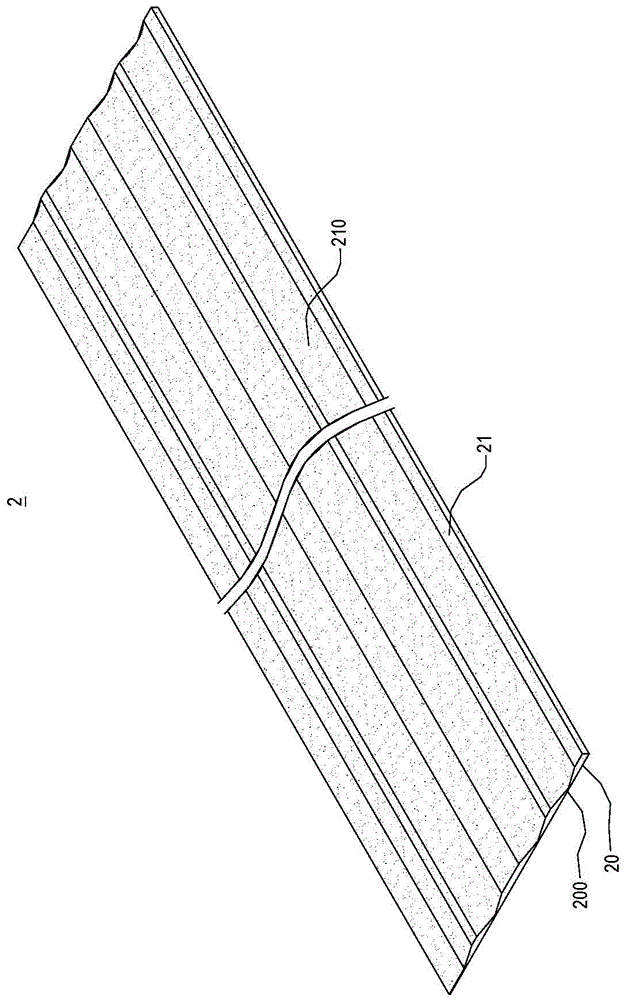

[0040] see figure 1 , is a schematic diagram of the three-dimensional appearance of the present invention. The present invention provides a heat conductor with an ultra-thin planar capillary structure, which includes a planar hollow shell 1 and at least one capillary structure 2 arranged in the shell 1 and in contact with its inner wall; wherein :

[0041] Such as figure 1 and figure 2 As shown, the shell 1 can be formed into the flat plate shape through processes such as flattening, and the thickness T of its outer contour can be pressed below 0.5 mm. And in the embodiment of the present invention, the housing 1 has an upper wall 10 and a lower wall 11 opposite to each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com