Elevating mechanism for stereo image laser printing machine

A lifting mechanism and stereoscopic image technology, applied in optics, printing equipment, printing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

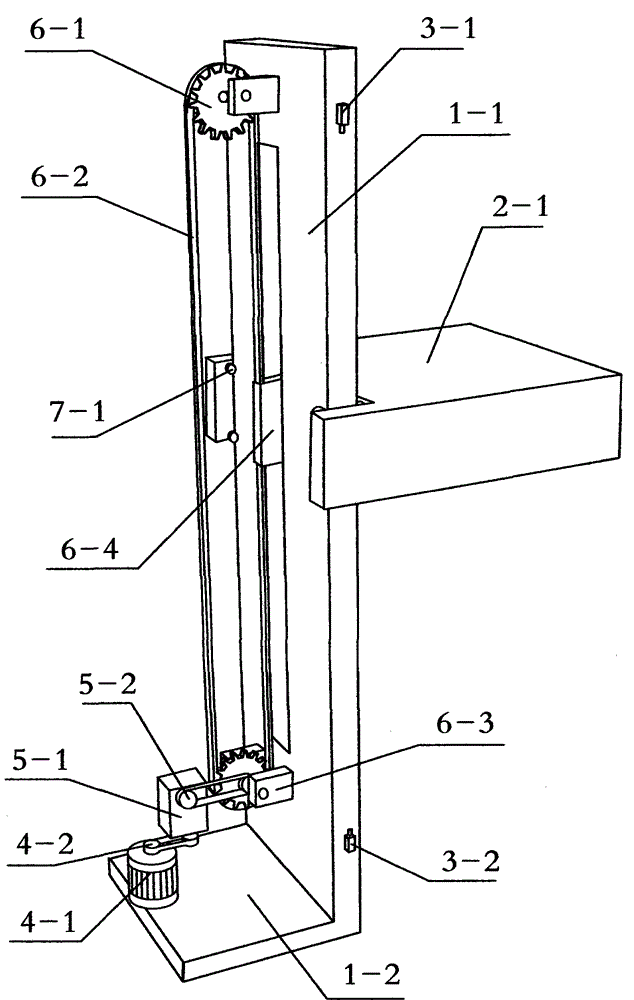

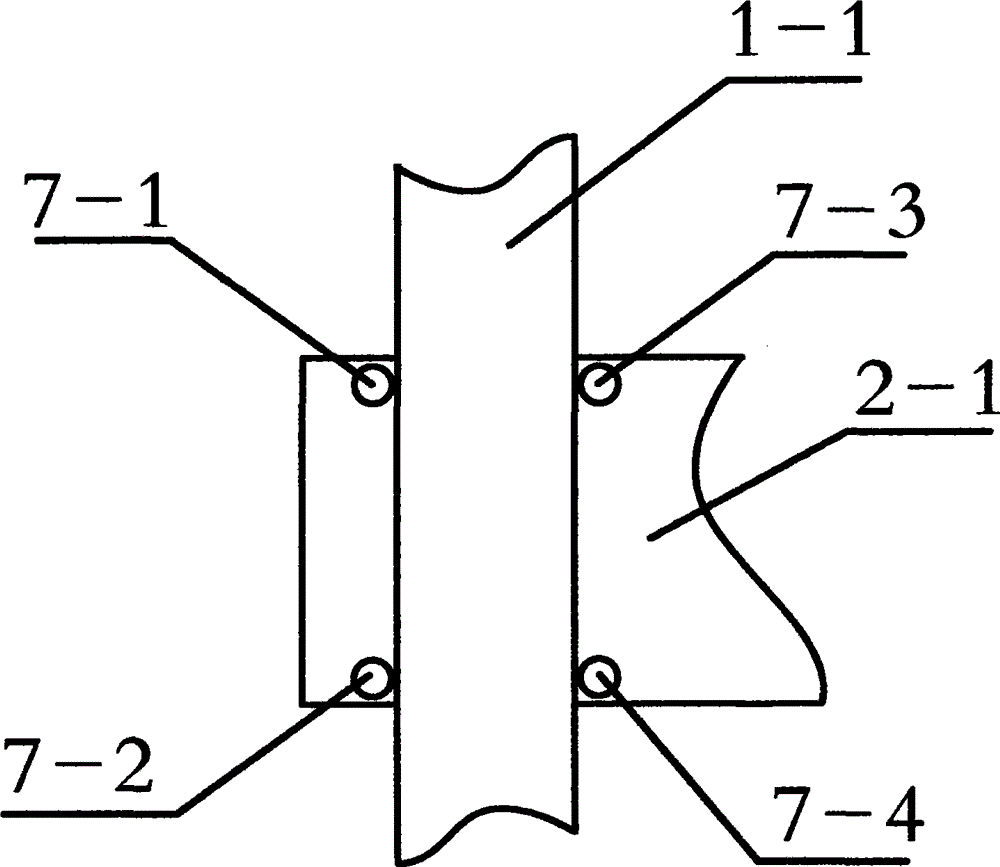

[0017] Such as figure 2 As shown, a lifting mechanism of a three-dimensional image laser printing machine of the present invention includes a vertical linear track 1-1, a stepping motor 4-1 for output power, a deceleration and self-locking device worm gear reducer 5-1, and a traction laser The sprocket chain device 6-1 that moves up and down the film clamp platform 2-1, the stroke switch device 3-1, 3-2 that controls the movement limit of the laser film clamp platform, and the roller device 7 installed on the laser film clamp platform 2-1 -1, the sprocket chain device 6-1 is dragged and connected to the laser film holder platform 2-1 through the coupling block 6-4. During operation, jog the start switch of the stepping motor 4-1, drive the motor pulley device 4-2, and transmit the power to the worm gear reducer 5-1, after being decelerated by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com