Light-emitting diode unit and light-emitting device

A technology for light-emitting diodes and light-emitting devices, which is applied to electrical components, electrical solid-state devices, circuits, etc., can solve the problems of increasing the electrode area, reducing the light-emitting area of the light-emitting diode die, and complicated circuit configuration steps of the light-emitting diode die array. The effect of reducing the electrode area and increasing the effective light-emitting area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

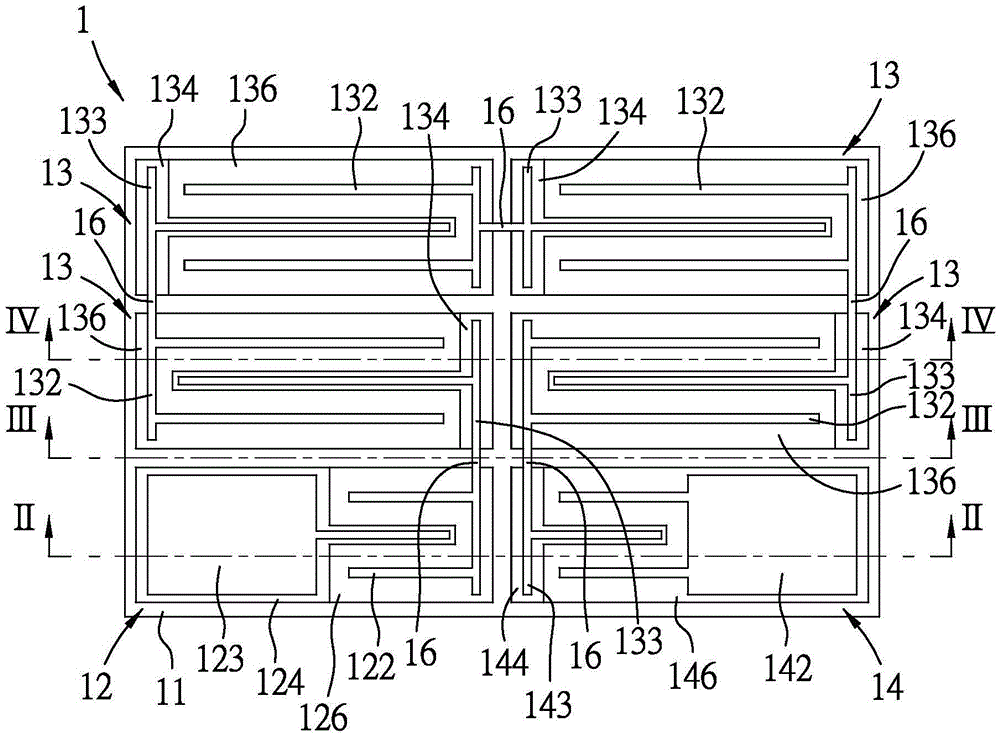

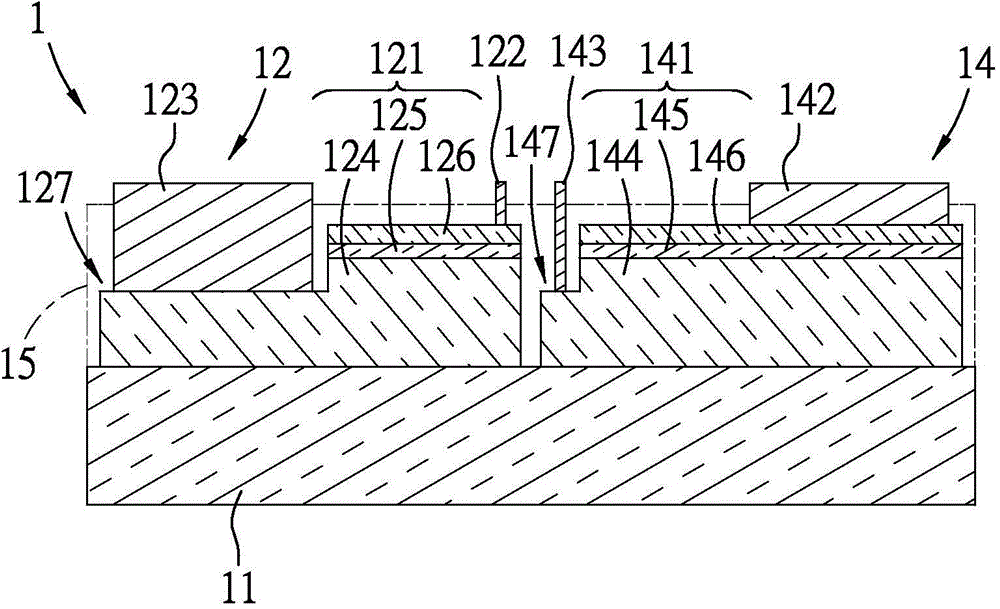

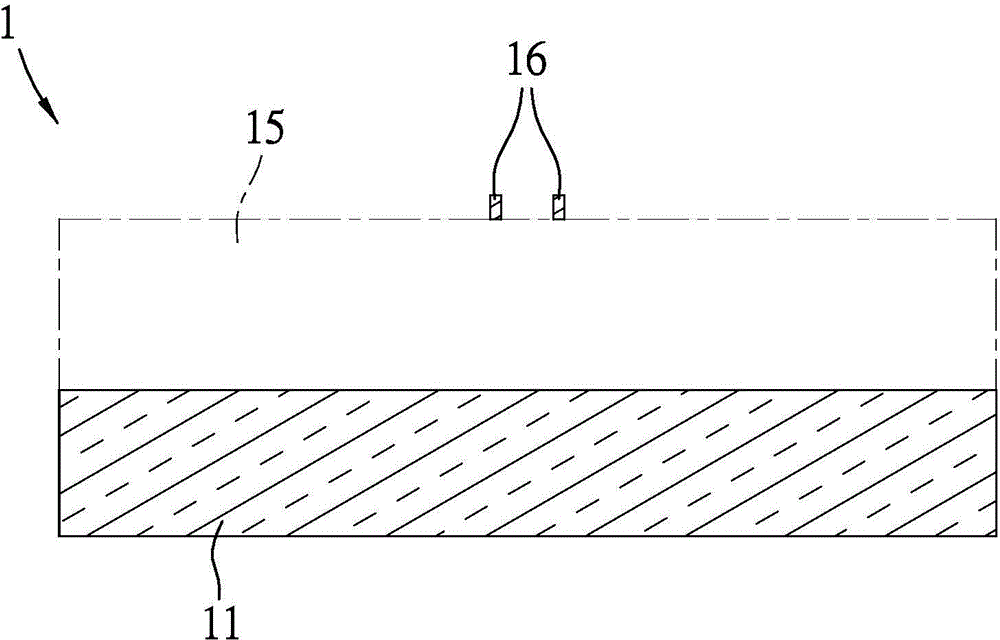

[0047] refer to Figure 1 to Figure 4 , is the first preferred embodiment of the LED unit 1 of the present invention. In this embodiment, the LED unit 1 adopts LED chip array technology, contains multiple LED chips, and can be integrated and used as a single light source.

[0048] Specifically, in the first embodiment, the LED unit 1 can radiate light in all directions, and includes a light-transmissible substrate 11, a first grain structure 12, at least one second grain structure 13, a first Three grain structures 14 , a first insulating structure 15 and a plurality of connecting portions 16 . Hereinafter, it is assumed that the light-emitting diode unit 1 can emit blue light, so its material is described with a blue light-emitting diode as an example, but the structure, material and emission color of the light-emitting diode unit 1 can be adjusted as required, for example, gallium arsenide (GaAs ), gallium arsenide phosphide (GaAsP), gallium arsenide arsenide (GaAlAs), gal...

no. 2 example

[0073] refer to figure 2 , Figure 10 , Figure 11 and Figure 12 , is the second preferred embodiment of the LED unit 1 of the present invention. in, figure 2 , Figure 11 and Figure 12 respectively Figure 10 Schematic cross-sectional view of the II-II line, the XI-XI line and the XII-XII line. Here, the light emitting diode unit 1 is different from the first embodiment in that it is a single-side light-emitting light source, and its light irradiation is generally caused by the light generated by the light-emitting diode crystal grains passing through the substrate 11, which is visually similar to that from the bottom surface of the substrate 11. To emit light, and compared with the first preferred embodiment, the light emitting diode unit 1 further includes a second insulating structure 17 and a light reflecting structure 18 .

[0074] Specifically, in this embodiment, the second insulating structure 17 is light-transmitting and covers at least the surface of the...

no. 3 example

[0077] refer to Figure 13 to Figure 16 , is the third preferred embodiment of the LED unit 1 of the present invention. Here, the light-emitting diode unit 1 is also used as a single-sided light-emitting light source, but the direction of light irradiation is opposite to that of the second embodiment, mainly emitting light from the die side. In terms of structure, compared with the first embodiment, the light emitting diode unit 1 of the third embodiment further includes a structure disposed on the substrate 11 opposite to the first grain structure 12, the second grain structure 13 and the third grain structure 14 The light reflective structure 18 on the other side, the light reflective structure 18 may be the aforementioned metal reflective structure or Bragg reflective structure. Accordingly, after the light emitted by the first grain structure 12, the second grain structure 13 and the third grain structure 14 is reflected by the reflective structure 18, it will be irradiat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com