Method for ultra-high-frequency measurement of partial discharge, and related device

A partial discharge and ultra-high frequency technology, applied in the field of supporting parts for maintaining ultra-high frequency sensors, can solve the problems of UHF signal deformation and attenuation, and achieve the effect of easy maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

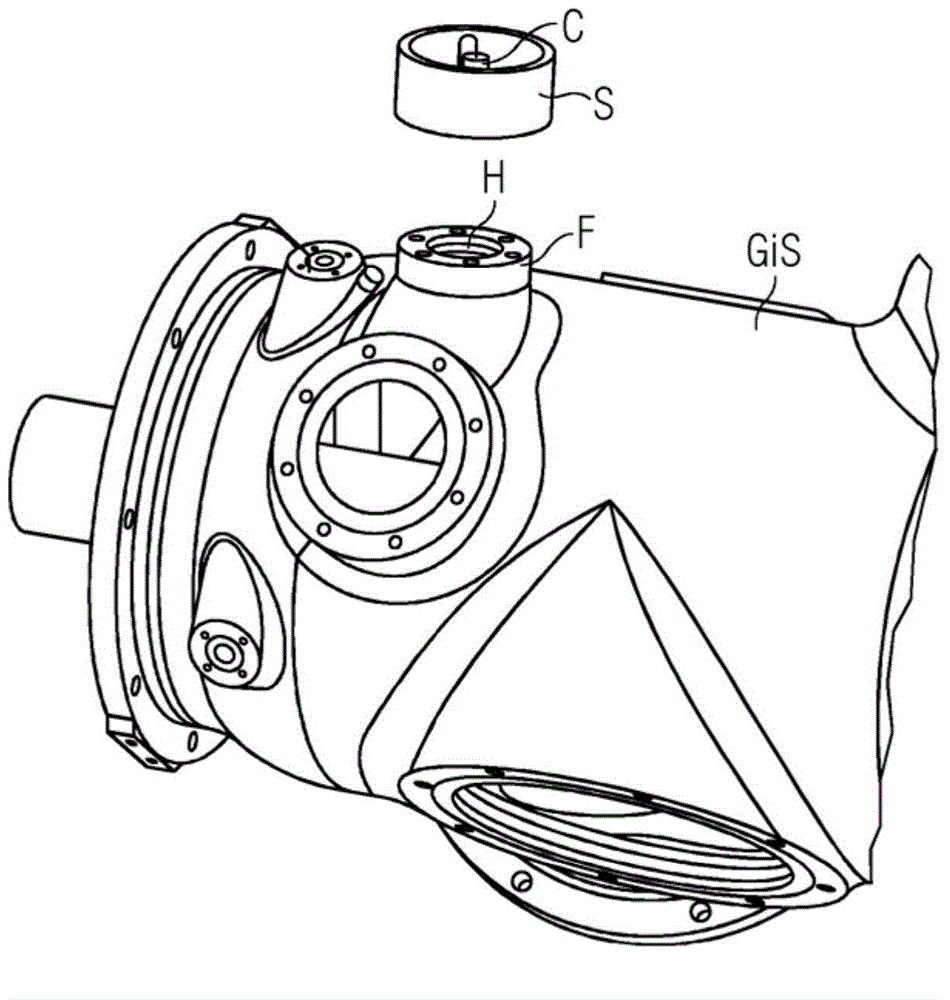

[0018] figure 1 Shows a general view of the compartment of the enclosure of the substation (GIS) under the metal enclosure, where the front holding support S for the UHF sensor C is in contact with the window H provided on the wall of the GIS substation. The window H, made of safety glass and having a circular shape, is here fixed rigidly to the casing of the GIS substation by means of a fixing ring F, which is usually screwed into a thread in the casing of the GIS substation.

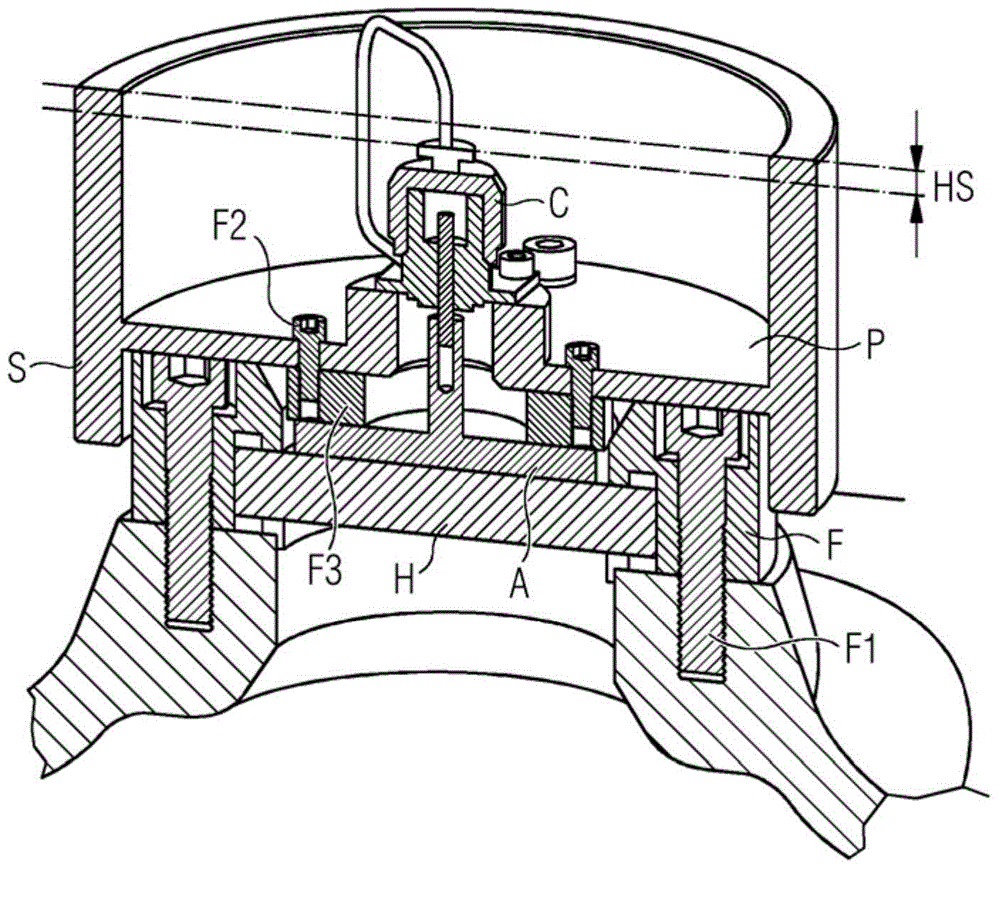

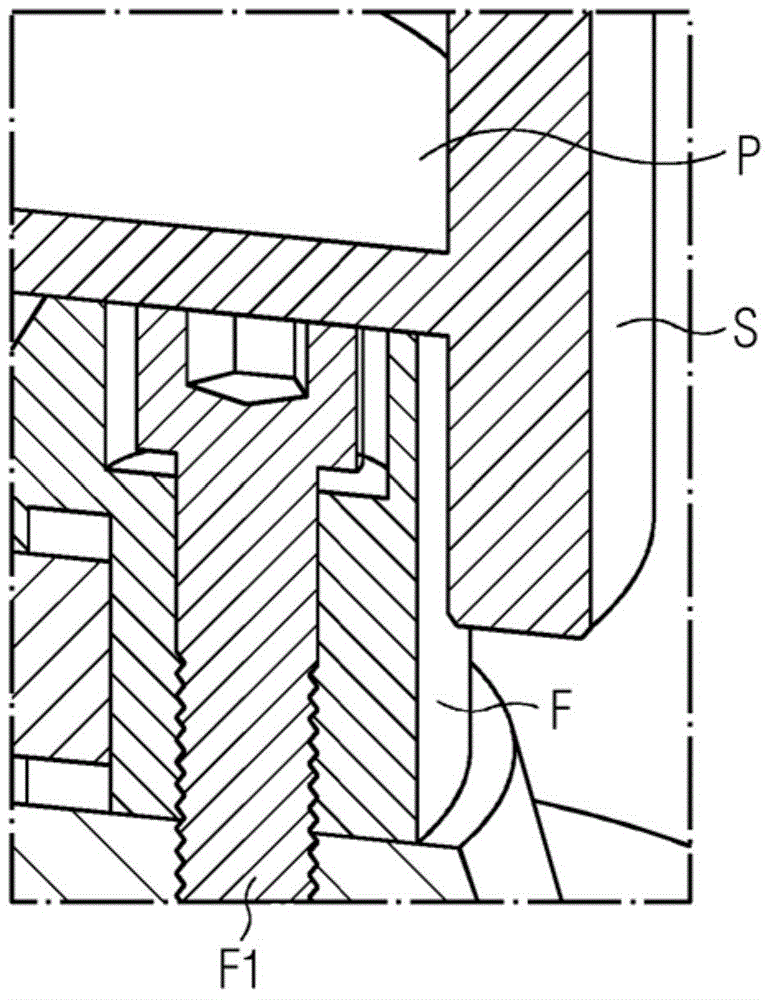

[0019] figure 2 show the basis figure 1 A diametrical cross-sectional view of the holding support S and the sensor C after the sensor C is in contact with the outer surface of the window H. The retaining support, having a tubular shape to slide around the fixing ring F, consists essentially of two tubular notches separated by a plate P. A first notch located under the plate covers the fixing ring F and the outer part of the window. The sensor C is rigidly fixed (in the direction of the part to whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com