Shear-fork type variable-pitch mechanical arm

A manipulator and scissor technology, which is applied in the field of scissor-type variable-distance bowl-shifting manipulator, can solve the problems of high cost, slow speed, and difficulty in keeping up with the pace of modernization, and achieves strong practicability, simple structure, and convenient production and use. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

[0021] The technical scheme that the present invention adopts is as follows

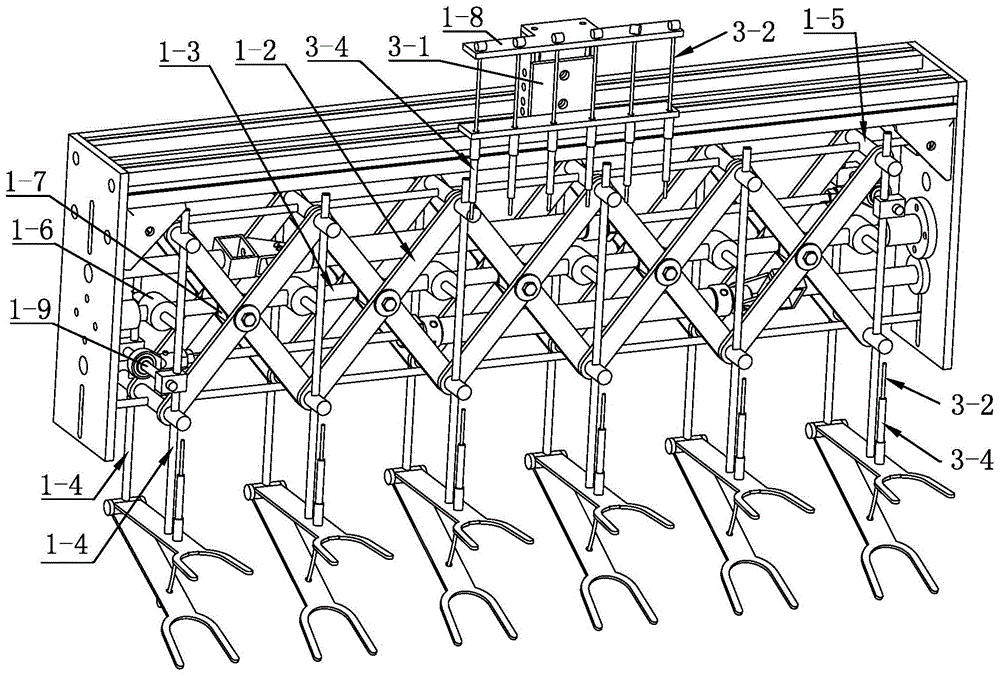

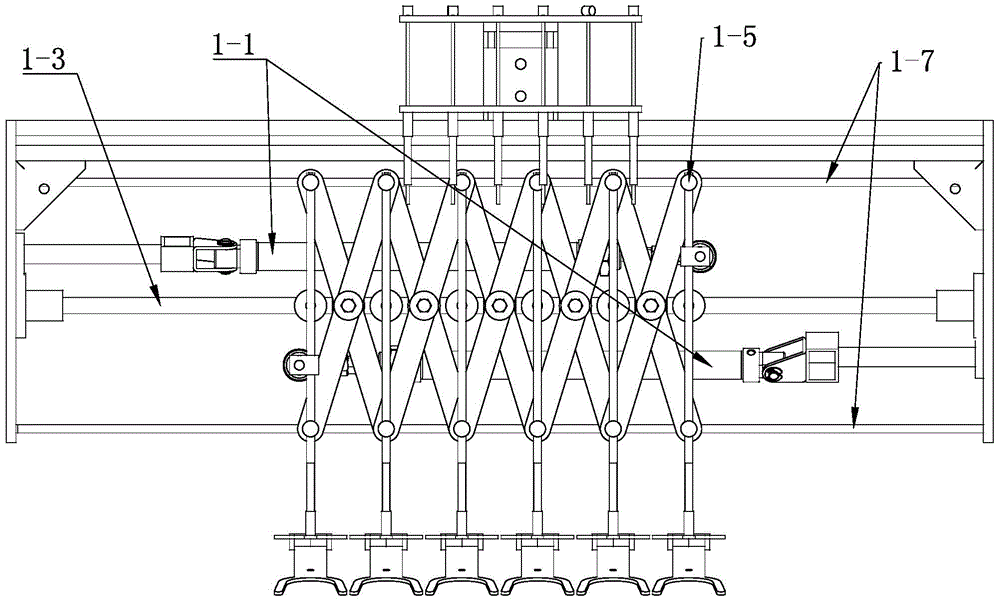

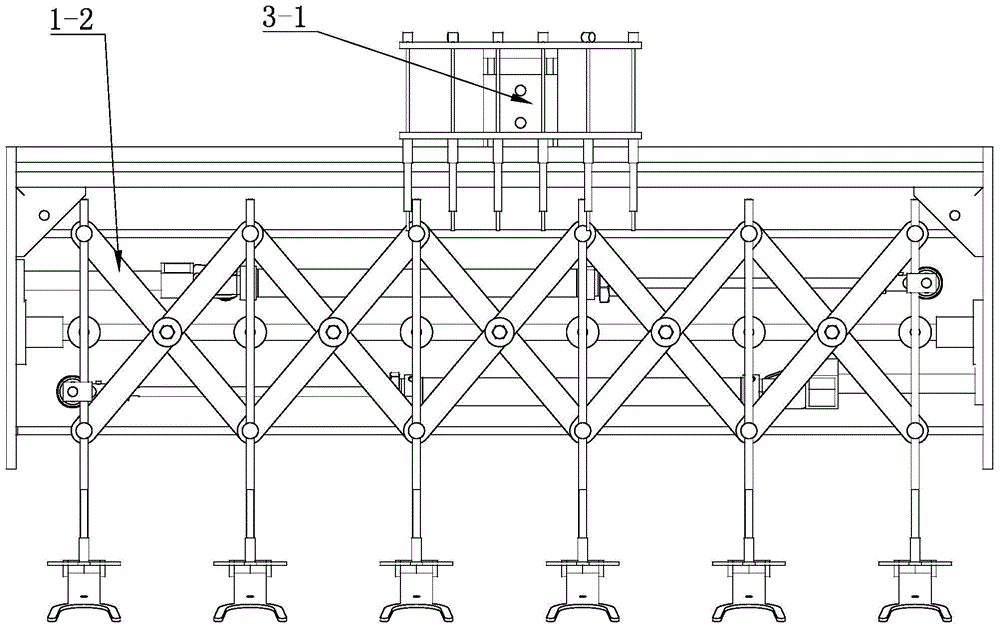

[0022] Such as figure 1 In the shown scissor-type variable-pitch shifting manipulator, several clamping pallets (formed by the hinged opening and closing of the upper pallet 2-1 and the lower pallet 2-2) for clamping the seedling cup 6 are positioned On the frame; the steel wire tensioning mechanism exerts a clamping force on the clamping pallet, so that the clamping pallet clamps the seedling cup during the moving process; the scissors mechanism carries the clamping pallet, (Syringe cylinder is recommended) 1-1 is driven in opposite directions to adjust the distance between the clamping pallets.

[0023] The scissors mechanism includes two scissors, the two scissors are arranged in parallel and combined into one through s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com