A kind of walnut syrup and preparation method thereof

A technology of walnut dew and walnut kernels, which is applied in the field of walnut dew and its preparation, can solve the problems of high additive content and low additive content, and achieve the effects of low additive volume, milky white color and guaranteed nutritional content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention also relates to the preparation method of above walnut dew, and described preparation method comprises the following steps:

[0029] a. The walnut kernels are treated with lye, peeled, and refined to obtain walnut kernel pulp, wherein the weight percentage of walnut kernels and lye is 1: (2-25), preferably 1:5, and set aside;

[0030] b. Prepare a mixed solution of compound emulsifying thickener, white granulated sugar, sodium carbonate and deionized water according to the weight percentage, dissolve the compound emulsifying thickener, white granulated sugar and sodium carbonate in deionized water, and ensure the compounding The ratio of the weight of emulsifying thickener, white sugar, and sodium carbonate to the weight of deionized water is controlled at 1: (1-6), preferably 1:2, and set aside;

[0031] c. Prepare the walnut pulp in step a and the mixed solution in step b, homogenize, fill and sterilize to obtain the walnut dew.

[0032] In the ...

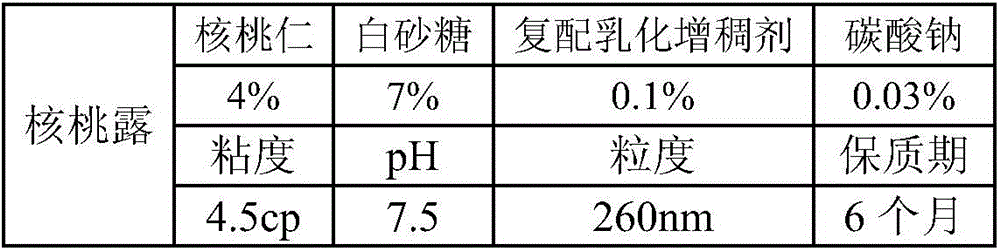

Embodiment 1

[0036] Embodiment 1 prepares the walnut dew that the additive content of the present invention is low

[0037] a. Add 40g of Hebei walnut kernels to 1000g of sodium hydroxide solution (concentration 1%, temperature 100°C) and boil for 5 minutes, spray and peel them with a high-pressure water gun, add the peeled walnut kernels to 300g of water, and use a colloid mill pulp, get the walnut kernel pulp for later use;

[0038] b. Mix 1.5g of monoglyceride, sodium caseinate, xanthan gum mixture, 70g of white sugar, 0.35g of sodium carbonate and 100g of water, the dissolution temperature is 75°C, the dissolution strength is 800rpm, the dissolution time is 10min, and the solution is ready for use ;

[0039]c. Blend the walnut pulp obtained in step a with the mixed solution obtained in step b. The blending time is 10 minutes, and the blending intensity is stirred at 800 rpm; the homogenization temperature is 70°C, the homogenization pressure is 35Mpa, and the homogenization times is 2...

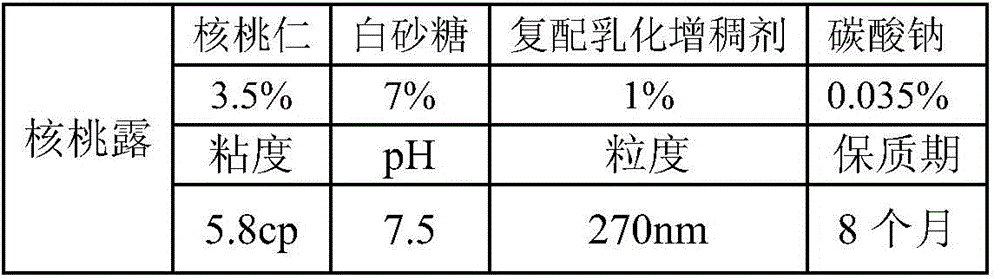

Embodiment 2

[0043] Embodiment 2 prepares the walnut dew that the additive content of the present invention is low

[0044] a. Add 35g of Shanxi walnut kernels to 500g of potassium hydroxide solution (concentration 0.5%, temperature 100°C) and soak for 15min, then spray and peel them with a high-pressure water gun, add the peeled walnut kernels to 200g of water, and use colloidal milling pulp, get the walnut kernel pulp for later use;

[0045] b. Mix 1.5g carrageenan, monoglyceride, sucrose ester mixture, 70g white granulated sugar, 0.35g sodium carbonate and 125g water, the dissolution temperature is 90°C, the dissolution strength is 30000rpm, the dissolution time is 25min, and the solution is ready for use;

[0046] c. Blend the walnut pulp obtained in step a with the mixed solution obtained in step b. The blending time is 30 minutes, and the blending intensity is stirred at 30,000 rpm; the homogenization temperature is 85°C, the homogenization pressure is 40Mpa, and the homogenization t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com