Gallbladder preserving and calculus removing operation sheath tube

A sheath tube and sheath core technology, which is applied in the field of gallbladder preservation and stone extraction operation sheath tube, can solve the problems of difficult gallbladder removal, difficult removal of stones, and damage to the gallbladder mucosa, and achieves the effects of high transparency, simple structure, and reduction of mucosal damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

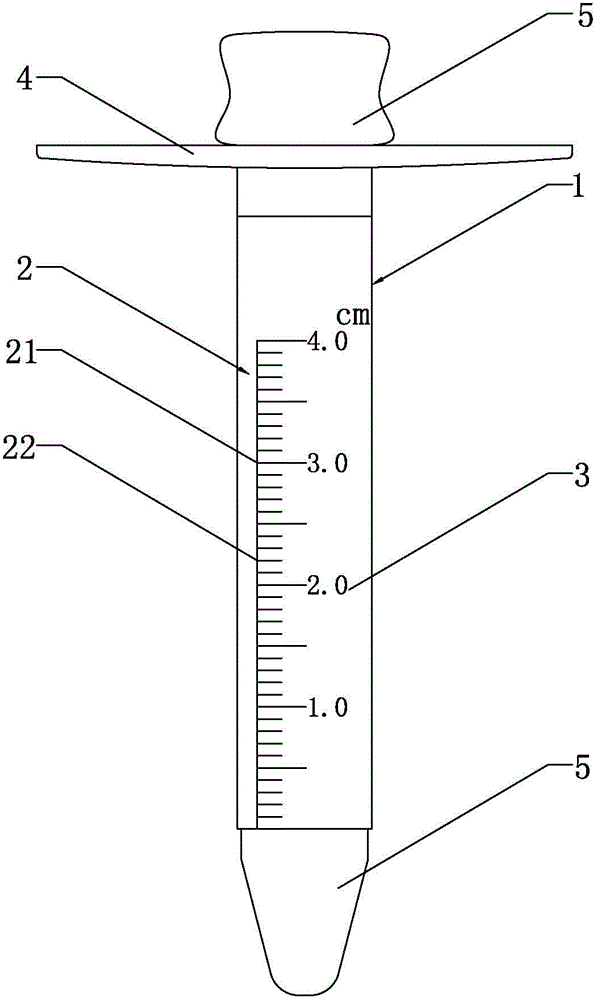

[0026] See figure 1 , a sheath for gallbladder stone removal operation, comprising a sheath body 1 and a sheath core 5 sheathed in the sheath body 1, the outer wall of the sheath body 1 is provided with a scale 2 and a scale value 3, and the scale 2 includes Long scale 21 and short scale 22, four short scales 22 are arranged between adjacent two long scales 21, the distance between adjacent two long scales 21 is 0.5cm, the distance between adjacent two short scales 22 The distance is 0.1 cm, the scale value 3 is set on one side of the long scale 21 , and a scale value 3 is set every two long scales 22 from the front end of the sheath body 1 .

[0027] In this embodiment, the inner diameter of the sheath body 1 is 8 mm, and the wall thickness is 0.5 mm; the length of the sheath body 1 is 4.5 cm, and the length of the scale 2 is 3.5 cm.

[0028] In this embodiment, the two sides of the rear end of the sheath tube body 1 are respectively protruded with lugs 4; the outer side wa...

Embodiment 2

[0043] The difference between this embodiment and the above-mentioned embodiment 1 is that: the inner diameter of the sheath body 1 is 9 mm, and the wall thickness is 0.6 mm; the length of the sheath body 1 is 10 cm, and the length of the scale 2 is 8 cm .

[0044] The sheath tube body 1 is made of medical polypropylene material through injection molding, and the medical polypropylene material includes the following raw materials in parts by weight:

[0045]Resin base material 90 parts

[0046] Nucleating agent 0.75 parts

[0047] Lubricant 1 part

[0048] Antioxidant 0.6 part;

[0049] Wherein, the resin base material is a mixture composed of homopolypropylene, random copolymerized polypropylene and ethylene-propylene random copolymer in a weight ratio of 1:0.8:1.5. The homopolypropylene is a homopolypropylene with a melting temperature of 145°C and a melt flow rate of 15g / 10min; the random copolymerized polypropylene is a melt temperature of 142°C and a melt flow rate of...

Embodiment 3

[0054] The difference between this embodiment and the above-mentioned embodiment 1 is that: the inner diameter of the sheath body 1 is 10 mm, and the wall thickness is 0.7 mm; the length of the sheath body 1 is 5 cm, and the length of the scale 2 is 4 cm .

[0055] The sheath tube body 1 is made of medical polypropylene material through injection molding, and the medical polypropylene material includes the following raw materials in parts by weight:

[0056] 100 parts resin base

[0057] Nucleating agent 1 part

[0058] Lubricant 1.5 parts

[0059] Antioxidant 0.7 part;

[0060] Wherein, the resin base material is a mixture composed of homopolypropylene, random copolymerized polypropylene and ethylene-propylene random copolymer in a weight ratio of 1:1:2. The homopolypropylene is a homopolypropylene with a melting temperature of 150°C and a melt flow rate of 25g / 10min; the random copolymerized polypropylene is a melt temperature of 144°C and a melt flow rate of 22g / 10min ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com