Method for preparing white carbon black from diatomite in situ

A technology for in-situ preparation and diatomaceous material, applied in the chemical industry, can solve problems such as complex purification procedures, and achieve the effects of shallow burial, simple process, and easy open mining.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] a. Preparation of sodium silicate glass liquid: pulverize diatomaceous clay, add sodium hydroxide and water to stir and boil for reaction, then cool, age and filter to obtain sodium silicate glass liquid;

[0022] B, the preparation of white carbon black mixed solution: add a small amount of sodium sulfate to mix and stir in sodium silicate glass liquid, then carry out precipitation to sodium silicate glass liquid with sulfuric acid solution and make white carbon black mixed liquid;

[0023] c. Preparation of white carbon black: heat the white carbon black mixture for aging treatment, then wash, filter, and dry to obtain the white carbon black product.

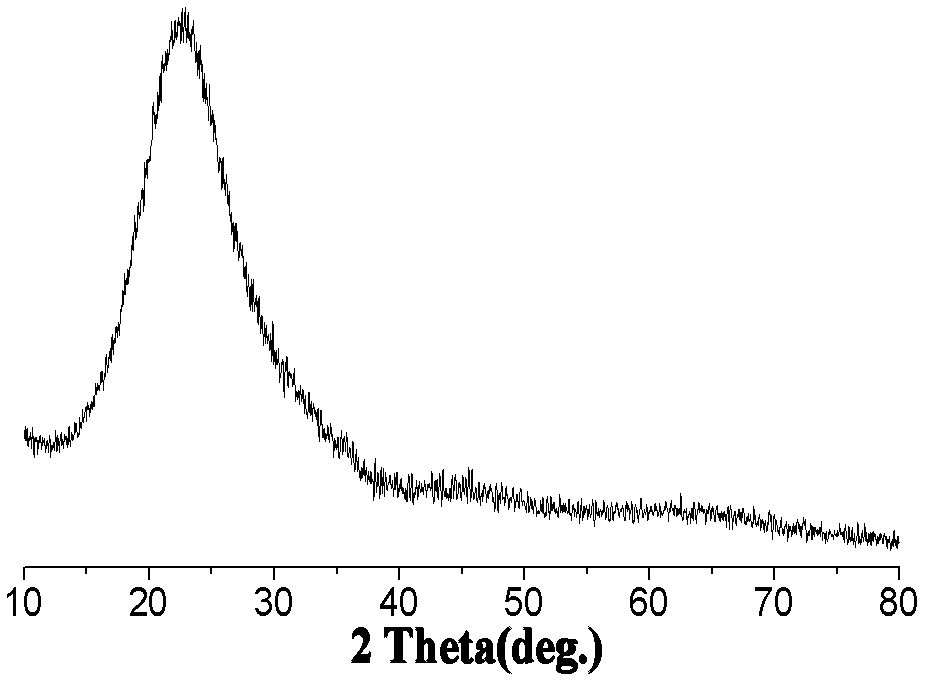

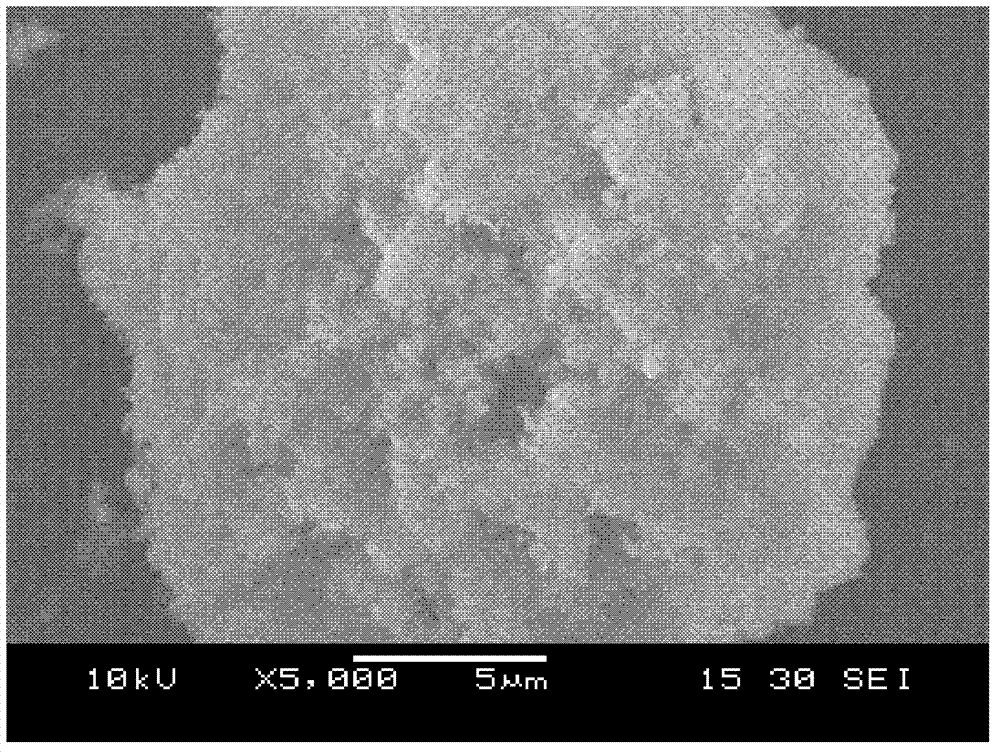

[0024] The present invention directly utilizes the diatomite clay to prepare the white carbon black in situ process, which can reduce the process of purifying the diatomite clay specially, and the process is simple. The produced silica is of good quality, from figure 1 It can be seen that silica contains less impuritie...

Embodiment 1

[0031] Diatomaceous clay (containing SiO by weight 2 59.07%, Fe 3 o 36.32%, Al 2 o 3 15.01%) 10g was crushed to about 65 mesh, with diatomaceous clay: NaOH: water = 10g: 6g: 100g, stirred evenly, boiled for 1.5h; cooled and aged at room temperature for 1h to form a sodium silicate glass liquid with a modulus of 0.76 ; Use a vacuum pump to filter and separate the non-alkali-soluble solid and sodium silicate glass liquid. The conditions are: speed: 1400rad / min, 120W, ultimate pressure: 6Pa, pumping speed 1-1.1L / s, about: 5-6min; Add 1g of sodium sulfate to every 100ml of sodium silicate glass liquid, mix and stir, use 2mol / L sulfuric acid solution to precipitate the sodium silicate glass liquid, at a temperature of 75°C, a speed of 600 rad / min, for about 2 hours, and titrate to pH Stop acid dripping at 6.5, and carry out aging treatment for 20min at the temperature of 85°C to the prepared white carbon black mixture; put it into a 1000ml beaker and add 1000ml water to wash th...

Embodiment 2

[0033] Diatomaceous clay (containing SiO by weight 2 59.07%, Fe 2 o 3 6.32%, Al 2 o 3 14.86%) 10g was crushed to about 70 mesh, with diatomaceous clay: NaOH: water = 10g: 6g: 100g, stirred evenly, boiled for 1.5h; cooled and aged at room temperature for 1h to form a sodium silicate glass liquid with a modulus of 0.75 ; Use a vacuum pump to filter and separate the non-alkali-soluble solid and sodium silicate glass liquid. The conditions are: speed: 1400rad / min, 120W, ultimate pressure: 6Pa, pumping speed 1-1.1L / s, about: 5-6min; Add 1g of sodium sulfate to every 100ml of sodium silicate glass liquid, mix and stir, use 2mol / L sulfuric acid solution to precipitate the sodium silicate glass liquid, at a temperature of 70°C, a speed of 600 rad / min, for about 2 hours, and titrate to pH Stop acid dripping at 6.5, and carry out aging treatment for 15 minutes at the temperature of 90°C to the prepared white carbon black mixture; put it into a 1000ml beaker and add 1000ml of water t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com