Method for extracting persimmon polyphenol from persimmons

A technology of persimmon and ethyl acetate is applied in the directions of pharmaceutical formulations, medical preparations containing active ingredients, plant raw materials, etc., which can solve the problems of cumbersome operation process, difficulty in meeting production requirements, destroying the structure of persimmon polyphenols, etc., and achieves simple operation. Easy to implement, improve product yield, and shorten the effect of extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

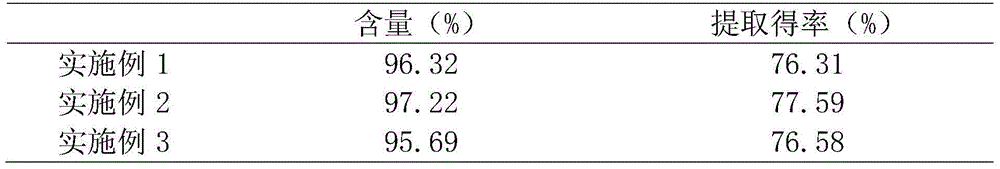

Embodiment 1

[0019] A method for extracting persimmon polyphenols from persimmons, comprising the steps of:

[0020] 1) Raw material processing: 10kg of persimmons that are seven to eighty percent ripe are washed and crushed;

[0021] 2) Ultra-high pressure treatment: add 50kg of pure water to the crushed persimmons, pressurize at 350MPa, apply temperature at 50°C, and perform ultra-high pressure treatment for 2 minutes;

[0022] 3) Ultrasonic treatment: The solution obtained in step 2) was subjected to ultrasonic treatment for 8 minutes, the action temperature was 40°C, and the power was 300W;

[0023] 4) Extraction: filter the solution obtained in step 3), and repeatedly extract with ethyl acetate equal to the volume of the filtrate until the ethyl acetate phase is colorless, and collect and combine the ethyl acetate phase;

[0024] 5) Drying: Concentrate the ethyl acetate phase obtained in step 4), and remove the ethyl acetate in the ethyl acetate phase by evaporation at a temperature ...

Embodiment 2

[0026] A method for extracting persimmon polyphenols from persimmons, comprising the steps of:

[0027] 1) Raw material processing: 10kg of persimmons that are seven to eighty percent ripe are washed and crushed;

[0028] 2) Ultra-high pressure treatment: Add 100kg of pure water to the crushed persimmons, press 350MPa, apply temperature 40°C, and perform ultra-high pressure treatment for 5 minutes;

[0029] 3) Ultrasonic treatment: process the solution obtained in step 2) for 5 minutes with ultrasonic treatment at a temperature of 45°C and a power of 300W;

[0030] 4) Extraction: filter the solution obtained in step 3), and repeatedly extract with ethyl acetate equal to the volume of the filtrate until the ethyl acetate phase is colorless, and collect and combine the ethyl acetate phase;

[0031] 5) Drying: Concentrate the ethyl acetate phase obtained in step 4), and remove the ethyl acetate in the ethyl acetate phase by evaporation at a temperature not higher than 40°C to ob...

Embodiment 3

[0033] A method for extracting persimmon polyphenols from persimmons, comprising the steps of:

[0034] 1) Raw material processing: 10kg of persimmons that are seven to eighty percent ripe are washed and crushed;

[0035] 2) Ultra-high pressure treatment: Add 80kg of pure water to the crushed persimmons, press 350MPa, apply temperature 45°C, and perform ultra-high pressure treatment for 3 minutes;

[0036] 3) Ultrasonic treatment: The solution obtained in step 2) was ultrasonically treated for 10 minutes at a temperature of 50°C and a power of 300W;

[0037] 4) Extraction: filter the solution obtained in step 3), and repeatedly extract with ethyl acetate equal to the volume of the filtrate until the ethyl acetate phase is colorless, and collect and combine the ethyl acetate phase;

[0038] 5) Drying: Concentrate the ethyl acetate phase obtained in step 4), and remove the ethyl acetate in the ethyl acetate phase by evaporation at a temperature not higher than 40°C to obtain pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com