Special equipment for manufacturing nano micro-pore air purification net

An air purification, nano-microporous technology, applied in the field of filters, can solve the problems of high price of air purifiers, loss of adsorption capacity, short service life, etc., and achieve excellent anti-dust adsorption performance, not easy to condense, and excellent water blocking performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

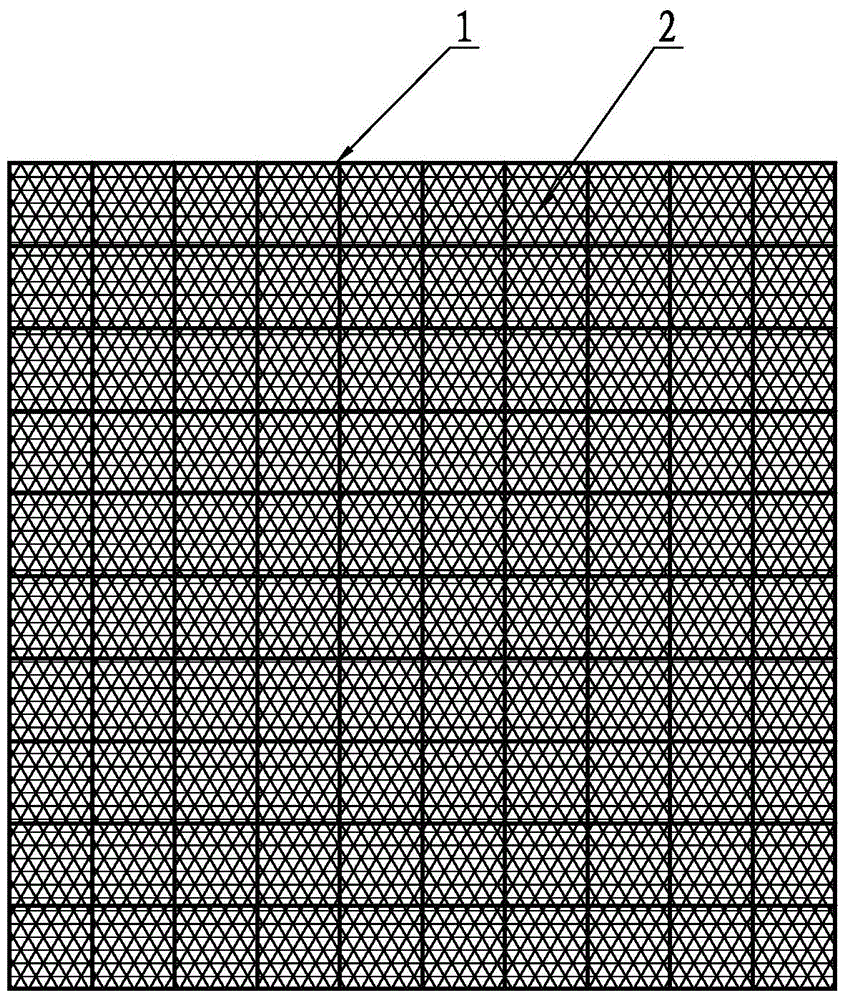

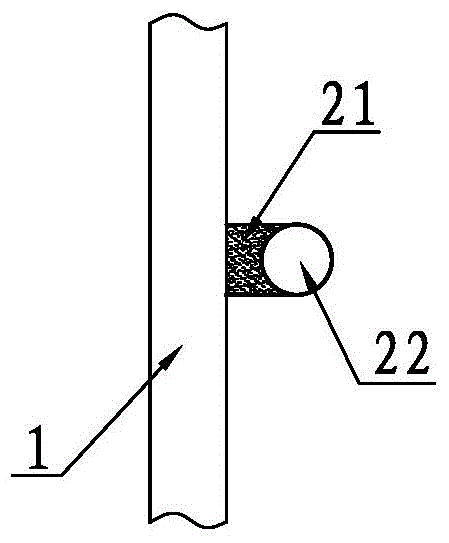

[0019] A kind of nano microporous air purification net, such as figure 1 , figure 2 As shown, it is composed of a gauze base material 1 and a nanoporous membrane 2, and the nanoporous membrane 2 is composed of a cured colloid 21 and nanofiber chopped strands 22, and the nanofiber chopped strands 22 are bonded in a criss-cross pattern. Micropores with a diameter of 0.1 micron to 2.5 microns are formed on the cured colloid 21 , and the nano-microporous membrane 2 is fixed on the gauze substrate 1 by adhesive curing and interlocking.

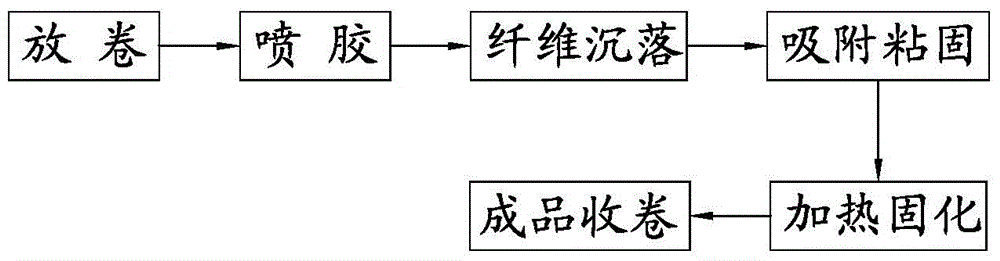

[0020] The preparation process of nano-microporous air purification net is as follows: image 3 As shown, unwinding - glue spraying - fiber sinking - adsorption reinforcement - heating and curing - finished product winding.

[0021] A kind of equipment for preparing nano-microporous air purification net, such as Figure 4 As shown, it includes a driven shaft 3, a driving shaft 4, two transition rollers 5, a nanofiber settling flat barrel 6, a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com