Battery washing machine

A cleaning machine and cleaning mechanism technology, applied in cleaning methods and utensils, cleaning methods using tools, cleaning methods using liquids, etc., can solve problems such as low efficiency of manual cleaning of batteries, and achieve convenient continuous cleaning, saving manpower, avoiding The effect of cross contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

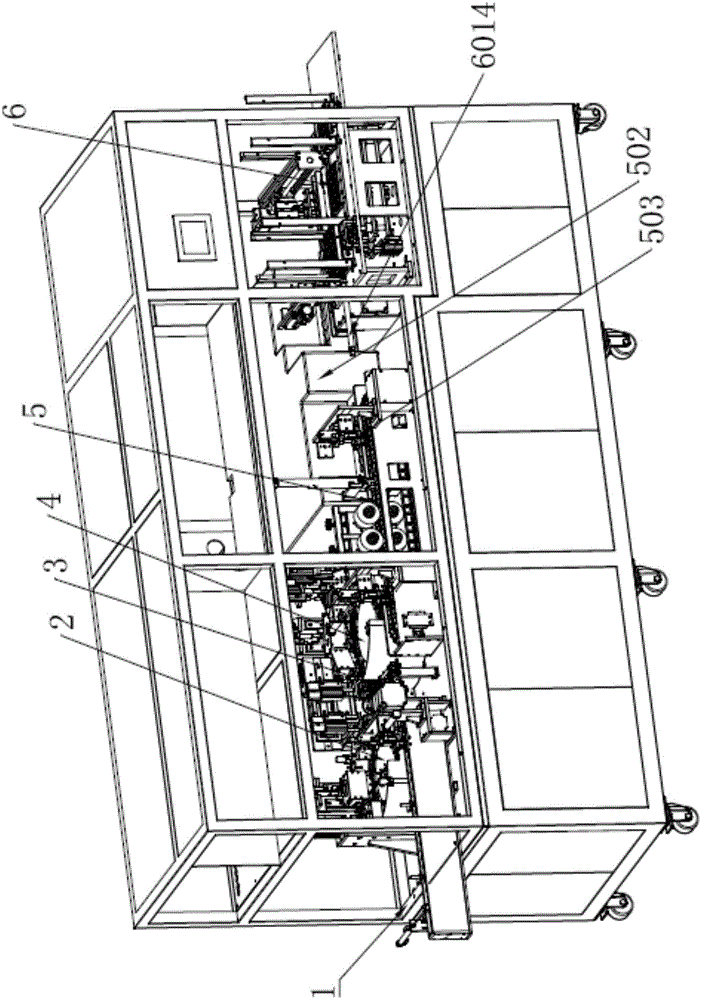

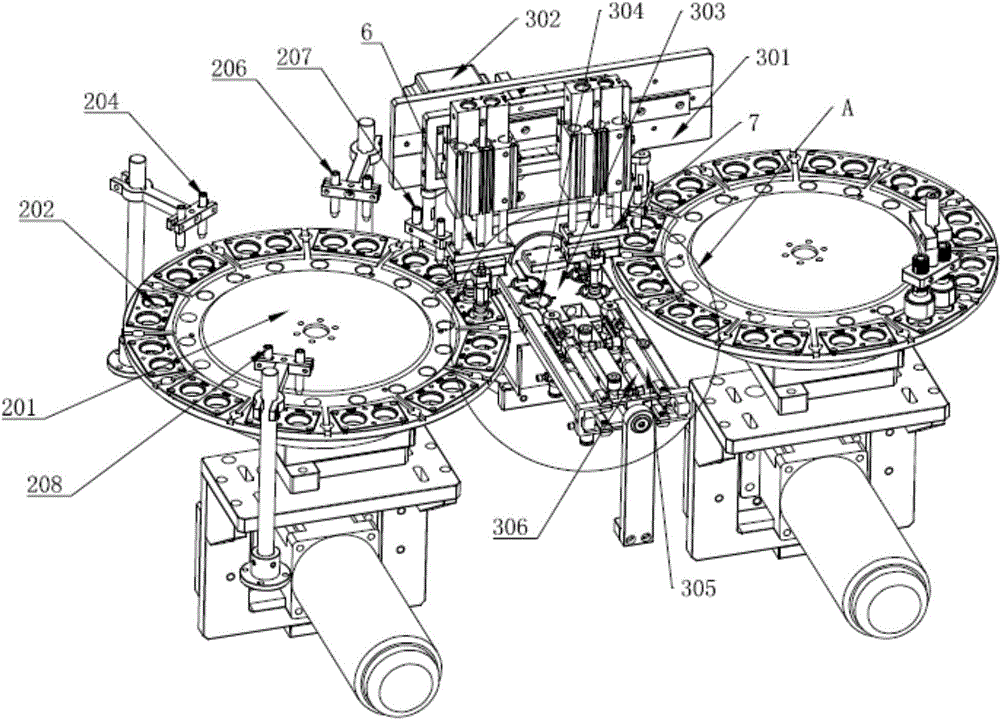

[0026] Such as figure 1 As shown, the present embodiment provides a battery cleaning machine, which includes a frame 1, and the frame 1 is sequentially provided with a first transmission mechanism 1 for inputting batteries, a battery front cleaning mechanism 2, an overturning mechanism 3, and a reverse side of the battery. The washing mechanism 4, the battery drying mechanism 5 and the receiving mechanism 6 are provided with transfer manipulators for sequentially transferring the batteries to the corresponding next mechanism. This application adopts continuous production, and the front and back of the battery can be quickly switched through the flipping mechanism, which is convenient for continuous cleaning; each mechanism is taken out in time by the transfer robot to avoid cross-contamination, and automatically dry and collect materials after cleaning, saving manpower. Easy to operate.

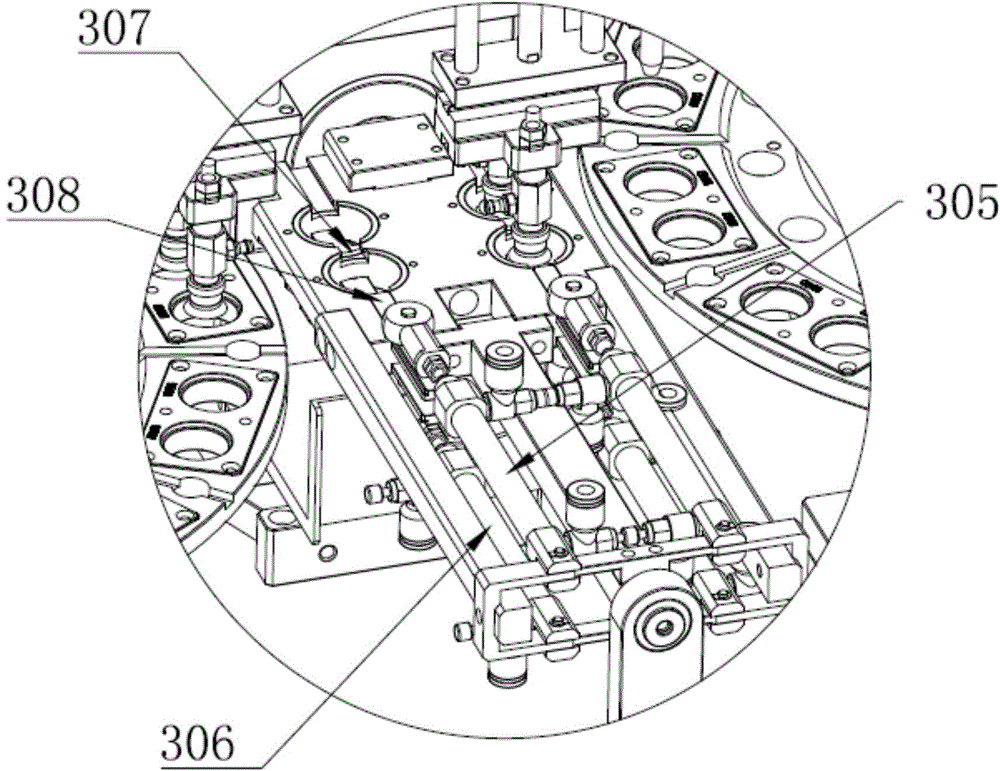

[0027] The turning mechanism 3 includes a turning support plate 301 and a turning motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com