Technology for connecting same or different metal material pipes in rotary forging mode

A technology of dissimilar metals and pipe fittings, applied in the field of connection technology, can solve the problems of single stress point, easy damage, and inability to use welding, etc., and achieve the effect of reliable connection, efficient and reliable process, and uniform connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with example the present invention will be further described.

[0016] Now there are two kinds of materials, the small pipe 1 is titanium alloy, the outer diameter is 25mm, the wall thickness is 2.5mm, the inner hole diameter is 20mm, the large pipe 2 is stainless steel, the outer diameter is 32mm, the wall thickness is 3.3mm, the inner hole diameter is 25.4mm, now The two materials need to be connected. After the connection is completed, the torsion resistance should be >500N.M, and the tensile strength should be >3KN.

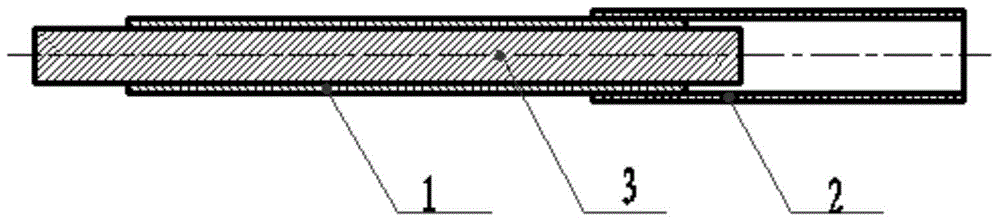

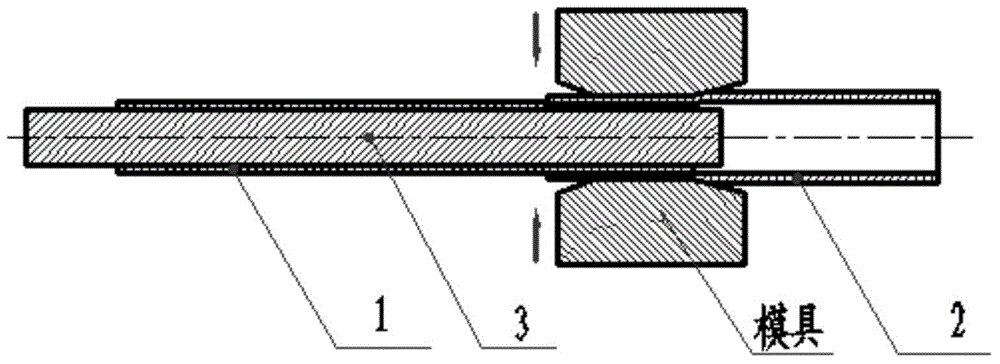

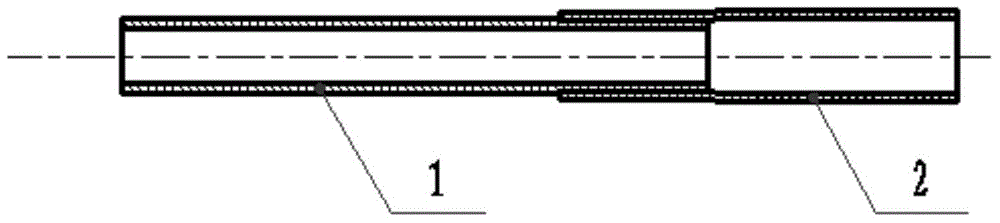

[0017] Such as figure 1 , figure 2 , image 3 As shown, the connection is performed by the swaging process below, including the following steps:

[0018] 1. Prepare a mandrel 3, the diameter of the mandrel is 20mm, the material of the mandrel is W18Cr4V, the heat treatment is HRC58, the surface is finely ground, the roughness is <0.4, and the surface is coated with titanium nitride to increase its hardness and smoothness Spend...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com