Automatic point spraying device for casting blank

A slab casting and automatic technology, applied in the field of metallurgical equipment, can solve problems such as forgetting to spray, passive production, low operating rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

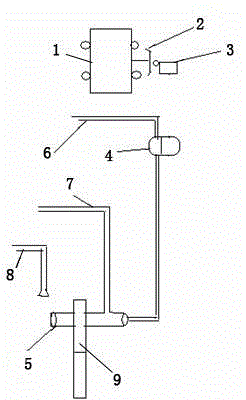

[0018] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

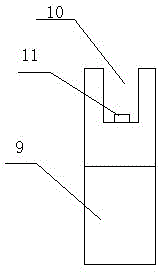

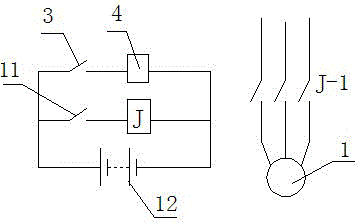

[0019] It can be seen from the accompanying drawings that a slab automatic spraying device of this scheme includes a compressed gas supply pipe 6, a limit baffle 2 fixed on the cutting machine 1, and the limit baffle 2 and the cutting machine 1 are welded or bolted. A limit switch 3 cooperating with the limit baffle plate 2 is arranged on one side of the billet, the limit switch 3 is connected in series with the solenoid valve 4 and then connected in series with a power supply 12, and the power supply 12 is 24V DC power supply. The compressed gas supply pipe 6 communicates with the nozzle 5 for spraying, the solenoid valve 4 is arranged on the compressed gas supply pipe 6, and a high temperature resistant paint pipe 7 communicates with the nozzle 5. The nozzle 5 is fixed on the noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com