Multi-functional Mechanical Measuring Tapping Device

A multi-functional machine and tapping device technology, applied in the direction of thread cutting device, measuring/indicating equipment, metal processing machinery parts, etc., can solve problems such as impatience, unclear tools, broken turning tools, etc., to achieve ingenious structural design, Improved accuracy, practical and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

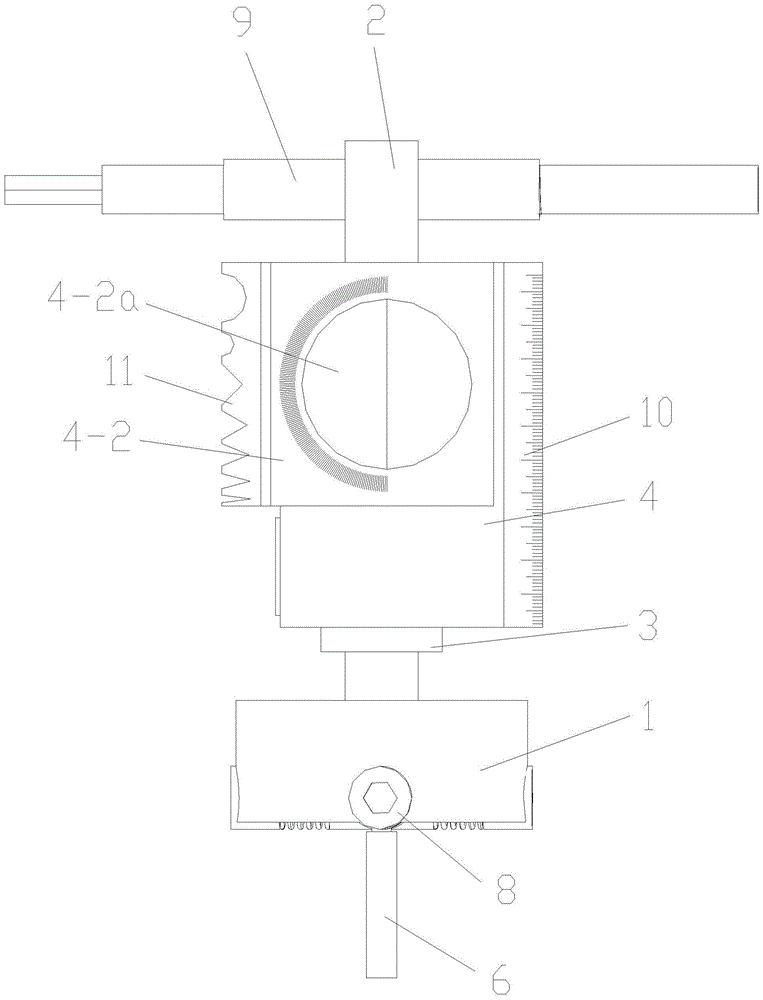

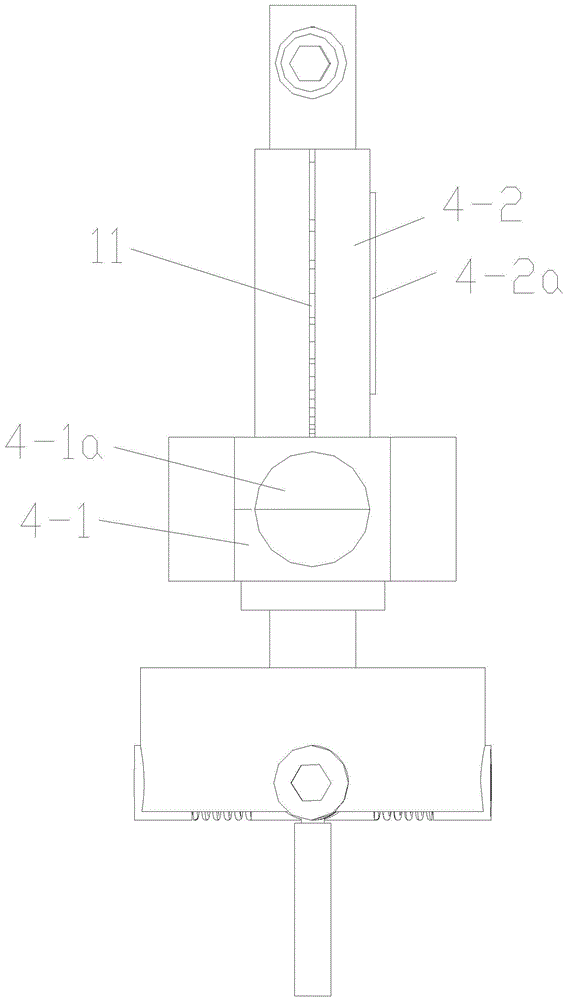

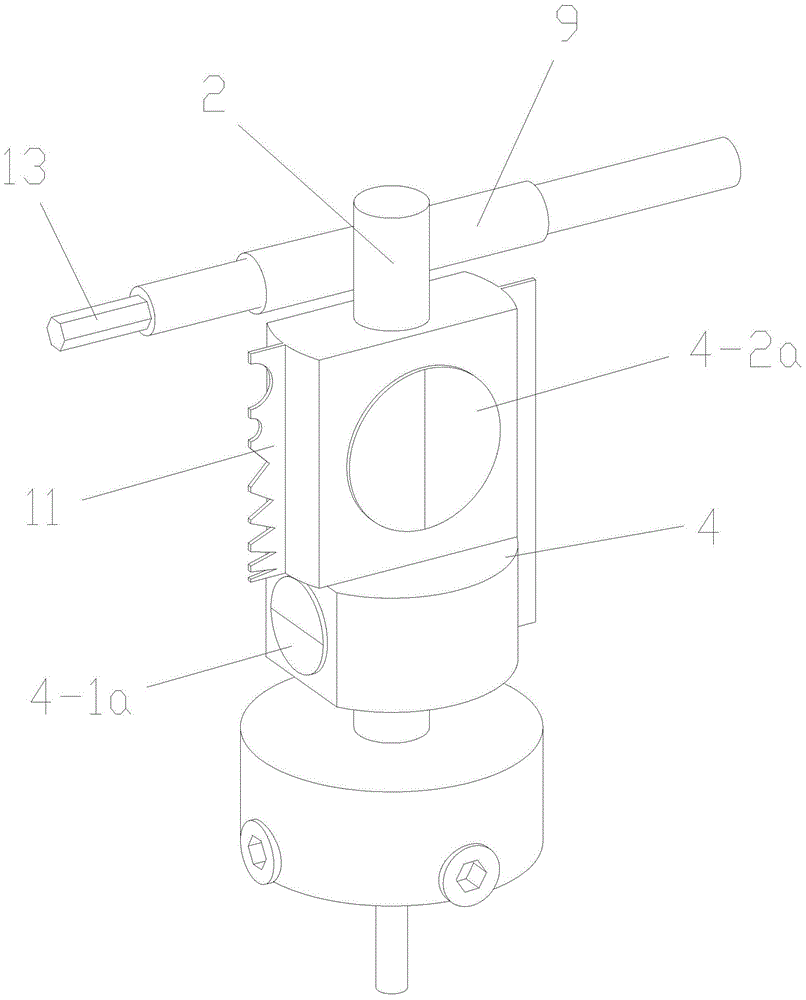

[0021] With reference to accompanying drawing: among the present embodiment, multi-function mechanical measurement tapping device comprises base 1, and the lower surface 1-1 of base 1 is a horizontal plane, and the upper surface of base 1 is fixed with the fixed column 2 perpendicular to lower surface 1-1, A bearing 3 is installed outside the fixed column 2, and a measuring instrument 4 is installed on the bearing 3. The measuring instrument 4 is fixed outside the bearing 3 and is socketed outside the fixed column 2. The measuring instrument 4 includes a level measuring instrument 4-1 and a verticality measuring instrument 4-2, the level measuring instrument 4-1 includes a level indicator 4-1a installed in the measuring instrument, the level indicator 4-1a is engraved with a horizontal line, the level measuring instrument 4-1 is engraved with a horizontal calibration line, v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com