Explosion-proof wall manufactured through foamed aluminum of sandwich structure

A foam aluminum, explosion-proof wall technology, used in electric power units, power units, transportation and packaging, etc., can solve the problems of passive explosion-proof and lack of effective measures for personnel protection, to improve safety and stability, excellent fire protection, protection The effect of personnel safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

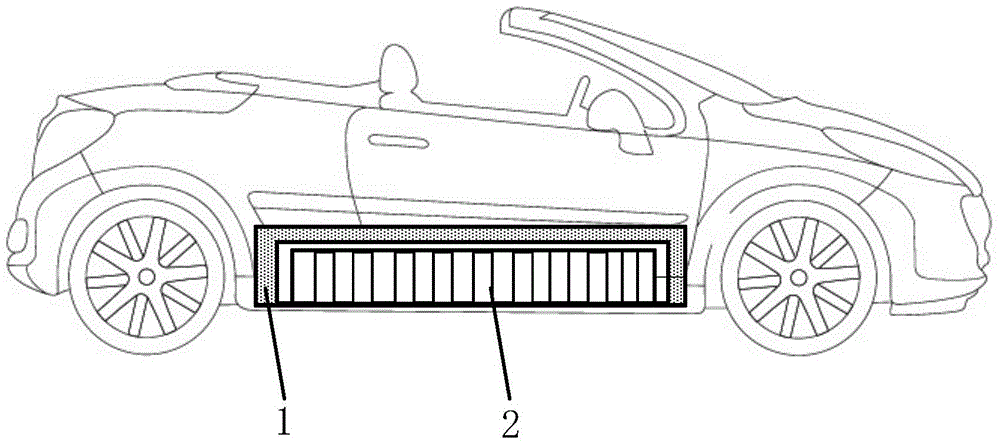

[0013] combine figure 1 To illustrate a preferred solution for an explosion-proof wall using aluminum foam in a sandwich structure based on the content of the present invention.

[0014] Aluminum foam sheet with a porosity of 90% and a density of 0.27 g / cm 3 , the coefficient of thermal expansion is (14~16)×10 -6 / °C, the energy absorption rate is 20~30J / cm 3 . .

[0014] Aluminum foam sheet with a porosity of 90% and a density of 0.27 g / cm 3 , the coefficient of thermal expansion is (14~16)×10 -6 / °C, the energy absorption rate is 20~30J / cm 3 . .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com