Device for suppressing radiation noise of plate, plate and vehicle

A technology for radiating noise and panels, applied in vehicle parts, sound-emitting equipment, transportation and packaging, etc., can solve the problems of high manufacturing process requirements, poor pressure resistance, and high use costs, and achieve low manufacturing process requirements, suppress radiation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0034] The present invention will be described in detail below with reference to the accompanying drawings and examples.

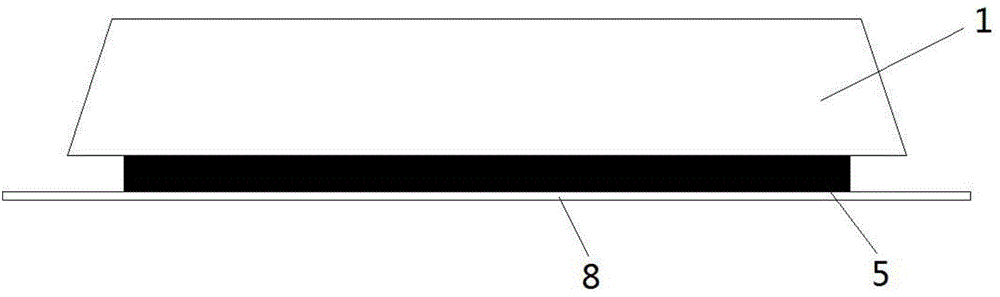

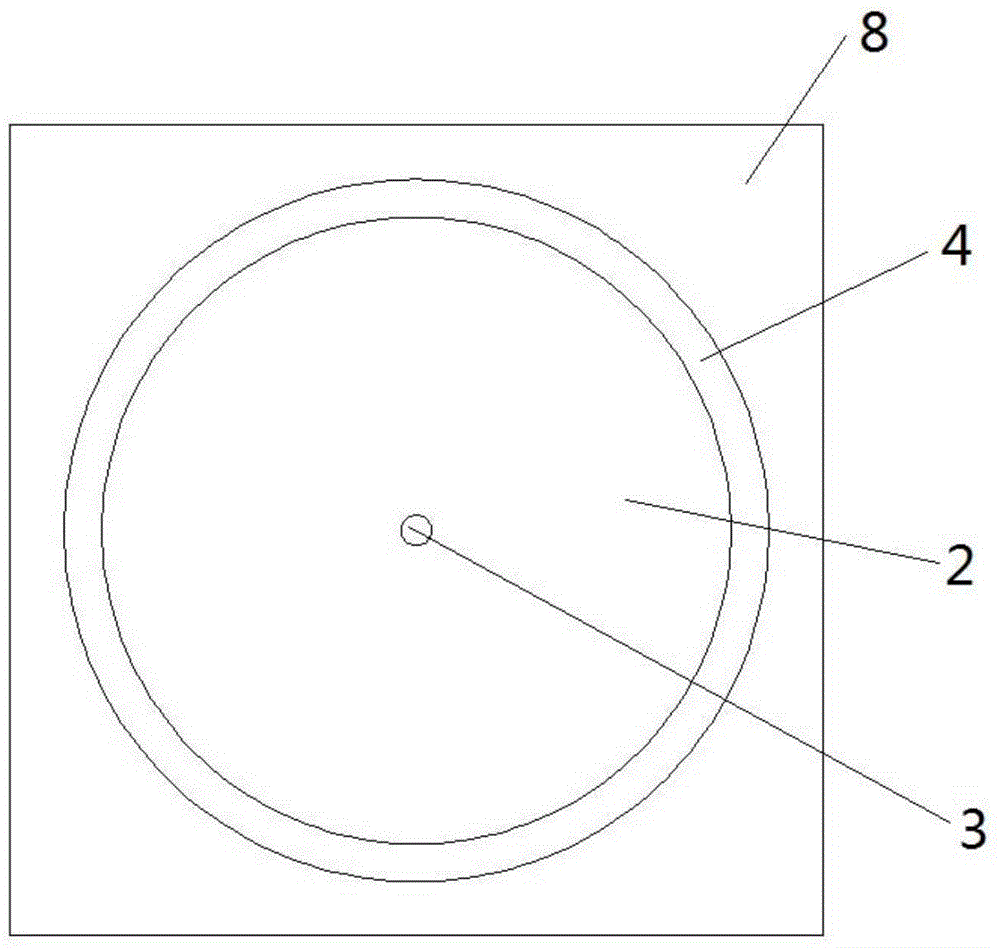

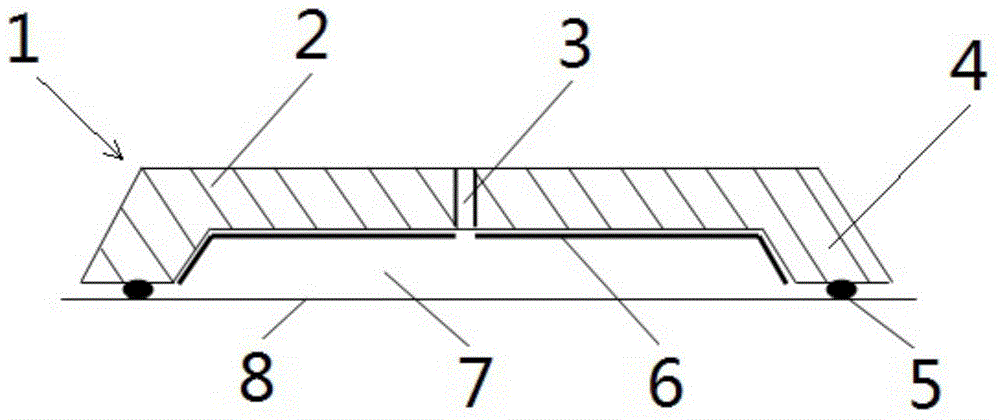

[0035] see figure 1 with figure 2 , a device for suppressing radiated noise from a panel, the device for suppressing radiated noise from a panel includes a sound-insulating part, the sound-insulating part includes a sound-insulating material part 1 for being installed on a panel 8, and the sound-insulating material part 1 and Cavities 7 are formed between the plates 8 .

[0036] The structure of the device for suppressing the radiated noise of the panel according to the present invention is simple, and the requirements for the manufacturing process are relatively low, so that the cost of the device for suppressing the radiated noise of the panel is relatively low, and because the gap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com