A controlled-release fertilizer coating system and its control method

A controlled-release fertilizer and coating technology, which is applied to fertilizer mixtures, layered/coated fertilizers, fertilization devices, etc., can solve the problems of slow-release fertilizer production and technical lag, low production efficiency, and high labor intensity. The effect of compact structure, improved production efficiency and improved control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

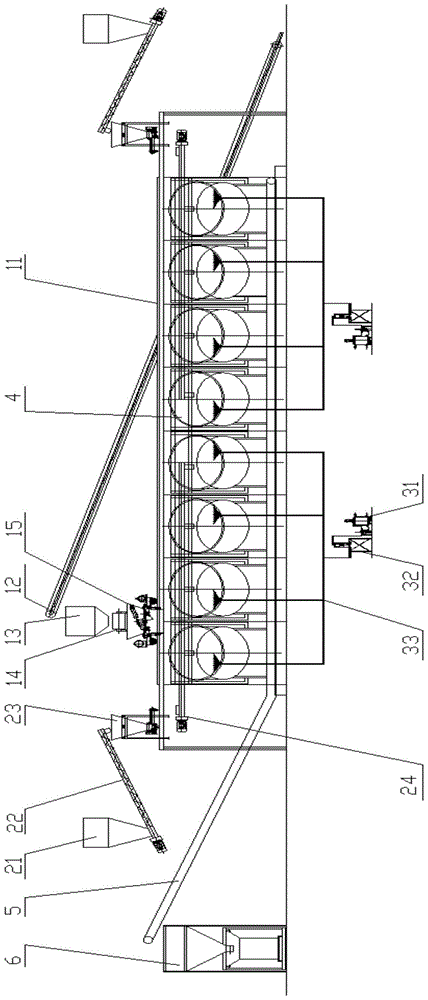

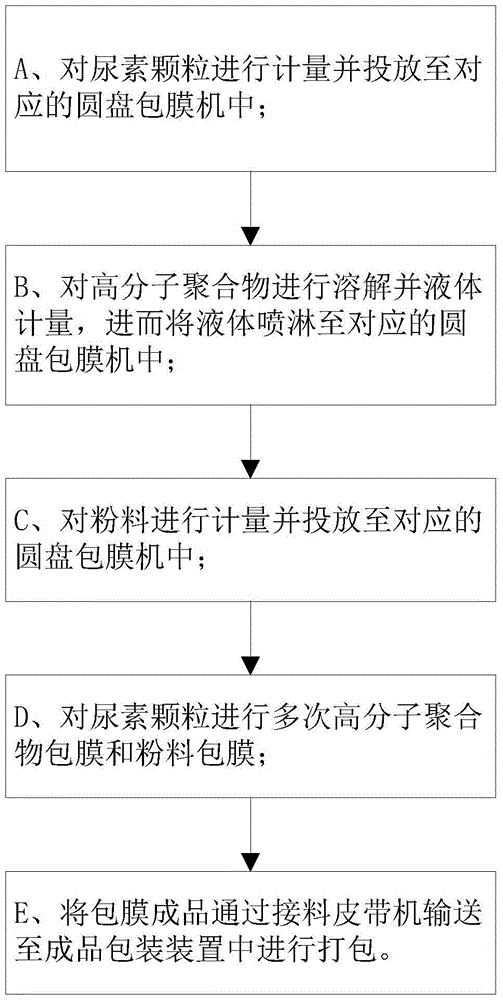

[0038] refer to figure 1 , a controlled-release fertilizer coating system of the present invention, comprising a urea metering delivery system 1, a powder metering delivery system 2, a liquid metering delivery system 3, a plurality of disk coating machines 4, a feeding belt conveyor 5, and a finished product packaging device 6 and a control computer, the material receiving belt conveyor 5 is located below the discharge port of the disc coating machine 4, the finished product packaging device 6 is located below one end of the material receiving belt conveyor 5, and the urea metering delivery system 1 , powder metering conveying system 2, liquid metering conveying system 3, multiple disk coating machines 4, material receiving belt conveyor 5 and finished product packaging device 6 are all connected to the control computer.

[0039] As a further improvement of the controlled-release fertilizer coating system, the urea metering delivery system 1 includes a machine moving channel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com