Site mixed emulsion explosive loader

A technology of emulsified explosives and on-site mixing, which is applied in the direction of explosives, explosive composite components, explosive processing equipment, etc., can solve the problems of high cost, latex matrix friction, hidden safety hazards, etc., and achieve the effect of reducing production costs and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

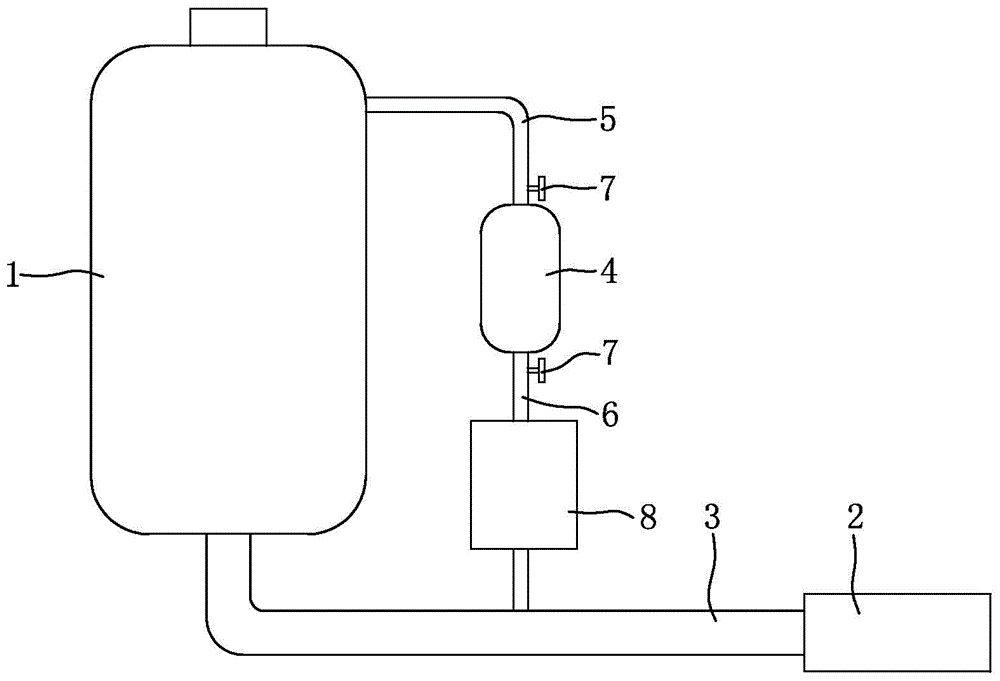

[0011] Such as figure 1 Shown, the present invention is made of latex matrix tank 1, static mixer 2, delivery pipe 3, high-pressure cylinder 4, first air pipe 5, second air pipe 6, valve 7 and blowing agent container 8 etc. Wherein, the top of the latex matrix tank 1 has a sealable feeding port, so that the latex matrix can be loaded into the latex matrix tank 1 through the feeding port. A discharge opening is provided at the central position of the bottom of the latex matrix tank 1 to facilitate discharge. A control valve can be installed at the discharge port to control the discharge volume. A conveying pipe 3 is arranged between the latex matrix tank 1 and the static mixer 2, and one end of the conveying pipe 3 is connected with the discharge port at the bottom of the latex matrix tank 1, and the other end of the conveying pipe 3 is connected with the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com