A method for extracting polysaccharide sulfate from kelp

A technology of polysaccharide sulfate and kelp, which is applied in the field of polysaccharide sulfate extraction, can solve the problems of low extraction rate, destroying the structure of polysaccharide sulfate, and difficulty in meeting production needs, so as to shorten extraction time, avoid changes, and improve product yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

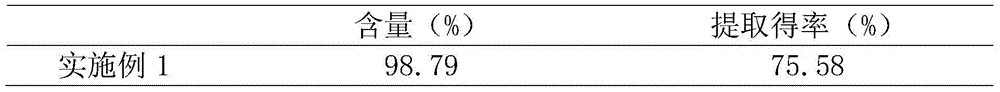

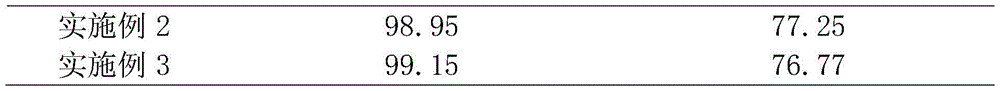

Examples

Embodiment 1

[0019] A method for extracting polysaccharide sulfate from kelp, comprising the steps of:

[0020] 1) Raw material processing: 10 kg of dried sea-tangle is pulverized;

[0021] 2) Ultra-high pressure treatment: add 400kg of pure water to the pulverized kelp, pressure 350MPa, temperature 85°C, ultra-high pressure treatment for 4 minutes, filter after completion, and collect the filtrate;

[0022] 3) Ultrasonic treatment: The filtrate obtained in step 2) was ultrasonically treated for 10 minutes at an operating temperature of 85°C and a power of 300W. After completion, filter and collect the filtrate;

[0023] 4) Enzymolysis: After adding protease to the filtrate obtained in step 3) to decompose protein into amino acids, first filter through an ultrafiltration membrane with a molecular weight cut-off of 1000-3000, and then concentrate through a nanofiltration membrane to 1 / 5 of the original volume to obtain crude Polysaccharide concentrate, wherein, the feeding amount of protea...

Embodiment 2

[0026] A method for extracting polysaccharide sulfate from kelp, comprising the steps of:

[0027] 1) Raw material processing: crush 10kg of fresh kelp;

[0028] 2) Ultra-high pressure treatment: add 600kg of pure water to the crushed kelp, pressure 350MPa, action temperature 80°C, ultra-high pressure treatment for 2min, filter after completion, and collect the filtrate;

[0029] 3) Ultrasonic treatment: The filtrate obtained in step 2) was ultrasonically treated for 8 minutes at an operating temperature of 80°C and a power of 300W. After completion, filter and collect the filtrate;

[0030] 4) Enzymolysis: After adding protease to the filtrate obtained in step 3) to decompose protein into amino acids, first filter through an ultrafiltration membrane with a molecular weight cut-off of 1000-3000, and then concentrate through a nanofiltration membrane to 1 / 5 of the original volume to obtain crude Polysaccharide concentrated solution, wherein, the feeding amount of protease is 1...

Embodiment 3

[0033] A method for extracting polysaccharide sulfate from kelp, comprising the steps of:

[0034] 1) Raw material processing: 10 kg of dried sea-tangle is pulverized;

[0035] 2) Ultra-high pressure treatment: Add 500kg of pure water to the pulverized kelp, pressure 350MPa, temperature 70°C, ultra-high pressure treatment for 5 minutes, filter after completion, and collect the filtrate;

[0036] 3) Ultrasonic treatment: process the filtrate obtained in step 2) for 5 minutes with ultrasonic treatment at a temperature of 70° C. and a power of 300 W. After completion, filter and collect the filtrate;

[0037] 4) Enzymolysis: After adding protease to the filtrate obtained in step 3) to decompose protein into amino acids, first filter through an ultrafiltration membrane with a molecular weight cut-off of 1000-3000, and then concentrate through a nanofiltration membrane to 1 / 5 of the original volume to obtain crude Polysaccharide concentrate, wherein, the feeding amount of protease...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com