Biodegradable material and preparation method thereof

A biodegradable material and biodegradable technology, applied in the field of biodegradable materials and their preparation, can solve problems such as global energy crisis and environmental pollution, achieve good application prospects, reduce energy consumption, and have good antistatic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of a biodegradable material comprises the following steps:

[0035] 1) Granulation: 21 kg of corn fiber and 9 kg of PP were mixed by a high-speed mixer, and then granulated by a twin-screw granulator; The section temperature is set to 120°C;

[0036] 2) Dehydration and cooling: Dehydrate the prepared granules, dry them, and air-cool them, then put them into a mixing bucket and stir for 30 minutes to mix well;

[0037] 3) Drying: Bake the cooled granules at 110°C for 35 minutes to obtain biodegradable granules;

[0038] 4) Injection molding: The obtained biodegradable particles are processed by conventional injection molding process to make a biodegradable plastic box.

Embodiment 2

[0040] A preparation method of a biodegradable material comprises the following steps:

[0041] 1) Granulation: 18 kg of corn fiber and 12 kg of elastomer were mixed by a high-speed mixer, and then granulated by a twin-screw granulator. The temperature of stage 5 is set to 120°C;

[0042] 2) Dehydration and cooling: Dehydrate the prepared granules, dry them, and air-cool them, then put them into a mixing bucket and stir for 30 minutes to mix well;

[0043] 3) Drying: Bake the cooled granules at 100°C for 40 minutes;

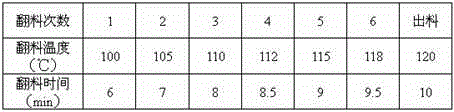

[0044] 4) Internal mixing: set the temperature of the internal mixer to 110°C, then put the dried granules into the internal mixer, add 0.32 kg of additives and mix for 10 minutes, and open the machine cover at different temperatures during mixing Turn over the material, the whole process is a total of 6 times, the process is as follows:

[0045]

[0046] 5) Opening: Set the temperature of the 18-inch open mill to 110°C, thin it twice to make the thickness ...

Embodiment 3

[0049] A kind of biodegradable material, its preparation method comprises the following steps:

[0050] 1) Granulation: 14 kg of corn fiber and 6 kg of elastomer were mixed by a high-speed mixer, and then granulated by a twin-screw granulator. The temperature of stage 5 is set to 120°C;

[0051] 2) Dehydration and cooling: Dehydrate the prepared granules, dry them, and air-cool them, then put them into a mixing bucket and stir for 30 minutes to mix well;

[0052] 3) Drying: Bake the cooled granules at 120°C for 30 minutes;

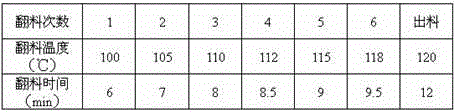

[0053] 4) Internal mixing: set the temperature of the internal mixer to 110°C, then put the dried granules into the internal mixer, add 0.31 kg of additives and mix for 12 minutes, and open the machine cover at different temperatures during mixing Turn over the material, the whole process is a total of 6 times, the process is as follows:

[0054]

[0055] 5) Opening: Set the temperature of the 18-inch open mill to 110°C, thin it twice to make the thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap