Method for preparing gyphosate solution from glyphosate raw material

A technology of technical medicine and water preparation, applied in the field of herbicides, can solve the problems of high toxicity of glyphosate dosage forms, greatly reduced herbicidal effect, and decreased yield, and achieve low production costs, high production safety, and good drug efficacy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

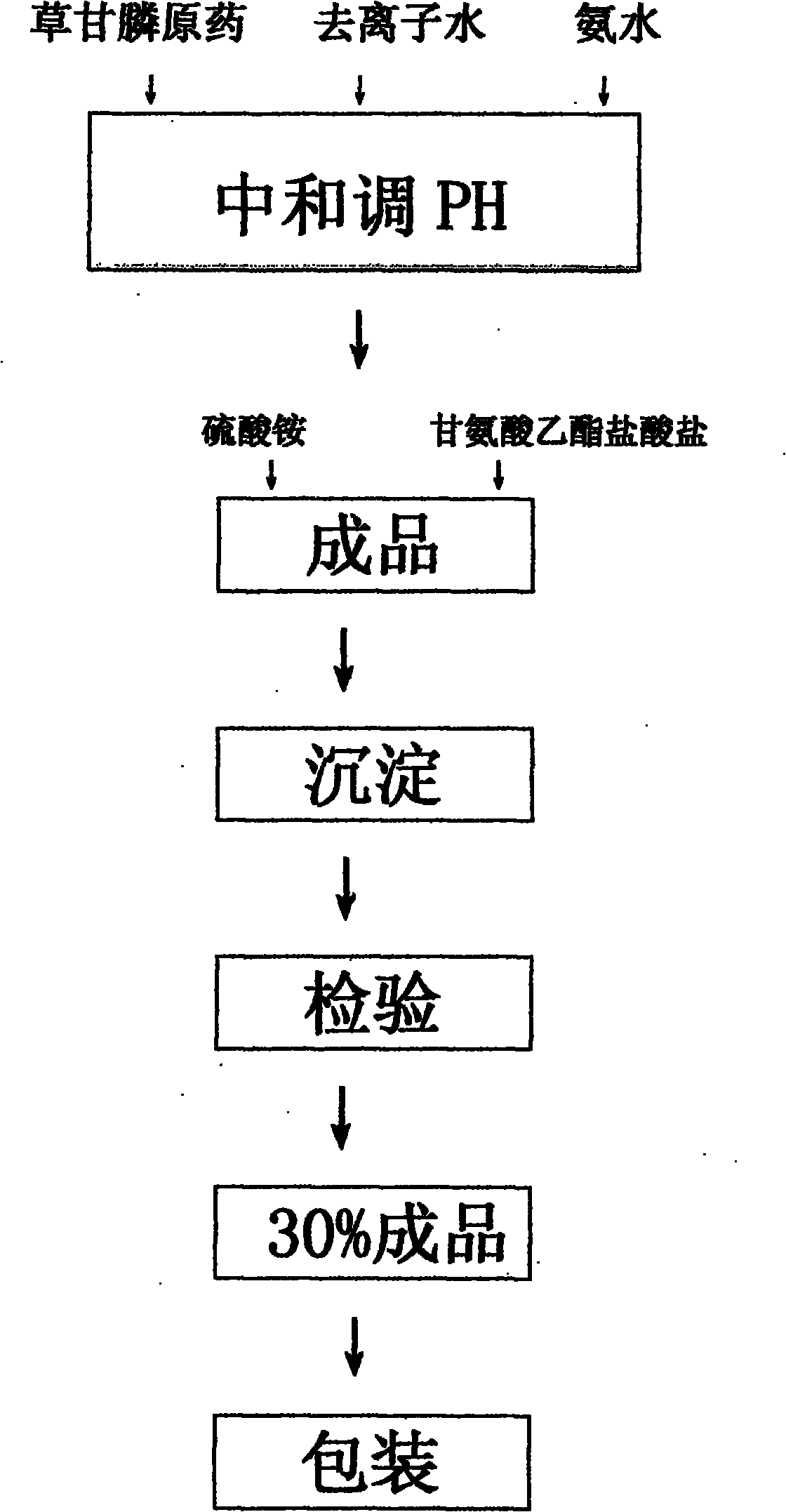

Method used

Image

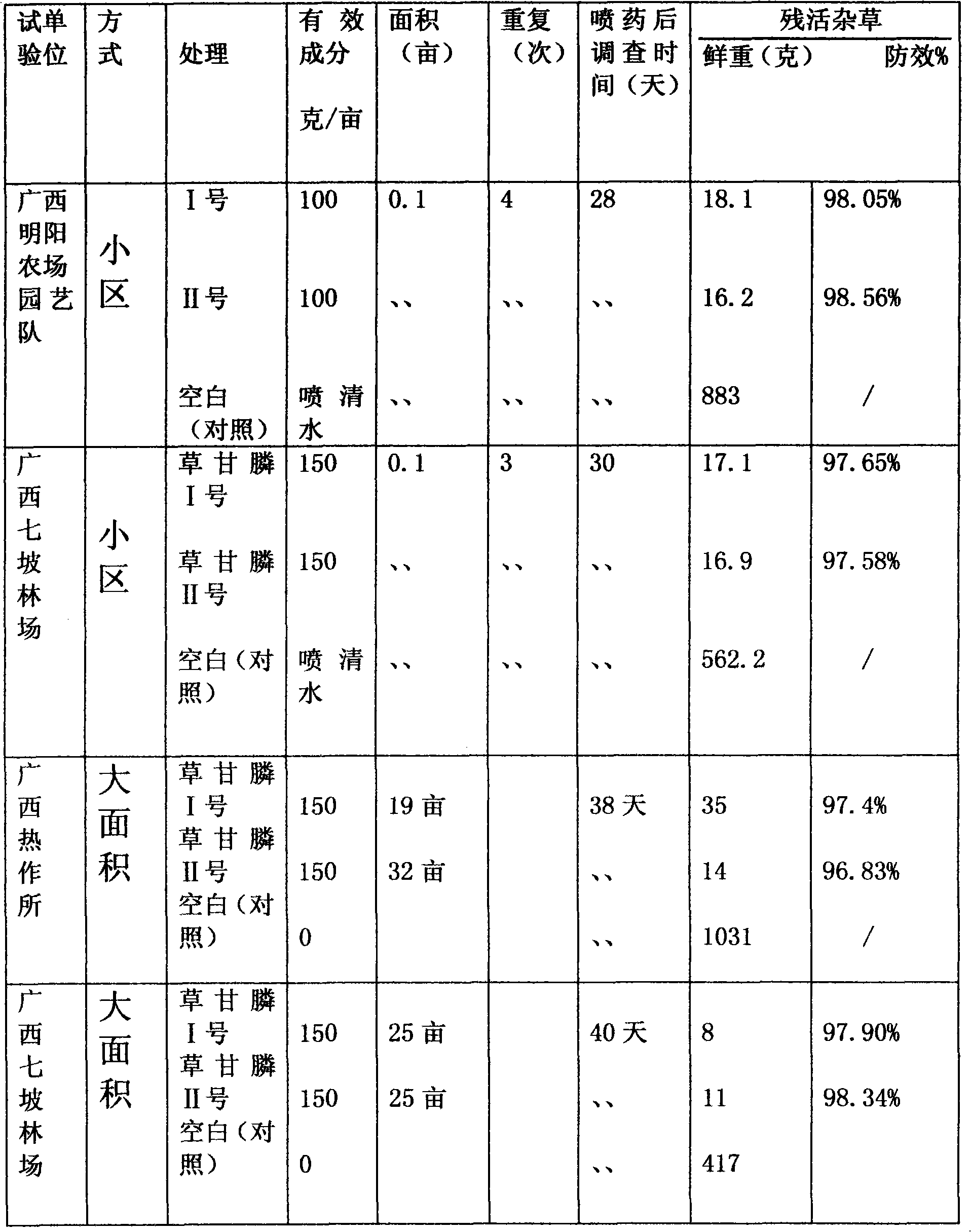

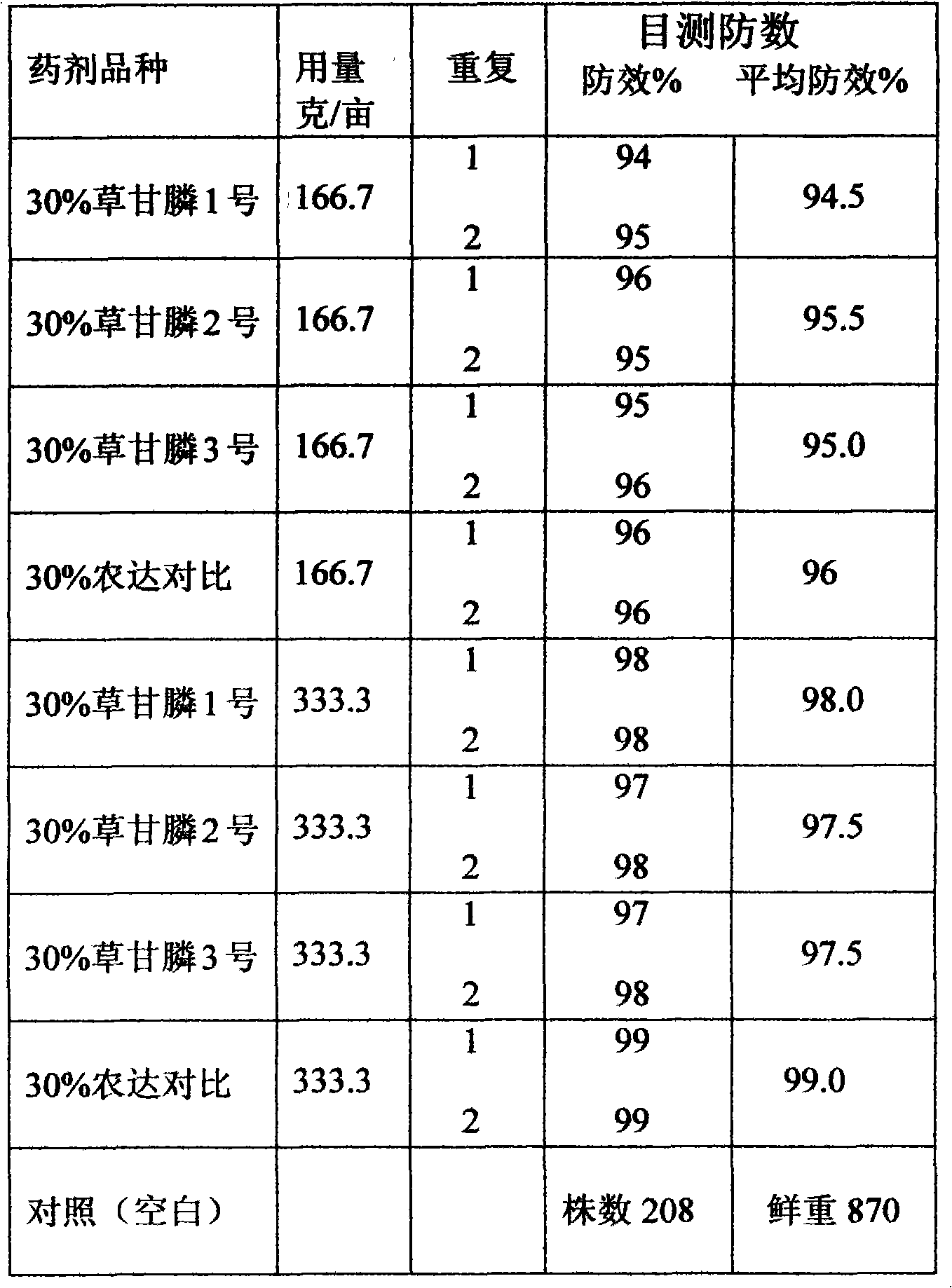

Examples

Embodiment 1

[0078] Put 320kg (1.797kmol) of glyphosate technical material with a purity of 95% into a 2000L reactor, add 200L of deionized water, and add 214kg (3.14kmol) of ammonia water with a concentration of 25% dropwise for about half the time while stirring. Hours, the temperature is controlled at 40C °-50C °, after the ammonia solution is added dropwise, it is incubated between 50C °-60C ° for one hour, and the pH value is controlled between 6.5-7.0 after the reaction is completed. Then add ammonium sulfate 50kg, glycine ethyl ester hydrochloride 40kg. Supplement the remaining amount of pigment-containing water, so that the preparation meets the requirement that N-phosphonic acid methylglycine accounts for 30% (weight) of the mass fraction. The product is packaged after precipitation to remove impurities. The product was 912kg (1.619kmol).

Embodiment 2

[0080] Put 320kg (1.797kmol) of glyphosate technical material with a purity of 95% into a 2000L reactor, add 250L of deionized water, and add 297.2kg (3.14kmol) of ammonia water with a concentration of 18% dropwise under stirring. The time is about For half an hour, the temperature was controlled at 30C°-45C°. After the ammonia solution was added dropwise, it was kept at 45C°-55C° for one hour. After the reaction, the pH value was controlled between 6.5-7.0. Then add ammonium sulfate 50kg, glycine ethyl ester hydrochloride 45kg. Supplement the remaining amount of pigment-containing water, so that the preparation meets the requirement that N-phosphonic acid methylglycine accounts for 30% (weight) of the mass fraction. The product is packaged after precipitation to remove impurities. 922kg (1.635kmol) of the product was obtained.

Embodiment 3

[0082] Put 320kg (1.797kmol) of glyphosate technical product with a purity of 95% into a 2000L reactor, add 240L of deionized water, and add 318kg (3.14kmol) of ammonia water with a concentration of 16.78% dropwise for about half the time while stirring Hours, the temperature is controlled at 35C°-55C°, after the ammonia solution is added dropwise, it is incubated between 55C°-65C° for one hour, and the pH value is controlled between 6.5-7.0 after the reaction is completed. Then add ammonium sulfate 45kg, glycine ethyl ester hydrochloride 50kg. Supplement the remaining amount of pigment-containing water, so that the preparation meets the requirement that N-phosphonic acid methylglycine accounts for 30% (weight) of the mass fraction. The product is packaged after precipitation to remove impurities. The product was 912kg (1.618kmol).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com