Circuit structure for on-board microwave transceiving modules and manufacturing method thereof

A technology of circuit structure and transceiver components, applied in the direction of assembling printed circuits with electrical components, printed circuits connected with non-printed electrical components, etc., can solve the problems of expensive components and high manufacturing costs, achieve performance problems and reduce manufacturing. The effect of cost, strong practicability and application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

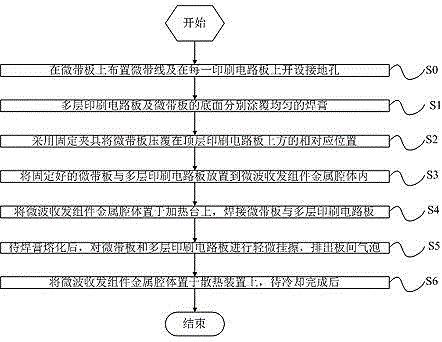

[0027] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

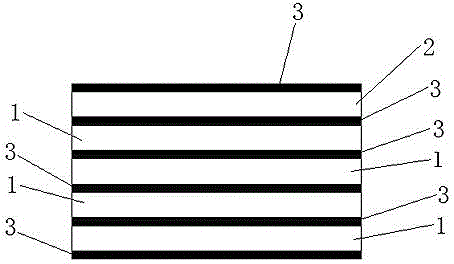

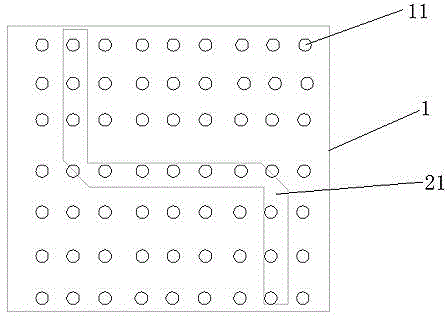

[0028] Design multilayer printed circuit boards by rationally allocating the power supply layer, control layer and ground layer, using the principle of electromagnetic compatibility and the principle of multilayer circuit processing and wiring; according to the microstrip line theory, carry out the design of the microstrip board (including the calculation of the impedance of the microstrip line and corner standing wave simulation), to solve the electromagnetic compatibility problems of multi-layer boards caused by the types of power supplies of missile-borne microwave transceiver components and the variety of high and low speed control lines. In a very small space, a highly integrated, miniaturized multi-layer printed circuit board circuit board design is realized.

[0029] Such as figure 1 and figure 2 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com