Carbon-serial conductive coating with ultralow content of carbon tubes and preparation method thereof

A conductive coating and ultra-low carbon technology, applied in conductive coatings, coatings and other directions, can solve the problems of poor decorative performance of pigments, complicated preparation methods, and high carbon tube content, and achieve strong decorative performance, improve decorative performance, and carbon tube content. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

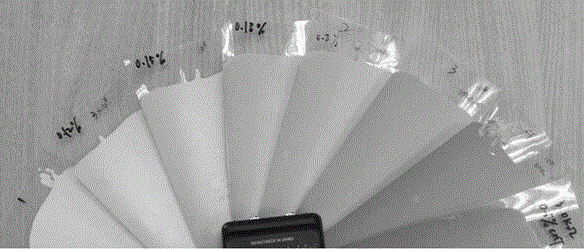

Image

Examples

preparation example Construction

[0028] A preparation method of the above-mentioned ultra-low carbon tube content carbon-based conductive coating, the preparation method comprises the following steps in turn:

[0029] Primary dispersion: firstly add the carbon nanotube array to the base paint, then perform primary dispersion with primary high-speed dispersion equipment with ball milling media to obtain a primary dispersion, and then use a filter to filter out the ball milling media in the primary dispersion to obtain intermediate mixing Coating, the mass percent concentration of carbon nanotubes in the intermediate mixed coating is 0.5-1.5wt%;

[0030] Secondary dispersion: first add the above intermediate mixed paint into the base paint, and then use a secondary high-speed dispersion equipment with ball milling media for secondary dispersion to obtain a secondary dispersion, and then use a filter to filter out the ball milling in the secondary dispersion medium to obtain the conductive coating, the mass perc...

Embodiment 1

[0047] A preparation method of ultra-low carbon tube content carbon-based conductive paint, said preparation method comprising the following steps in sequence:

[0048] Primary dispersion: Add 0.5g of carbon nanotube arrays to 100g of basic paint, and disperse with a primary high-speed dispersion device with ball milling media to obtain a primary dispersion. The speed of the dispersion device is 2000rpm, and the dispersion time is 2h. The ball milling medium in the primary dispersion is filtered by a net to obtain an intermediate mixed coating, and the mass percentage concentration of carbon nanotubes in the intermediate mixed coating is 0.5wt%;

[0049] Secondary dispersion: first mix the above-mentioned intermediate mixed paint with 400g of the base paint, and then carry out secondary dispersion with a secondary high-speed dispersion equipment with ball milling media to obtain a secondary dispersion, and then use a filter to filter out the secondary dispersion The medium is ...

Embodiment 2

[0052] The basic content is the same as in Example 1, the difference is that in the secondary dispersion, the intermediate mixed paint is mixed with 317g of the base paint, and the mass percentage concentration of carbon nanotubes in the finally obtained conductive paint is 0.12wt%, and the paint film after spraying The sheet resistance is 3×10 8 Ω.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com