Composite crucible

A composite crucible and crucible technology, applied in silicon compounds, crystal growth, inorganic chemistry, etc., can solve the problems of increasing safety hazards, cracking, and reducing the service life of graphite substrates, so as to improve the water cooling effect and reduce the possibility of carbon pollution , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

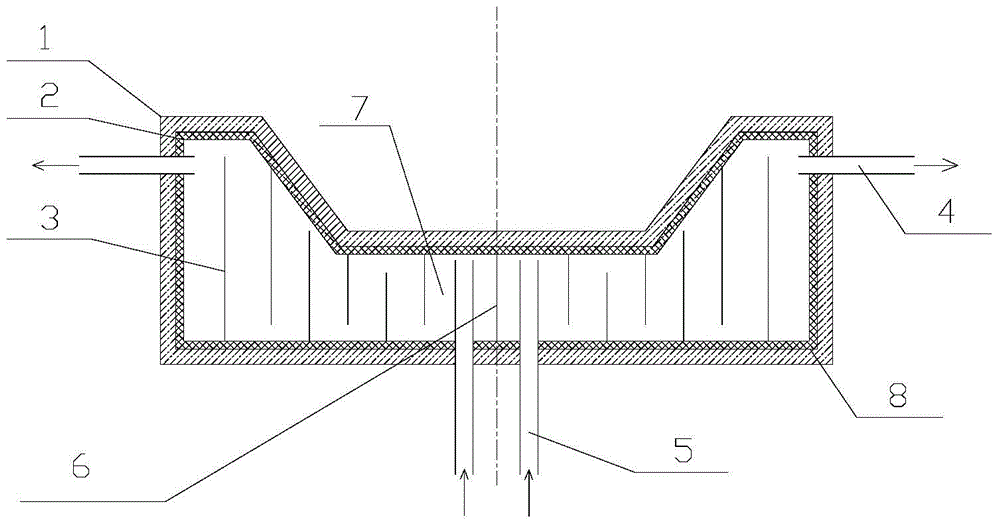

[0020] A composite crucible, the crucible includes a crucible body 8, the crucible body 8 is a cavity structure, and the inside is a cavity 7 for cooling liquid circulation; the upper surface of the crucible body 8 is a groove structure for To hold materials; the lower surface of the crucible body 8 is flat; the crucible body 8 is made of double-layer materials, wherein the outer layer is graphite and the inner layer is copper. Wherein the graphite layer and the copper layer are closely bonded, and the thickness of the graphite outer layer material is 25 mm; the thickness of the copper inner layer material is 10 mm.

[0021] The cavity 7 is provided with a partition 3 to reduce the flow velocity of the cooling liquid. The partitions 3 are fixed on the inner surface of the crucible body 8 , and the openings between the partitions 7 are facing and alternately staggered. The interval between the partitions is 15mm, the openings between the partitions are opposite and alternately...

Embodiment 2

[0024] A composite crucible, the crucible includes a crucible body 8, the crucible body 8 is a cavity structure, and the inside is a cavity 7 for cooling liquid circulation; the upper surface of the crucible body 8 is a groove structure for To hold materials; the lower surface of the crucible body 8 is flat; the crucible body 8 is made of double-layer materials, wherein the outer layer is graphite and the inner layer is copper. The graphite layer and the copper layer are closely bonded, and the thickness of the graphite outer layer material is 45mm; the thickness of the red copper inner layer material is 25mm.

[0025] The cavity 7 is provided with a partition 3 to reduce the flow velocity of the cooling liquid. The partitions 3 are fixed on the inner surface of the crucible body 8 , and the openings between the partitions 7 are facing and alternately staggered. The interval between the partitions is 35mm, the openings between the partitions are opposite and alternately stagg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com