Noiseless steel sheet pile pressing equipment and construction method thereof

A technology for piling equipment and steel sheet piles, which is applied to sheet pile walls, infrastructure engineering, construction, etc., and can solve the problems of high center of gravity, high noise, and large vibration of steel sheet pile drivers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

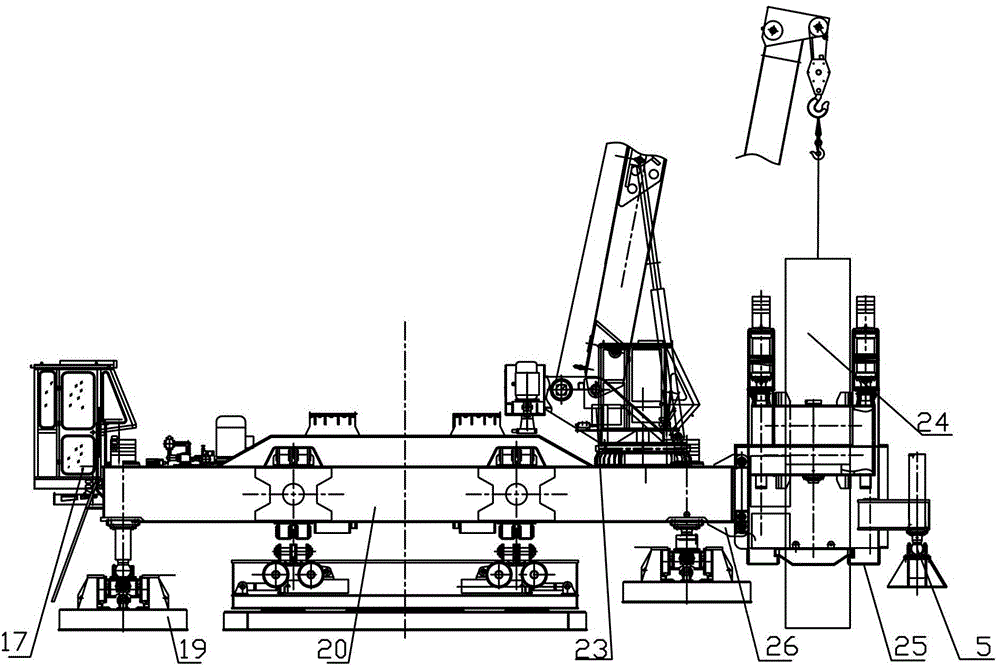

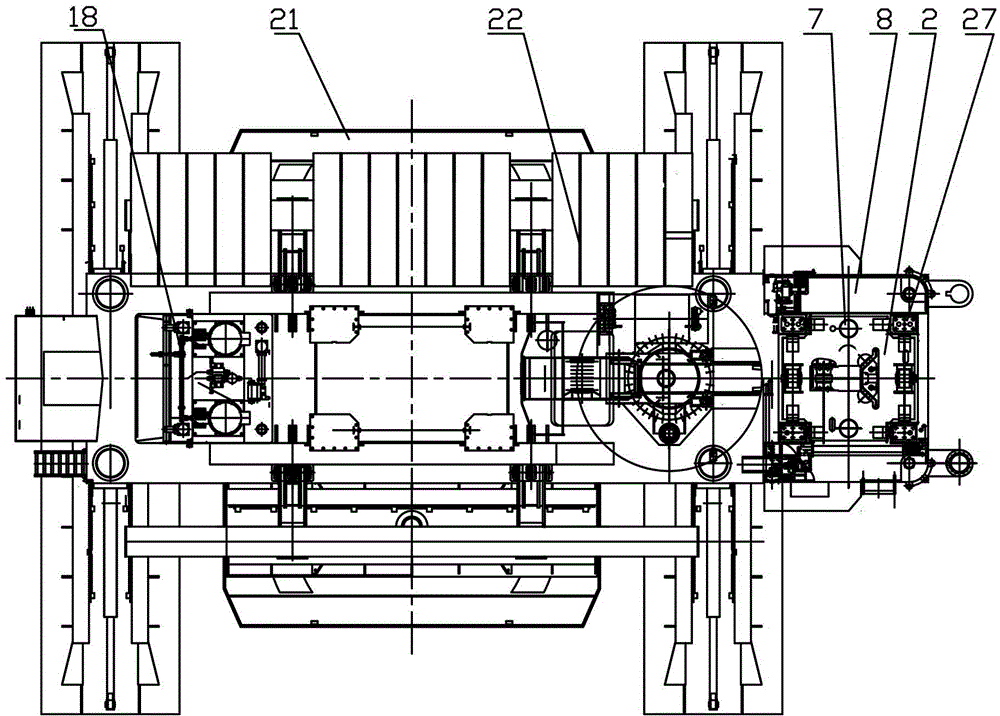

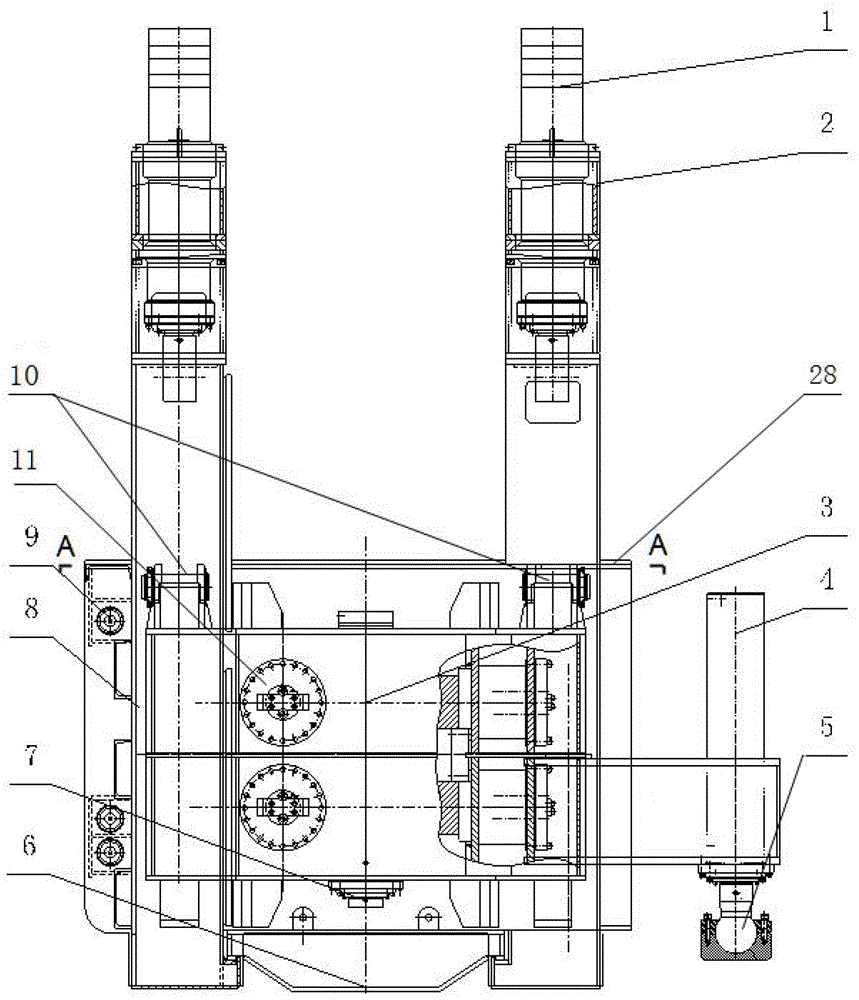

[0026] Below in conjunction with accompanying drawing, the present invention is further described: as figure 1 , 2 As shown in , the noiseless steel sheet pile pressing equipment includes an operating room 17, a long boat 19, a short boat, a short boat turning 21, a platform 20, a crane 23, an electrical control system, a hydraulic system and a pile pressing device 25, Such as image 3 , the pile pressing device 25 includes a gantry 2, a pile pressing cylinder 1, a clamping mechanism 3, a base 8, side pile legs 5, and side pile support cylinders 4, and the base 8 is connected to the side of the platform 20 through a pin The side pile hinge seats 26 are connected, the base 8 is fixedly connected to a pair of gantry 2 by bolts, and a pair of pile pressing cylinders 1 are fixedly installed in a pair of gantry respectively, and a pair of connecting hinges are arranged on both sides of the top of the clamping mechanism 3 Seat 10, the piston rod of pile-pressing cylinder 1 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com