Rapid detection equipment for ECU of electric vehicle

A technology for testing equipment and electric vehicles, applied in electrical testing/monitoring, testing/monitoring control systems, instruments, etc., can solve problems such as affecting testing efficiency, unfavorable rapid testing for enterprises, slow testing speed, etc. The effect of high detection and device detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

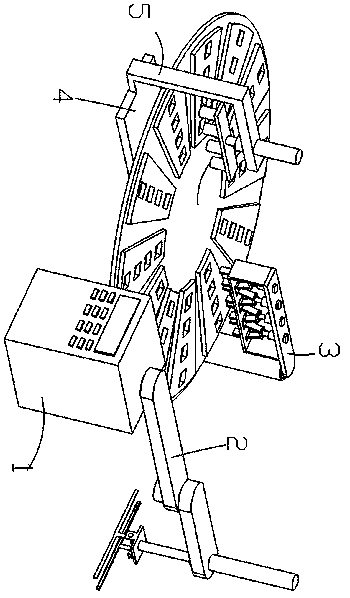

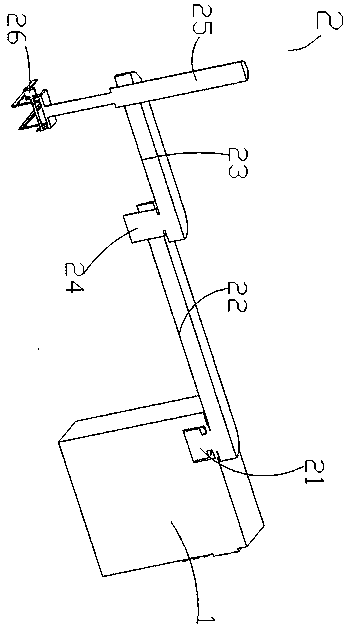

[0031] Such as figure 1 , 2As shown in and 4, a fast detection device for an electric vehicle ECU includes a control structure 1, a loading and unloading structure 2, a defective product rejecting structure 3, a rotating structure 4, and a detection structure 5. The top of the control structure 1 is provided with a loading and unloading structure 2, and the upper and lower The material structure 2 comprises a first rotating motor 21, a first rotating plate 22, a second rotating plate 23, a second rotating motor 24, a first electric push rod 25 and a long plate-shaped clamping structure 26, and the first rotating motor 21 is connected with The first rotating plate 22, the control structure 1 includes a control box and a control panel, the first rotating motor 21 is fixedly connected in the through hole at the top of the control box of the control structure 1, and the through hole at the top of the control box of the control structure 1 passes through the fixedly connected beari...

Embodiment 2

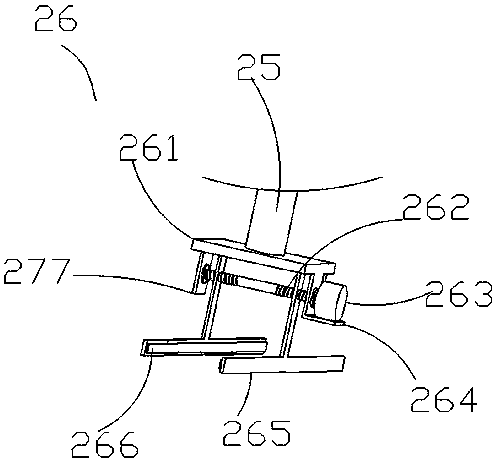

[0033] Such as image 3 As shown, the foundation of Embodiment 1 has been increased, and the long plate-shaped clamping structure 26 includes a horizontal plate 261, a threaded rod 262, a motor 263, a motor mounting plate 264, a T-shaped sliding clamping plate 265 and a straight plate 207, and the horizontal plate 261 and the first The telescopic rod of the electric push rod 25 is fixedly connected, and the bottom of the horizontal plate 261 is symmetrically fixedly connected with a straight plate 207, and the straight plate 207 is rotatably connected with a threaded rod 262 provided with threaded symmetry through a fixedly connected bearing, and the threaded rod 262 is connected with a T-shaped symmetrical thread. The sliding splint 265 and the inner wall of the T-shaped sliding splint 265 are fixedly connected with a rubber plate 266. By designing the rubber plate 266 on the T-shaped sliding splint 265, the rubber plate 266 increases the friction to ensure the clamping stabil...

Embodiment 3

[0035] Such as figure 1 , 4 , 5 and 6, the basis of embodiment 1 has been increased, and the rotating structure 4 includes a base plate 41, a straight cylinder 42 is fixedly connected to the middle end of the top of the base plate 41, and a fourth rotating motor 43 is fixedly connected to the bottom of the straight cylinder 42, and the fourth rotating motor The output end of 43 is fixedly connected with a turntable 44, the bottom of the turntable 44 is fixedly connected with the bearing fixedly connected with the top of the straight tube 42, and the turntable 44 is uniformly fixedly connected with a fan-shaped plate 46 along the circumferential direction, and the fan-shaped plate 46 is evenly provided with placement holes 45 , the depth of the placement hole 45 is 3-5mm; the front and rear sections of the bottom plate 41 are respectively provided with a defective product rejection structure 3 and a detection structure 5, and the detection structure 5 includes an L-shaped plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com