Ultra-shallow buried tunnel cover-excavation construction method

A construction method and tunnel technology are applied in the field of tunnel excavation construction and super-shallow buried tunnel cover excavation construction to achieve the effect of shortening road time, avoiding the risk of third-party loss and avoiding the risk of collapse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with embodiment and accompanying drawing: and present embodiment can not be used for limiting the present invention:

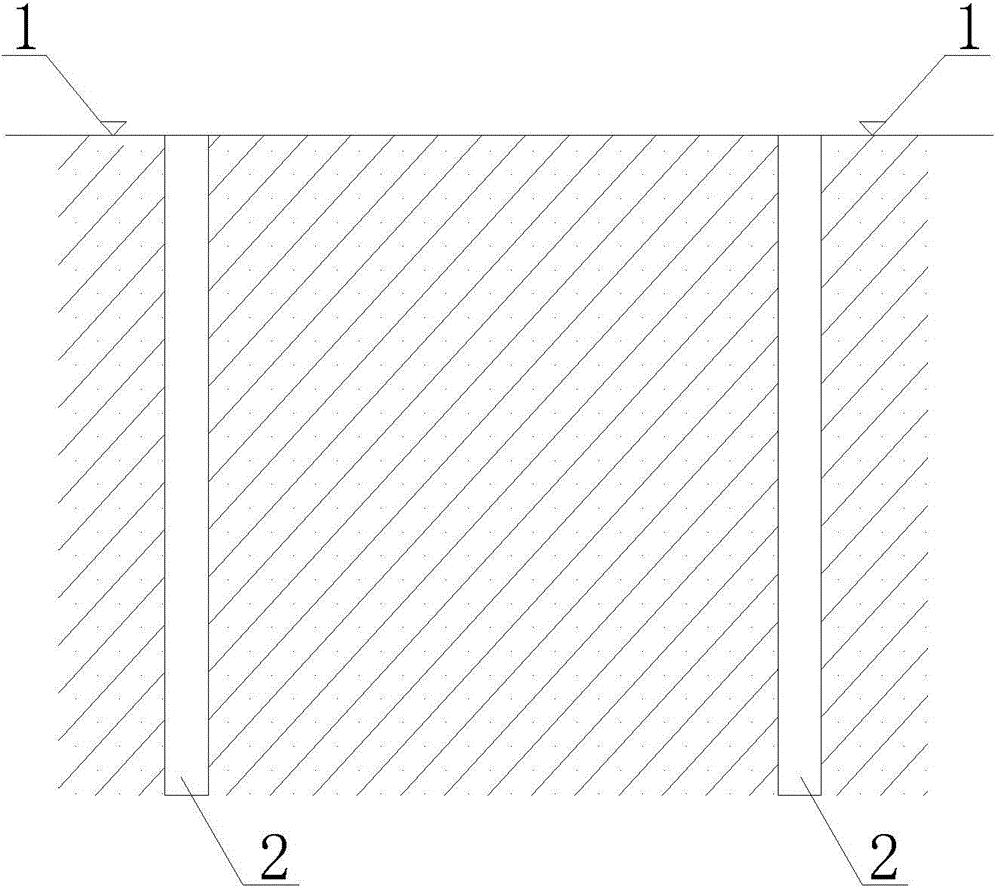

[0022] a. Ease road traffic; do a good job of ground (1) enclosure, close the proposed construction area, and minimize the impact on road traffic and the environment;

[0023] b. Carry out the surrounding protection pile (2) operation on both sides of the underground project to be implemented; according to the geological conditions, the surrounding protection pile (2) adopts rotary drilling or manual digging operation, and pours pile foundation concrete;

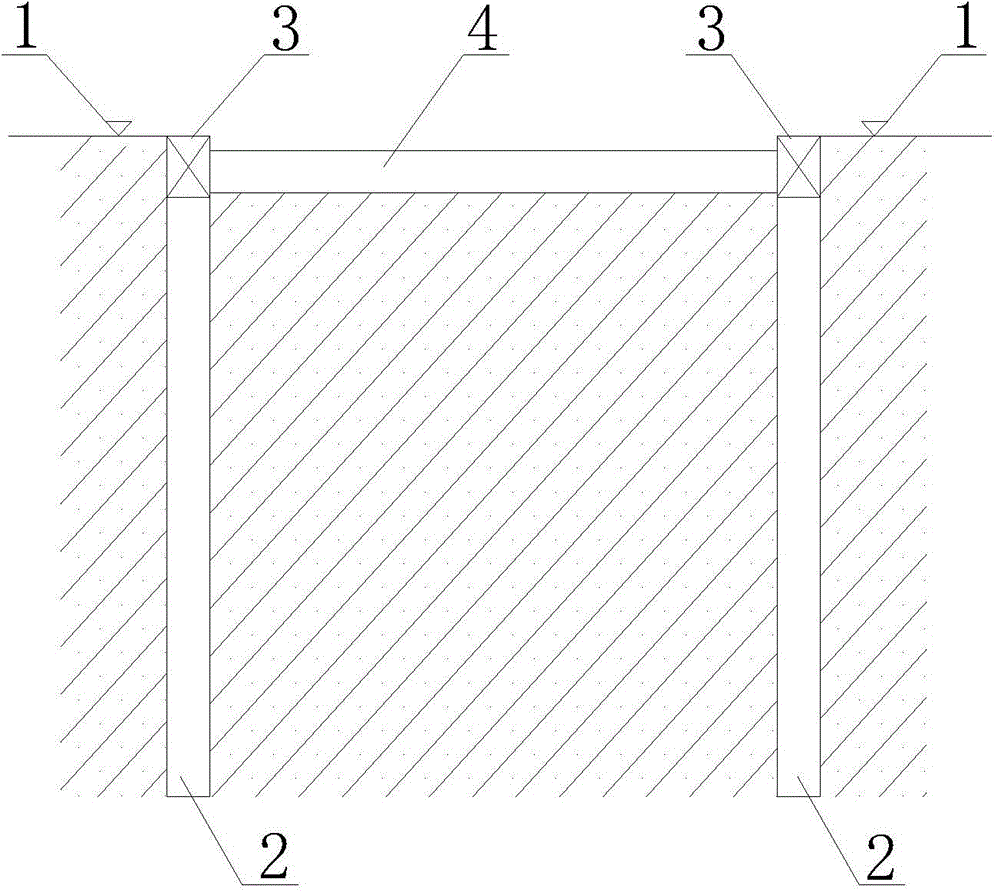

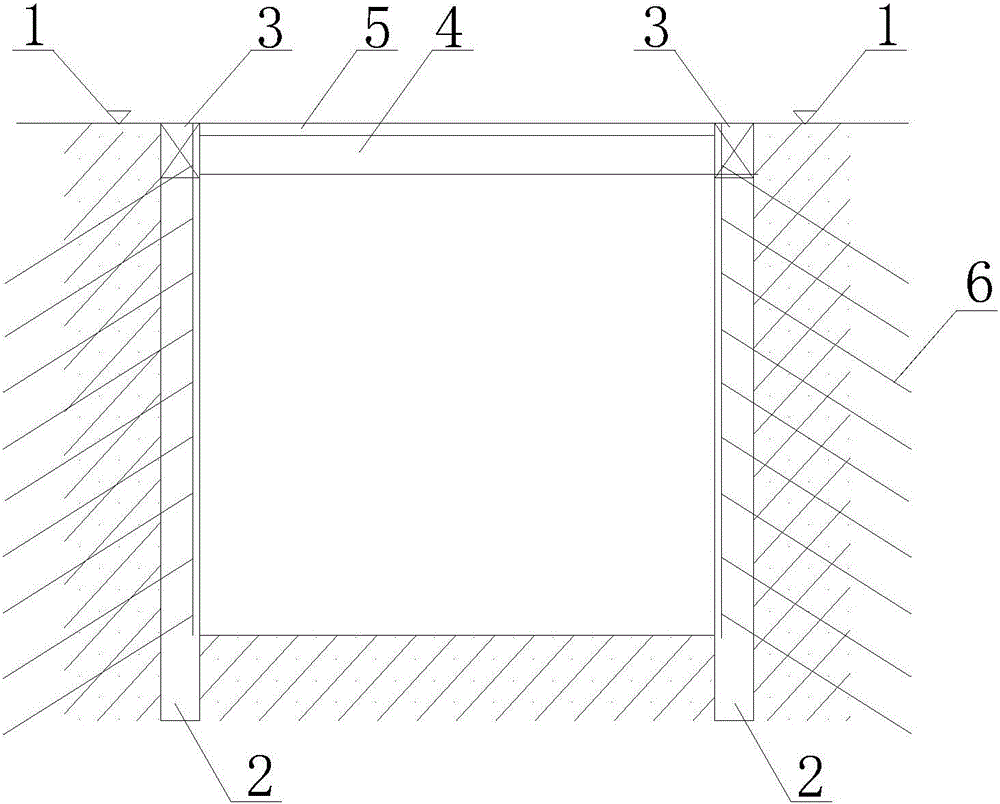

[0024] c. Construction of transverse load-bearing beams (4) and longitudinal load-bearing beams (3) and structural roof (5) on the top of the pile foundation: after the pile foundation concrete reaches the design strength, excavate the horizontal load-bearing beams (4) and longitudinal load-bearing beams Beam (3) foundation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com