Simple vinyl tile paving method

A floor and paving technology, applied in the direction of floor, building, building structure, etc., can solve the problems of bulging, blistering, long construction time, etc., to prevent bulging, better moisture-proof performance, Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

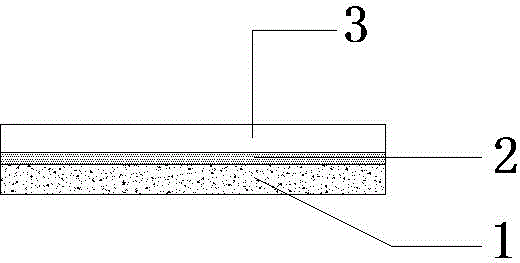

[0017] Combine below figure 1 , the present invention is described in detail:

[0018] A simple method for laying and pasting rubber flooring. The specific operation process includes: mixing exterior wall putty powder, water, and white latex in a ratio of 2.5:1:0.5, stirring evenly to form exterior wall putty 1 with a thick paste texture, and mixing it evenly Apply it on the ground where the rubber floor needs to be laid. After scraping it with a scraper, use an industrial electric blower to blow the ground coated with exterior wall putty until it is half dry. Use a spatula to level the uneven exterior wall putty and continue Blow dry with a blower fan. After leveling the putty on the exterior wall, sand it with sandpaper until it is smooth and straight, and clean off the dust from the putty. Spread the glue floor 3 evenly on the water-based environmental protection special glue 2, and spread it horizontally on the exterior wall putty 1.

[0019] The description is not a li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com