Water pump bearing

A bearing and water pump technology, applied in the field of water pump bearings, can solve the problems of high bearing failure rate, short life and low bearing capacity, and achieve the effects of large bearing capacity, good rigidity and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

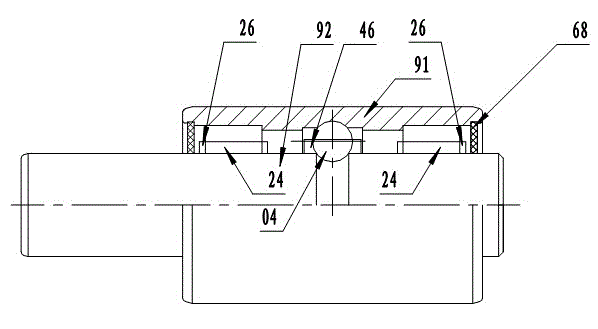

[0010] The specific embodiments of the present invention are given below with reference to the accompanying drawings, which are used to further describe the composition of the present invention in detail.

[0011] The water pump bearing of this embodiment includes an outer ring 91, a mandrel 92, a double-lip sealing ring 68, a ball retainer 46, a column retainer 26, a roller 24 and a steel ball 4, and the roller 24 is installed on the column retainer 26. In the window hole, the steel ball 4 is installed in the pocket of the ball cage 46, the outer ring 91 and the mandrel 92 are processed with grooves and raceways, the steel ball 4 rolls in the groove, and the roller 24 rolls on the raceway. The outer diameter of the double-lip sealing ring 68 is installed in the groove of the sealing ring of the outer ring 91, and the inner diameter of the double-lip sealing ring 68 is connected with the mandrel 92, and the double-lip sealing ring 68 is made of NBR.

[0012] The role of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com