Lever centrifugal clutch

A centrifugal clutch and lever technology, applied in the field of clutches, can solve the problems of damage to performance and service life, high material requirements, and difficult processing, and achieve the effects of simple structure, simplified processing, and reduced maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

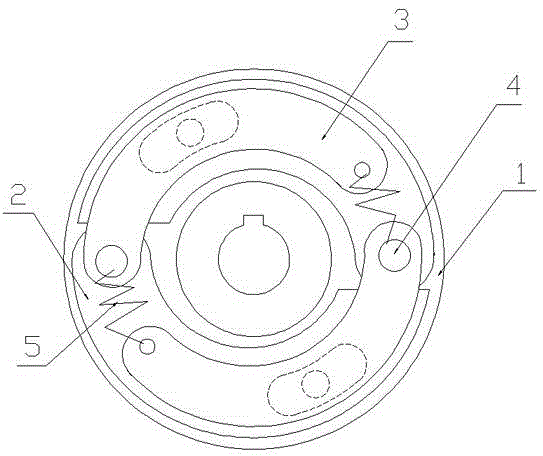

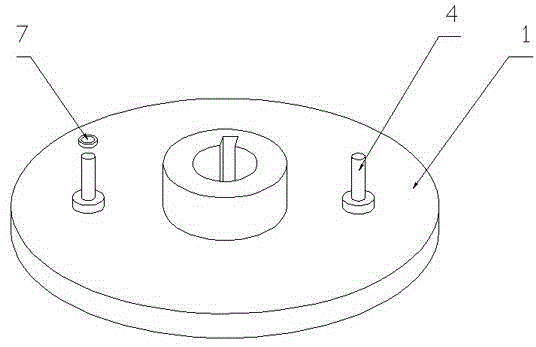

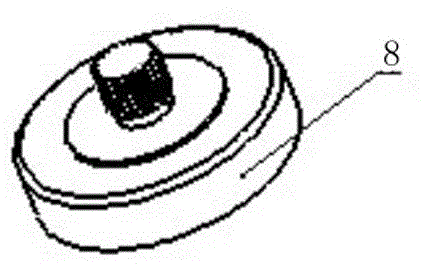

[0028] Such as Figure 1-Figure 7 A lever centrifugal clutch shown is provided with two or more positioning columns on the surface of the driving disc 1, the roots of the positioning columns 4 are all provided with steps, and the centrifugal body 2 of a group of centrifugal mechanisms One end of the centrifuge is movably socketed on the positioning column 4, and the other movable end of the centrifugal body 2 is provided with a protruding body A201 near the middle position; the corresponding special-shaped lever 3 is provided with a recessed groove A301, and the protruding body A201 enters the inside of the concave groove A301 of the special-shaped lever 3 . One end of the special-shaped lever 3 of the adjacent group of centrifugal mechanisms is movably socketed on the positioning column 4 and located on the centrifugal body 2. When the centrifugal force of the special-shaped lever 3 is greater than the tension of the tension spring 5, it passes through the side wall of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com