Longitudinal shaft type planetary friction mechanical stepless speed changer and gear ring

A transmission and transmission housing technology, applied in the transmission field, can solve the problems of small transmission range, high cost, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The content of the present invention will be explained by examples below. This example is only to illustrate the implementation of the present invention, and is not intended to limit the present invention. It should be noted that in the following examples and figures, elements not directly related to the present invention have been omitted, and the dimensions of the elements in the figures are only for easy understanding, and are not used to limit the actual scale.

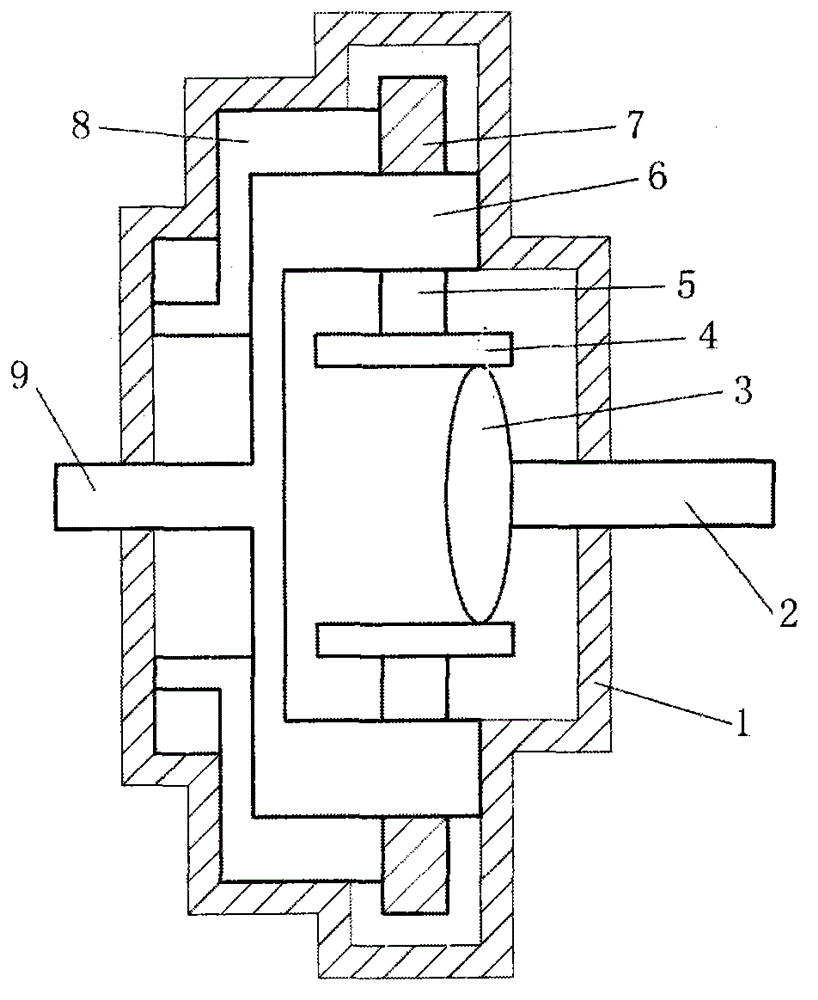

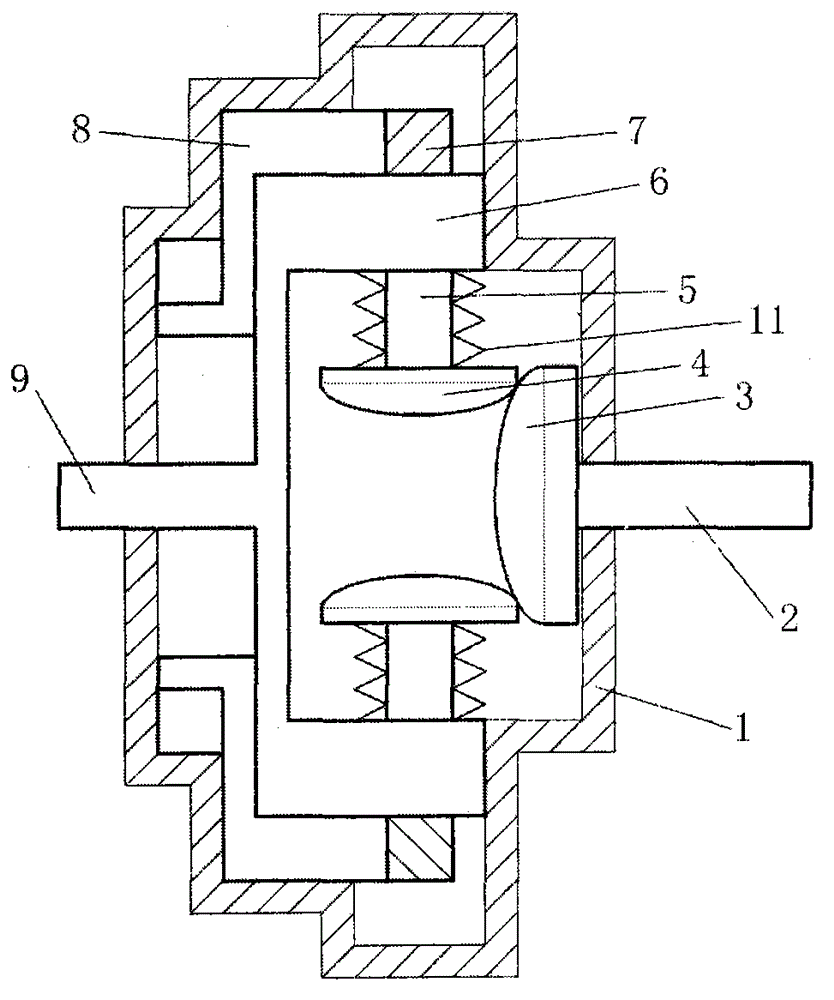

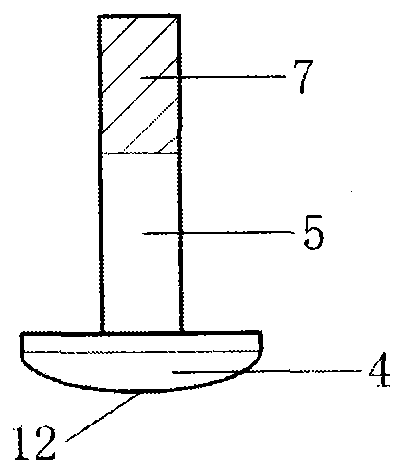

[0027] The transmission is realized in the following way: it includes sun friction wheel (3), planetary friction wheel (4), planetary shaft (5), planetary carrier (6), outer planetary wheel (7), ring gear (8), input shaft (2) Connected with the sun friction wheel (3), the sun friction wheel (3) can move axially, the sun friction wheel (3) is in contact with the planetary friction wheel (4), and the planetary friction wheel (4) passes through the planetary shaft (5) It is connected with the outer planetary g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com