Harmonic reducer gear with beta type gear shape and machining method thereof

A harmonic reducer, tooth shape technology, applied in the direction of components with teeth, belts/chains/gears, portable lifting devices, etc., can solve the problem of low bearing capacity, achieve good rigidity, good conjugate performance, and smooth running smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0023] The invention provides a harmonic reducer gear with a β-shaped tooth shape, including a flexible spline and a rigid spline. Both the flexible spline and the rigid spline have a β-shaped tooth shape.

[0024] Processing method of the present invention is:

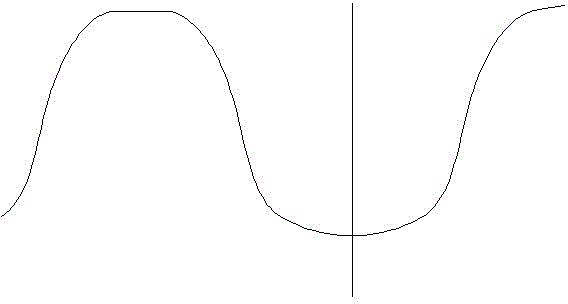

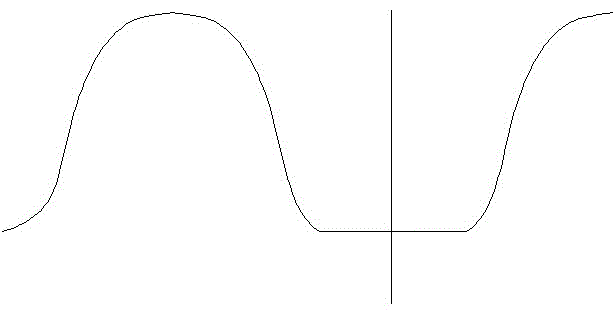

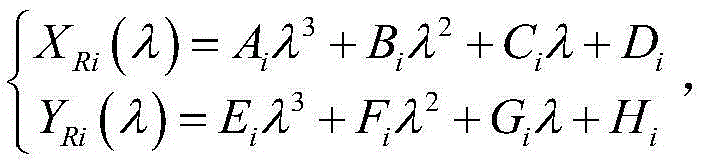

[0025] (1) Determine the tooth profile curve of the flexspline: determine the initial modulus of the flexspline according to the selected harmonic reducer, its transmission ratio and the inner diameter of the flexspline; then form a continuous spline according to the selected spline curve Tooth profile curve, as the tooth profile curve of a flexspline, such as figure 1 shown;

[0026] (2) Obtain the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com