Graphite rupture disk with groove

A bursting disc and graphite technology, applied in functional valve types, safety valves, engine components, etc., can solve the problems of bursting shape, rupture disc deformation, irregularity, etc., and achieve the effect of less debris, stable bursting pressure, and easy processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

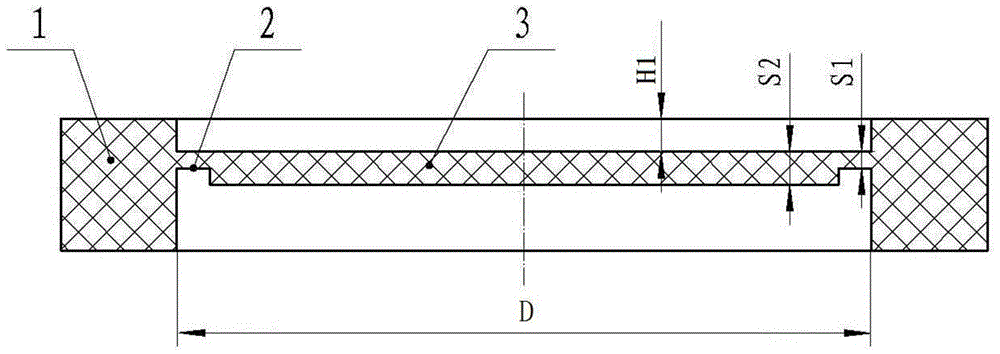

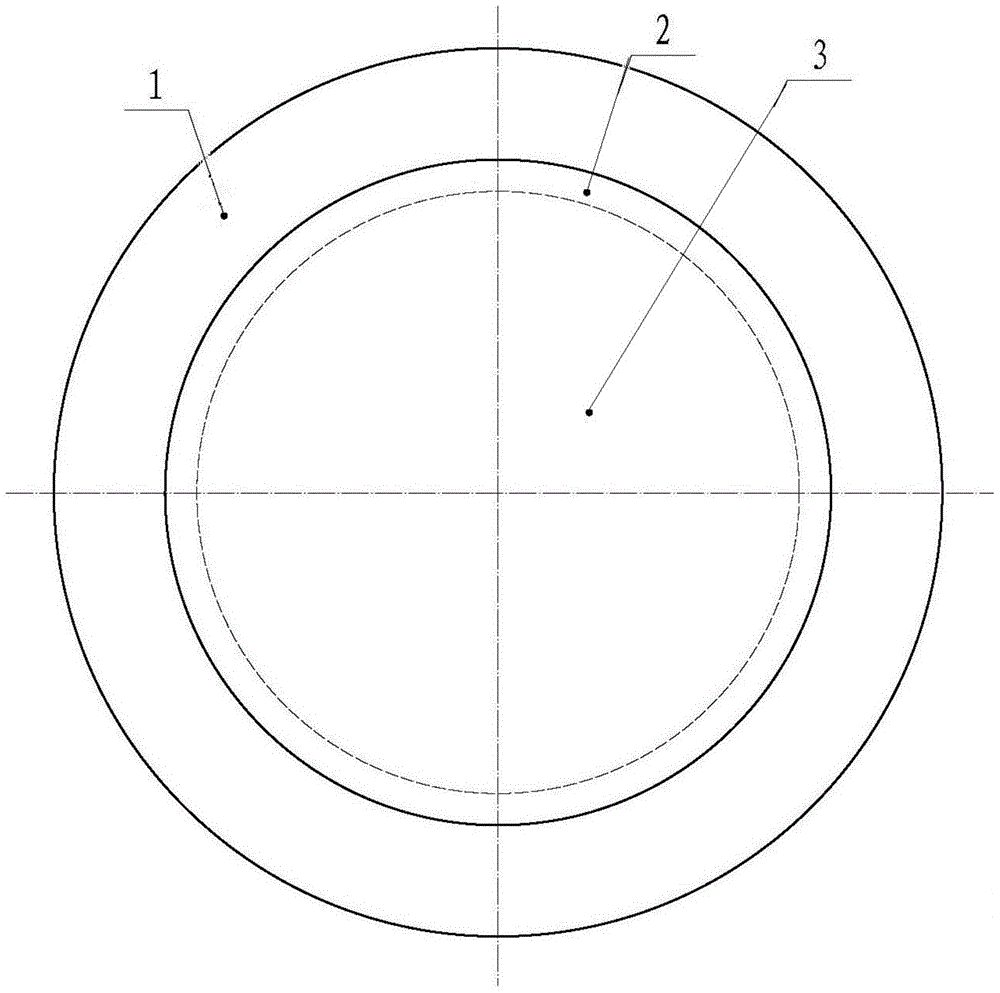

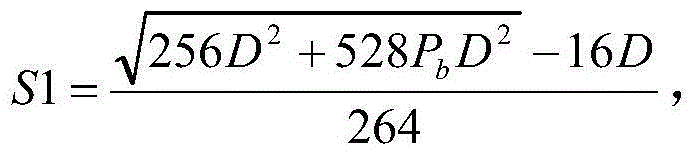

[0030] The nominal diameter of the grooved graphite rupture disc is DN=100mm, and the design burst pressure is P b =0.4MPa(G), the design burst temperature is 20°C, the height difference H1 between the upper surface of the bursting zone 3 of the bursting disc and the upper surface of the edge 1 of the bursting disc is 10mm, and the outer diameter of the annular connection part 2 D=110mm, the difference between the outer diameter and the inner diameter of the annular connection part 2 is 5mm, calculated according to the following formula:

[0031] S 1 = 256 D 2 + 528 P b D 2 - 16 D 264 ,

[0032] The thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com