Cable penetration sealing device and production method thereof

A sealing device and cable technology, which is applied in the direction of pipes, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems that the cable penetration sealing structure cannot be unified, the sealing method is rigid, and mass production cannot be achieved, so as to achieve excellent electrical insulation and The effects of radiation resistance, simple structure and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

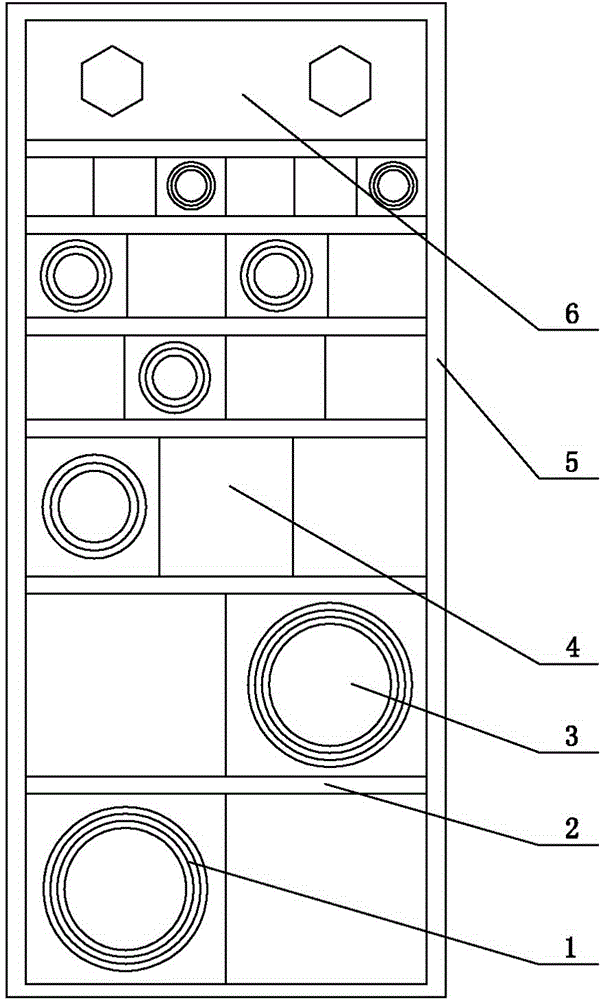

[0012] The present invention includes a frame body 4, in which a sealing module 1 with a through hole 3 is layered, and a partition 2 is arranged between layers; The gap between them is filled by the blind plugging module 4; a pressing block 6 is arranged above the uppermost partition 2.

[0013] As a preferred solution: the sealing module 1 is made of 1,4-hexadiene electrically insulating EPDM glue.

[0014] The 1,4-hexadiene type electrical insulating EPDM rubber is an existing material available in the market.

[0015] The 1,4-hexadiene-type electrical insulation EPDM rubber of the present invention can also be added with aluminum hydroxide and magnesium hydroxide-based inorganic flame retardants; it has low toxicity, low smoke, non-volatile, No corrosive gas and other advantages.

[0016] Preparation method of the present invention.

[0017] First, the sealing module 1 and the cable are installed layer by layer in the frame body 4, and a partition 2 is set b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com