Glue injection joint accessory for large-diameter composite hose

A composite hose and large-diameter technology, applied in the direction of pipes/pipe joints/fittings, hose connection devices, mechanical equipment, etc., can solve the problems of loss of sealing performance, joint falling off, high cost, etc., to reduce the possibility of penetration, Guaranteed strength and tightness, and the effect of preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

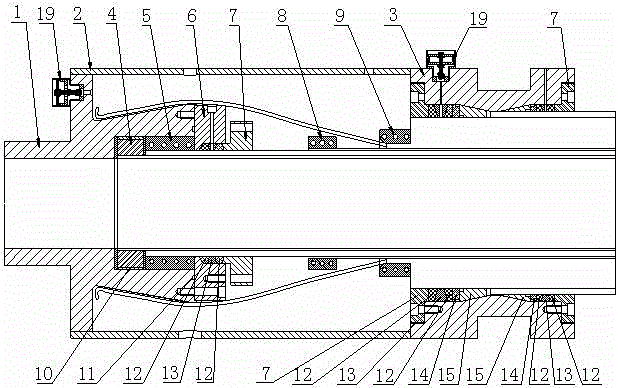

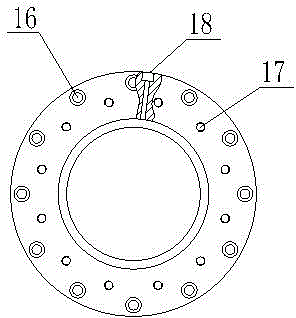

[0019] Such as figure 1 , 2 As shown, the present invention includes a joint front end 1, a joint jacket 2, a joint rear end 3, a fixing ring 4, a fixing sleeve 5, a fastening flange 6, a sealing flange 7, a tight sleeve 8, a clamping block 9, and an insulating pad 10. O-ring 11, sealing ring 12, steel ring 13, steel sleeve 14 and tapered sleeve 15. Put the sealing flange 7, sealing ring 12, steel ring 13, sealing ring 12, steel sleeve 14, tapered sleeve 15, and joint rear end 3 into the outer cladding layer of the composite hose in sequence, and pass the high-strength bolts through the sealing method Screw the through hole of flange 7 into the threaded hole 3 at the rear end of the joint, and the sealing ring 12 is deformed to achieve sealing; the tapered sleeve 15, steel sleeve 14, sealing ring 12, steel ring 13, sealing ring 12, and sealing flan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com