Boiler and sterilizing device with same

A technology for boilers and sterilizing tanks, which is applied in the field of boilers and sterilizing devices equipped with the boilers, which can solve the problems of a large amount of white garbage and environmental pollution, and achieve good environmental protection effects, good sterilization effects, and low infection rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

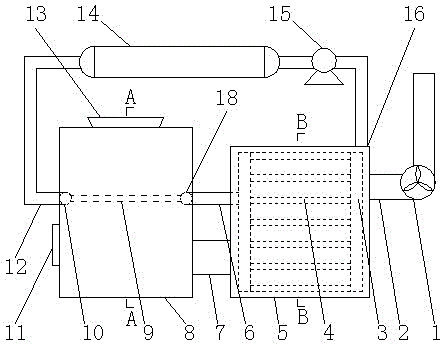

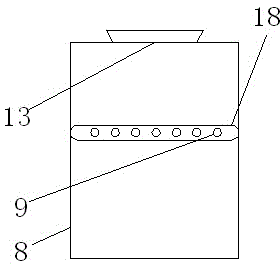

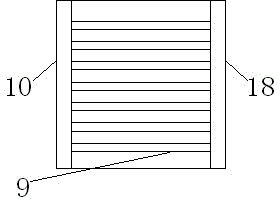

[0017] The present invention is described in further detail in conjunction with accompanying drawing, a kind of boiler comprises furnace body 8, furnace 17, outlet pipe 6, water return pipe 12, is provided with furnace bridge in furnace 17, and described furnace bridge is pipeline, and this pipeline two ends and The water outlet pipe 6 and the water return pipe 12 are connected; the furnace body 8 is provided with a feed inlet 13, and the furnace body wall below the furnace bridge is provided with a slag discharge door 11.

[0018] In order to enable the furnace bridge to fully absorb the heat generated by fuel combustion, there are connecting pipes on both sides of the furnace bridge. The connecting pipes are connected together through several branch pipes 9, and the return pipe 12 communicates with the connecting pipe 10 on the left side of the furnace bridge. , Outlet pipe 6 communicates with connecting pipe 18 on the right side of the furnace bridge.

[0019] In order to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com