Ceramic spray drying tower

A spray drying tower and ceramic technology, which is applied in the direction of drying solid materials, drying, dryers, etc., can solve the problems of affecting the discharge speed of materials, increasing the draft of induced draft fans, and wasting energy by heat energy, so as to improve the drying effect, The effect of reducing powder particles and improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further understand and recognize the structure, features and effects of the present invention, a preferred embodiment is now given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

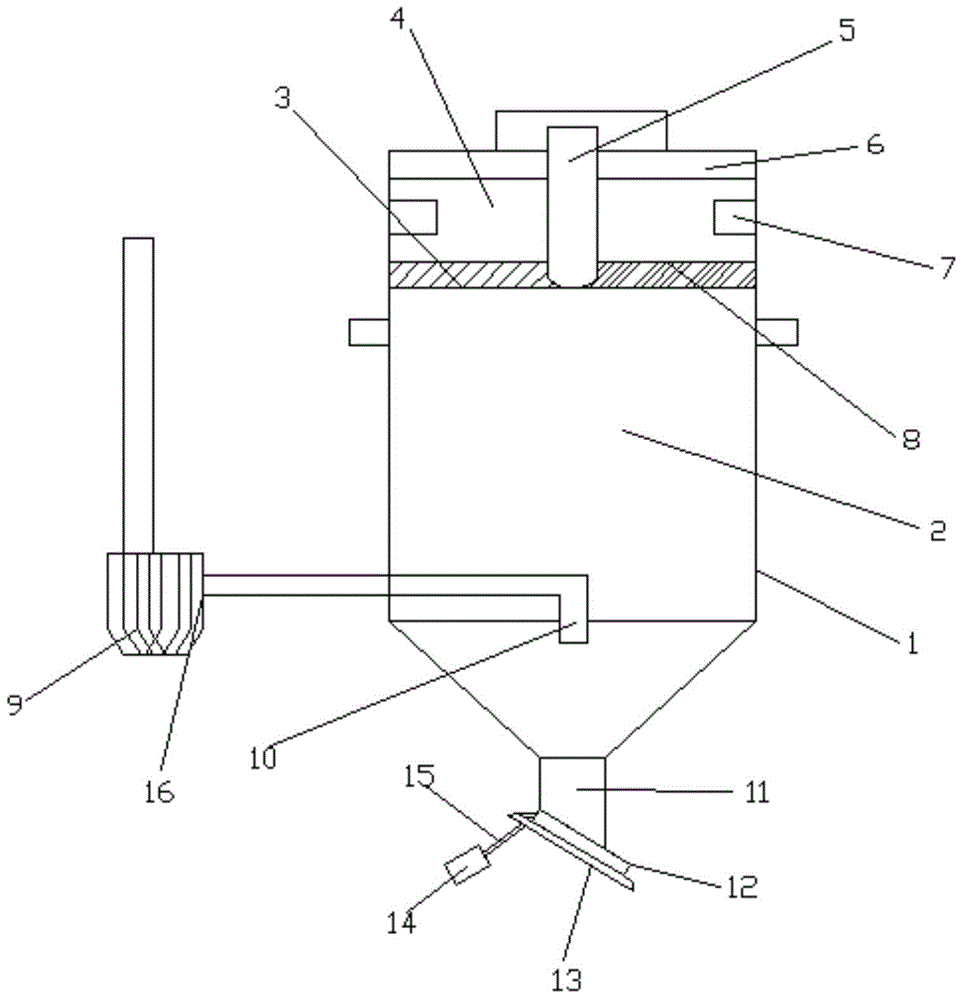

[0012] Such as figure 1 As shown, a ceramic spray drying tower described in this embodiment mainly includes a tower body 1, a discharge pipe 11 and a water atomization pipe 9, the discharge pipe 11 is arranged below the tower body 1, and above the tower body 1 A sealing cover 6 is provided, and a material sprayer 5 protruding into the tower body 1 stabilizing chamber 4 is provided in the middle, an air inlet 7 is provided on the wall of the stabilizing chamber 4, and an air hole 3 and an air inlet plate 8 are arranged below, and the air hole 3 is provided with a drying chamber 2 below, and the water atomizing pipe 9 is provided with a suction pipe 10 extending into the drying chamber 2 through the pipe body. A dust collector 16 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com