Sample chamber of sample analysis device

A technology of sample analysis and sample chamber, which is applied in the direction of measuring devices, analyzing materials, and material analysis through optical means, can solve the problems of increasing maintenance difficulty and workload, limited space, and increasing processing costs, and achieves installation and maintenance. High maintenance and reset accuracy, convenient cleaning, and consistent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

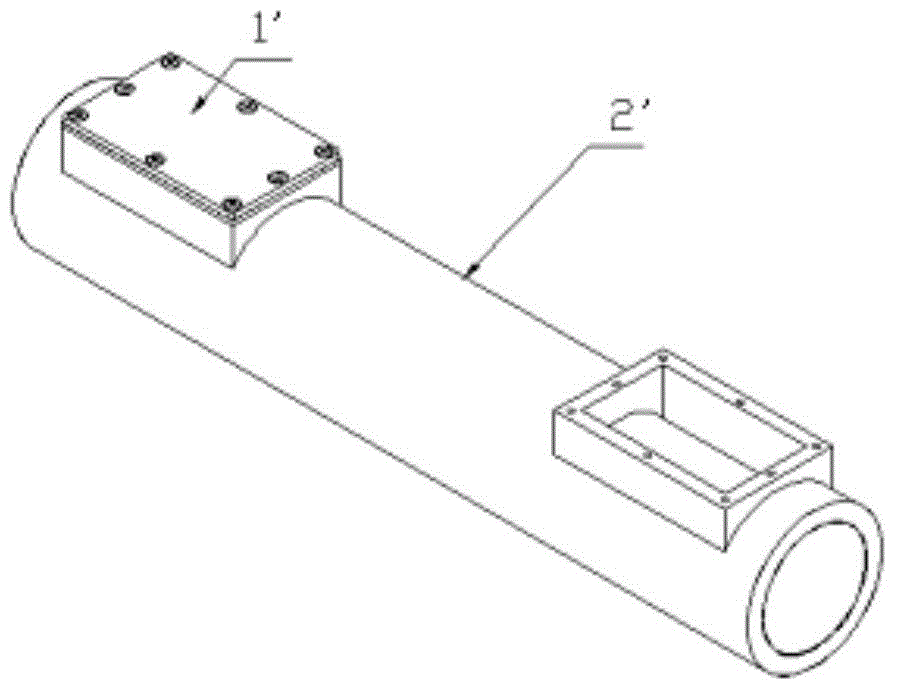

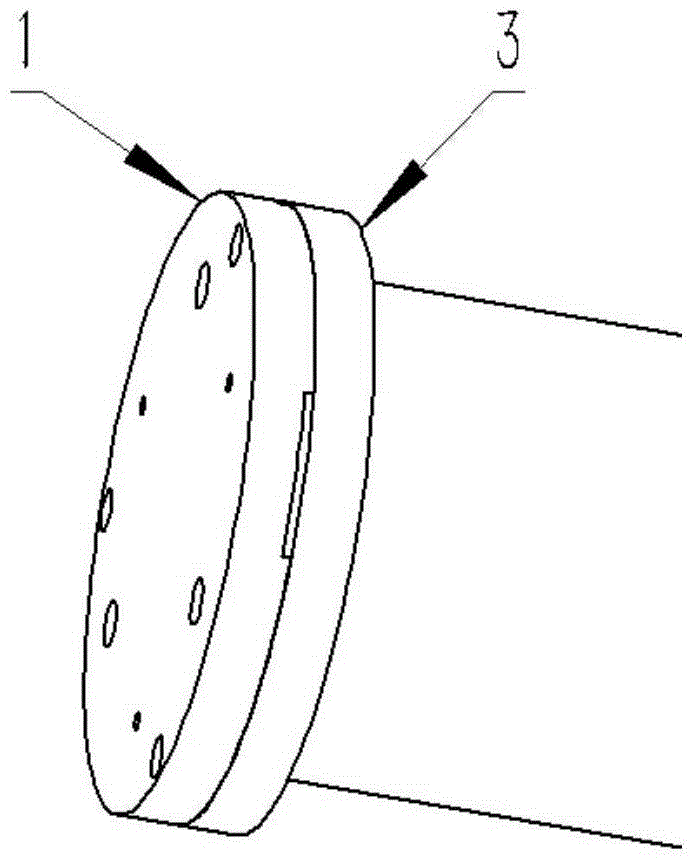

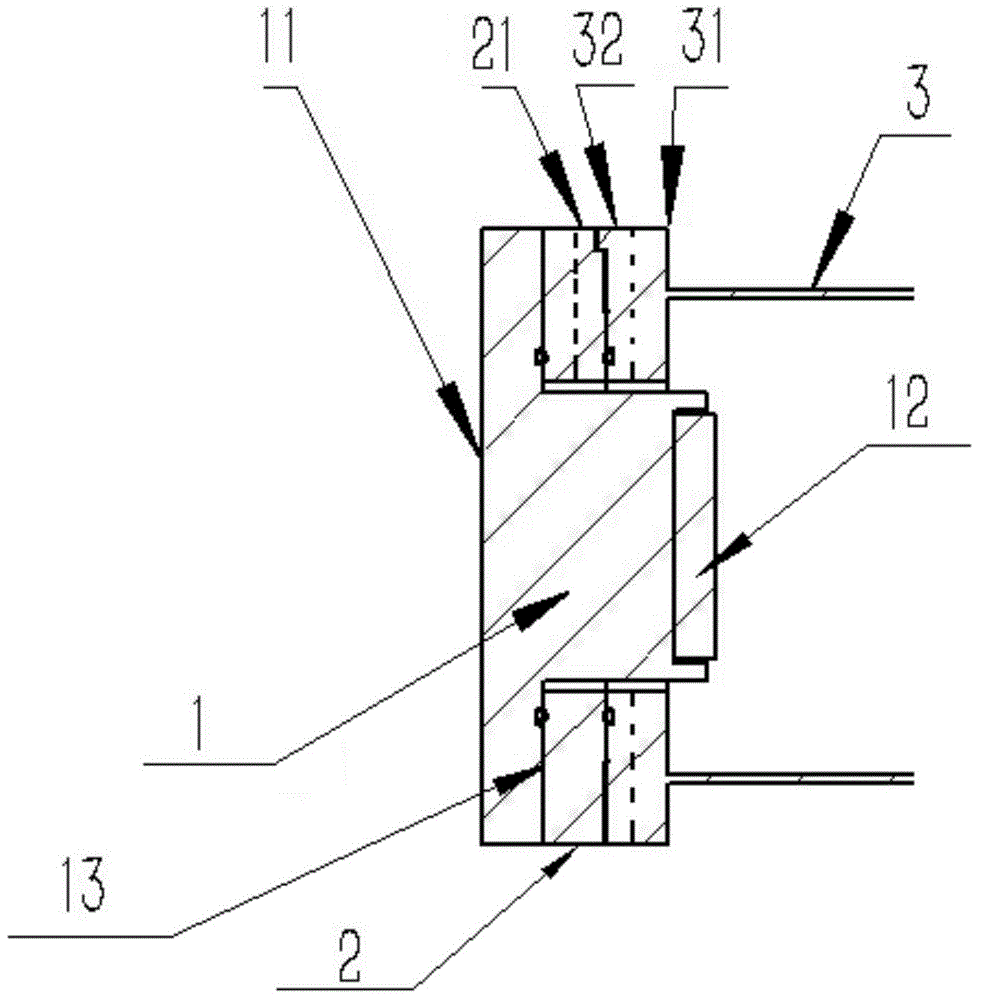

[0036] The optical components in the sample analyzer are easily contaminated by impurities in the sample during use. The existing cleaning method is to clean the optical components on the basis of disassembly and by opening a maintenance window on the wall of the sample chamber, but this method Due to the space and angle limitations of the maintenance window, there are dead angles for observation and cleaning, and the cleaning of the optical components is not thorough enough; if the optical components are disassembled and cleaned, there is no guarantee that the optical components can return to their original positions without the operation of professionals. In view of the above problems, the present invention discloses a sample chamber of a sample analysis device that can thoroughly clean the optical element and allow the optical element to be accurately assembled.

[0037] The technical solutions of the present invention will be further described in detail below through embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com