Method for determining separation size of hydrocyclone

A hydrocyclone and particle size separation technology, which is applied in the field of determining the separation particle size of hydrocyclones and grading hydrocyclones in mineral processing, can solve the problems of poor accuracy and breadth of use, improve accuracy, save manpower and material resources, Effects of Applicability and Reliability Enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

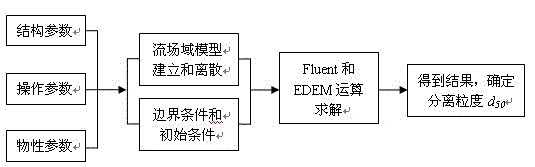

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

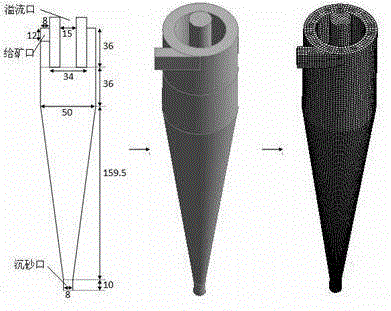

[0022] The application effect of the present invention will be illustrated below through examples of separating quartz and hematite particles by a Φ50mm hydrocyclone.

[0023] 1. Determine the parameter conditions (including structural parameters and operating parameters) of the hydrocyclone as shown in Table 1.

[0024] Table 1 Parameter list of Φ50mm hydrocyclone

[0025]

[0026] 2. Determine the operating parameters of the target working condition: the ore feeding pressure is 0.1MPa, and the ore feeding concentration is 10%.

[0027] 3. Determine the physical parameters of the material to be separated: the separation medium is water, and the air column of the hydrocyclone is considered. The density of water is 998.2kg / m 3 , the dynamic viscosity is 1.003×10 -3 Pa s; the density of air is 1.225kg / m 3 , the dynamic viscosity is 1.7894×10 -5 Pa s; the density of quartz is 2673kg / m 3 ; The density of hematite is 4858kg / m 3 ; The particle size composition of quart...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com