Water resistance rowing machine

A rowing machine and water resistance technology, applied in simulators, instruments, space navigation equipment, etc., can solve the problems of increasing consumption, increasing the burden on rowers, and laboriousness, achieving low resistance, improving service life, and reducing space for use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

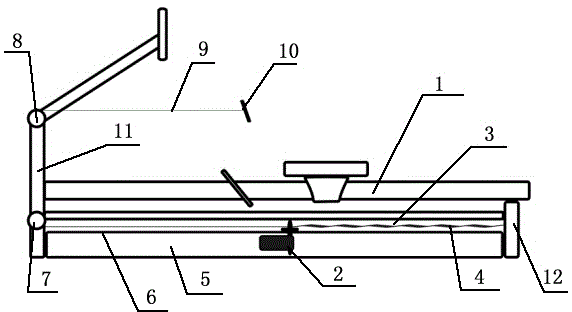

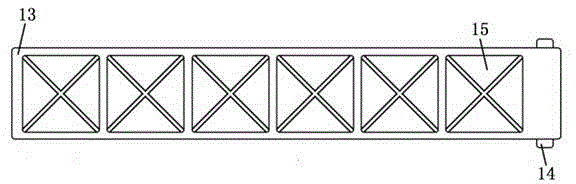

[0022] Embodiment 1: with reference to attached Figure 1-2 , a water resistance rowing machine, comprising a hull 1, paddles 13 and rails 6, a pedal and a seat are arranged in the hull 1, a cavity 3 is arranged at the bottom of the hull 1, and a pool 5 is arranged outside the cavity 3 at the bottom of the hull 1, The bottom surface of the cavity 3 is provided with a track 6 that communicates with the outside of the cavity 3 and the bottom of the hull 1. A sliding device 2 is arranged in the track 6, and the bottom of the sliding device 2 passes through the track 6 and is immersed in the pool 5. The upper part of the sliding device 2 Located in the cavity 3, one end of the upper part of the sliding device 2 is connected to the elastic rope 4, and the other end of the elastic rope 4 is connected to the hull 1, and the other end of the upper part of the sliding device 2 in the cavity 3 is connected to the rope 9, and the other end of the rope 9 One end walks around the fixed pul...

Embodiment 2

[0024] Embodiment 2: with reference to attached figure 1 , a water resistance rowing machine, comprising a hull 1, paddles 13 and rails 6, a pedal and a seat are arranged in the hull 1, a cavity 3 is arranged at the bottom of the hull 1, and a pool 5 is arranged outside the cavity 3 at the bottom of the hull 1, The bottom surface of the cavity 3 is provided with a track 6 that communicates with the outside of the cavity 3 and the bottom of the hull 1. A sliding device 2 is arranged in the track 6, and the bottom of the sliding device 2 passes through the track 6 and is immersed in the pool 5. The upper part of the sliding device 2 Located in the cavity 3, one end of the upper part of the sliding device 2 is connected to the elastic rope 4, and the other end of the elastic rope 4 is connected to the rear column 12 of the hull 1, and the other end of the upper part of the sliding device 2 in the cavity 3 is connected to the rope 9, and the other end of the elastic rope 4 is conne...

Embodiment 3

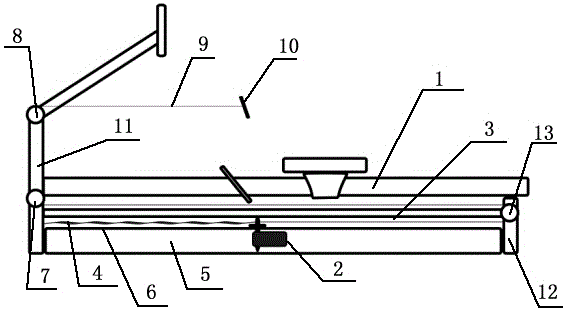

[0028] Embodiment 3: with reference to attached figure 2 , a water resistance rowing machine, comprising a hull 1, paddles 13 and rails 6, a pedal and a seat are arranged in the hull 1, a cavity 3 is arranged at the bottom of the hull 1, and a pool 5 is arranged outside the cavity 3 at the bottom of the hull 1, The bottom surface of the cavity 3 is a track 6 connecting the cavity 3 and the bottom of the hull 1. A slide device 2 is arranged in the track 6, and the lower part of the slide device 2 passes through the track 6 and is submerged in the pool 5. The top of the slide device 2 is located at In the cavity 3, one end of the upper part of the sliding device 2 is connected to the elastic rope 4, and the other end of the elastic rope 4 is connected to the front column 11 of the hull 1, and the other end of the upper part of the sliding device 2 in the cavity 3 is connected to the rope 9, and the other end of the rope 9 Go around two fixed pulleys 7,8 on the front column 11 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com