A kind of aluminum-plastic film for encapsulating lithium battery with oleophobic treatment on the surface and its preparation process

A preparation process and technology for lithium batteries, which are applied in small-sized batteries/battery packs, large-sized batteries/battery packs, battery pack components, etc. Pay attention to material drawing performance and other issues to achieve the effect of enhancing slipperiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

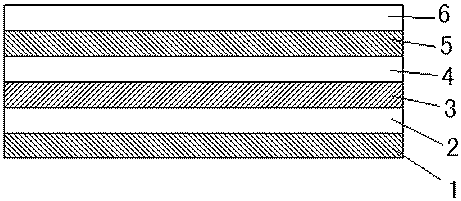

[0023] Attached below figure 1 The present invention is further described, and the protection scope of the present invention includes but is not limited thereto.

[0024] The Chinese names of materials represented by English letters in the present invention are as follows: CPP-casting polypropylene; BPO-benzoyl peroxide.

[0025] like figure 1 As shown, an aluminum-plastic film for encapsulating lithium batteries with an oleophobic treatment on the surface of the present invention includes a CPP layer 1, an inner adhesive layer 2, an aluminum foil layer 3, an outer adhesive layer 4, and a nylon layer arranged in sequence from the inside to the outside. layer 5 and an oleophobic protective layer 6, the oleophobic protective layer 6 includes a fluorine element modified coating, a silicon element modified coating or a fluorosilicon co-modified coating.

[0026] The coating thickness of the oleophobic protective layer 6 is 0.2 μm-2 μm, preferably 0.5 μm-1 μm.

[0027] The thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com