Permanent magnet segmented PWM array sine wave disc type motor

A disc motor and permanent magnet technology, which is applied in the field of sine wave disc permanent magnet synchronous motor and permanent magnet segmental PWM arrangement sine wave disc motor, can solve the difficulty of increasing the processing of permanent magnets, different magnetization directions, Problems such as difficulty in installing the rotor, simplifies the installation process, reduces harmonic components, and facilitates processing and design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

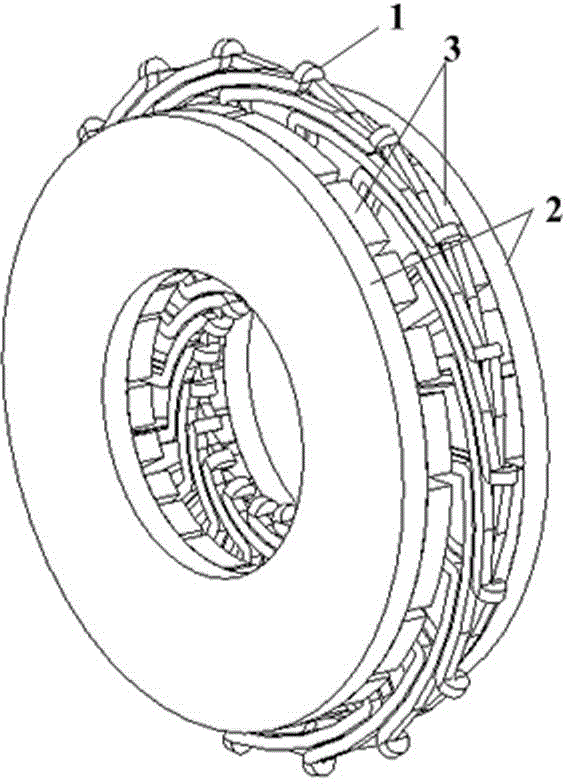

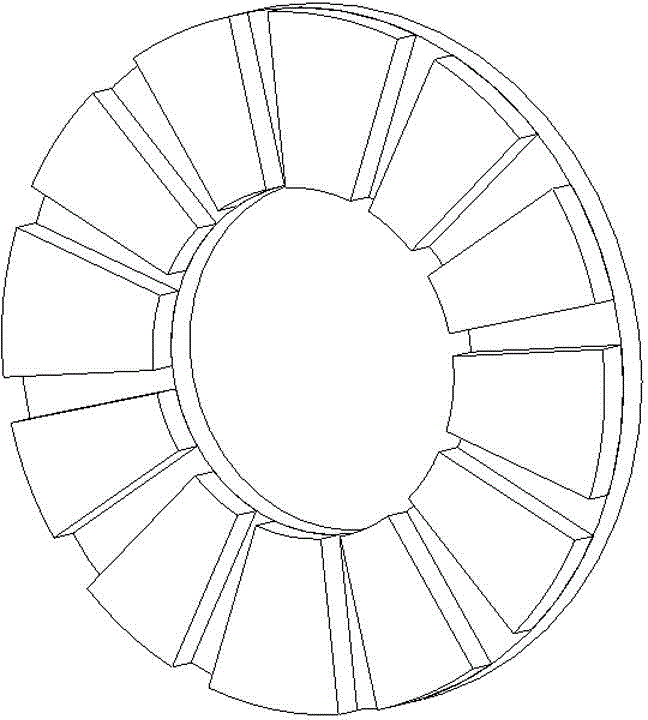

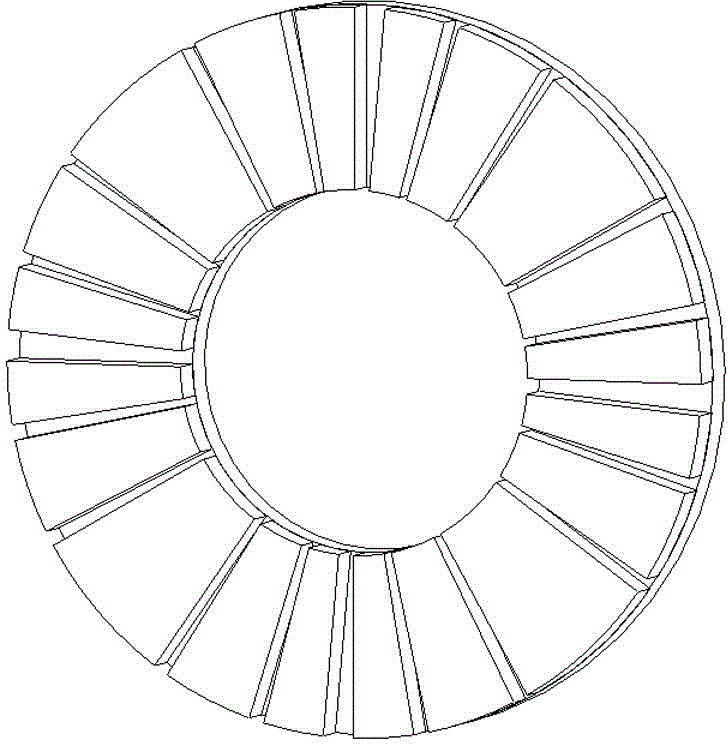

[0027] Refer to attached Figure 1~4 , the permanent magnet segmented PWM arrangement sine wave disc motor of the present invention comprises a rotor disc, a stator disc and a permanent magnet, the permanent magnet is installed on the rotor disc; the stator disc is installed between two rotor discs, and the number of the rotor disc is more The number is at least one more, the stator disk and the rotor disk are installed coaxially, and the stator disk and the rotor disk are arranged alternately in the axial direction; the permanent magnets of each pole on the rotor disk are arranged in segments, and the number of permanent magnet segments under each pole is an odd number. The width of the segment permanent magnets is determined according to the pulse width modulation (PWM) principle.

[0028] 2k+1 permanent magnets are installed on each pole of the rotor, where k is a positive integer greater than zero, the k+1th permanent magnet is installed at the center line of each pole, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com